Maintaining your outdoor machinery is essential for ensuring its longevity and performance. A clear understanding of its various elements and how they function together can make repairs and servicing much easier. By recognizing the different components and their roles, you can identify issues before they become major problems, saving both time and money.

In this guide, we will provide a detailed overview of the key components involved in the operation of your equipment. By familiarizing yourself with the structure and arrangement of each part, you’ll be able to perform routine checks, identify necessary replacements, and understand the overall assembly. Whether you’re a seasoned user or new to equipment maintenance, this information will prove valuable in keeping your machine running smoothly.

Understanding the internal layout of your machinery is crucial for troubleshooting and repairs. With the right knowledge, you can confidently handle maintenance tasks, ensuring that everything operates at its peak performance. This guide will serve as a useful reference to help you identify specific parts and their functions within the system.

Understanding the John Deere 826 Parts

To ensure smooth operation of your outdoor equipment, it is essential to become familiar with its internal components. Each individual element has a specific function that contributes to the overall efficiency of the machine. A well-maintained system helps prevent malfunctions and ensures that the equipment can handle demanding tasks, such as clearing snow or debris.

Main Components and Their Functions

The key elements of this machinery work together to achieve optimal performance. These include the engine, control mechanisms, and different moving parts that engage during operation. Understanding how each component interacts can make it easier to diagnose potential issues. When a certain part fails, recognizing the malfunction allows for faster and more precise repairs, reducing downtime.

Regular Maintenance and Inspection

Frequent checks of the various components are necessary to keep everything in working order. Ensuring that each part is correctly aligned and free from damage can prevent costly breakdowns. Regular maintenance allows you to spot wear and tear early, providing an opportunity to replace or repair the parts before they cause significant problems. Proper upkeep also extends the life of your equipment, making it a worthwhile investment.

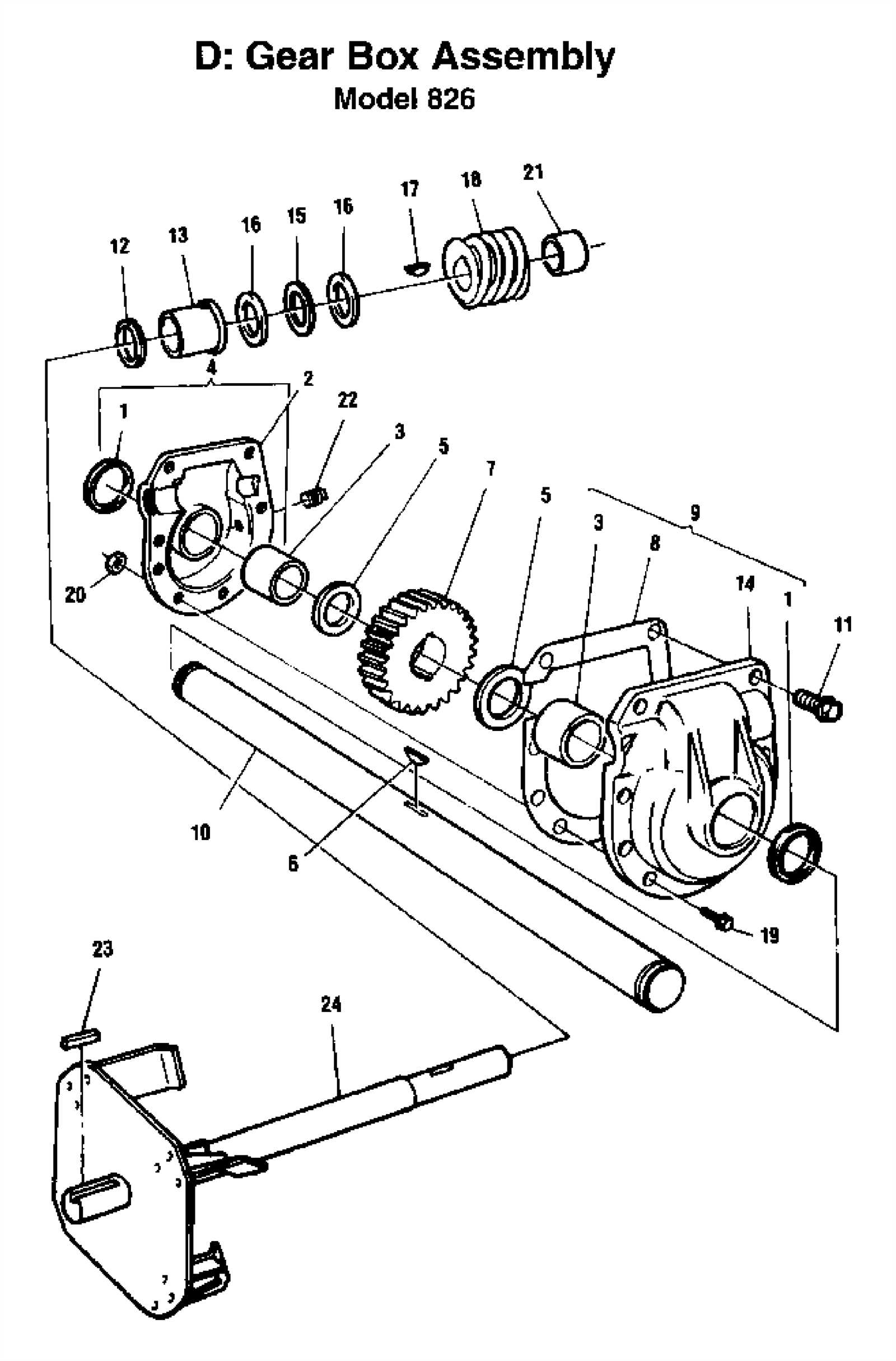

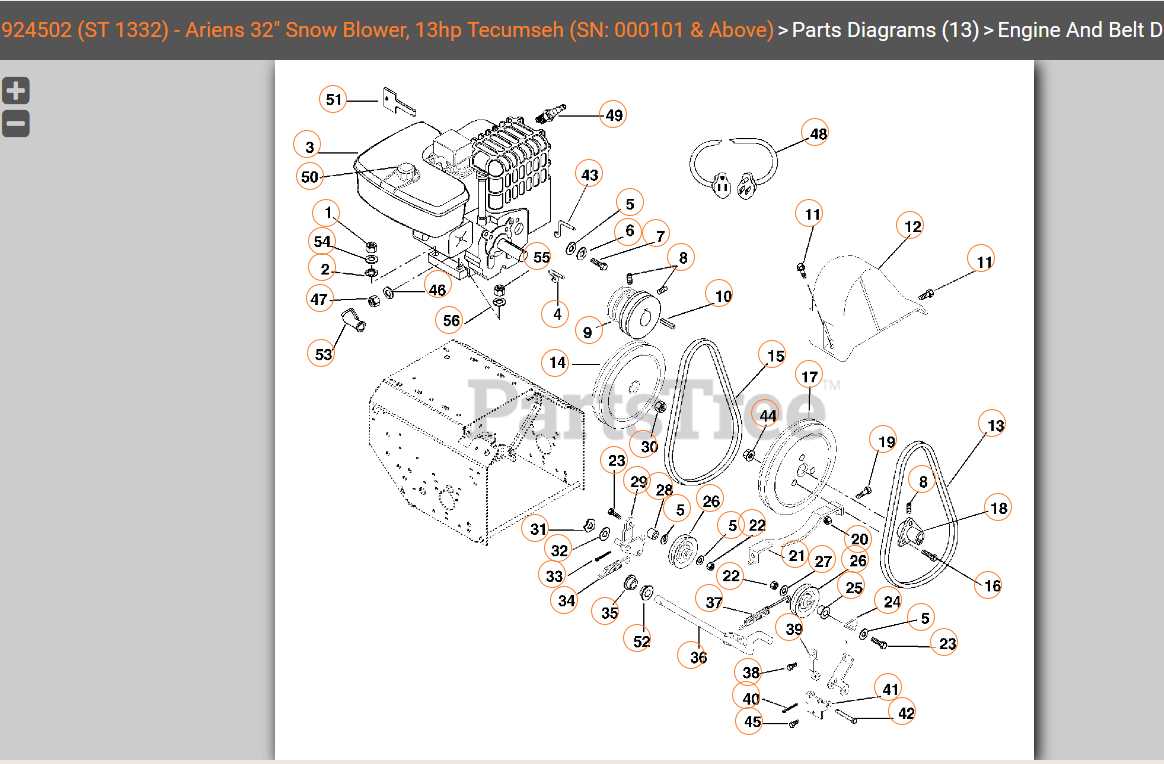

How to Read Snowblower Parts Diagram

Understanding technical drawings is an important skill when working with machinery. These visual guides break down complex systems into easy-to-understand representations, helping users identify components and their relationships. Knowing how to interpret these schematics allows for more efficient repairs, as you can quickly locate and understand the function of each part.

Identifying Key Components

Each element on the diagram is labeled with specific numbers or letters that correspond to individual components. The lines connecting the parts show how they are interconnected, which is crucial for understanding the workflow of the system. Recognizing the shape and position of each component will help you follow the assembly process or identify the area where a malfunction might have occurred.

Interpreting Symbols and Notations

Most diagrams use standardized symbols to represent various types of components, such as fasteners, electrical connections, and moving elements. Familiarizing yourself with these symbols is essential for accurate interpretation. The accompanying legend or key will usually explain what each symbol or notation represents, helping you navigate the schematic with ease and make informed decisions when servicing your equipment.

Common Issues and Replacement Parts

Every machine will eventually experience wear and tear, especially when used in demanding conditions. Identifying common issues early on can prevent more severe damage and extend the lifespan of your equipment. Regular inspection is crucial for detecting these issues, ensuring that repairs can be done before the problem worsens.

Frequent Problems and Causes

One of the most common issues involves clogging in the intake or output areas, especially after prolonged use in wet or heavy snow. This can result in poor performance or even engine strain. Another frequent problem is the wearing down of moving parts like belts or augers, which can lead to decreased efficiency and potential malfunction. Improper maintenance, such as failing to lubricate parts or clean debris, can also contribute to system failures.

Replacement and Maintenance Tips

When replacing worn components, it’s important to use high-quality replacements that match the specifications of the original parts. Regularly checking and replacing items such as belts, spark plugs, and air filters can greatly improve performance. Additionally, maintaining a consistent schedule for lubrication and cleaning can help avoid most common malfunctions, ensuring that your equipment remains in top working condition.