Maintaining complex machinery requires a clear understanding of its internal components and how they interact. Having a detailed visual reference can significantly ease the process of repairs and regular maintenance. Knowing the layout of key elements and their functions can save time and reduce the risk of errors during upkeep.

Accurate visual guides are invaluable for both seasoned technicians and those new to agricultural machinery. They offer a clear representation of how parts are arranged and can help in identifying any damaged or worn-out components. Whether you’re fixing minor issues or conducting a thorough inspection, such resources prove essential.

In this section, we will explore a comprehensive breakdown of the equipment’s key elements. By familiarizing yourself with these parts, you can ensure the longevity and efficiency of your machine, ultimately improving its performance and reliability.

Understanding Agricultural Equipment Components

Effective machinery operation heavily relies on the precise function of its individual elements. Each component plays a specific role in ensuring smooth and efficient performance. Gaining insight into how these elements interact within the system allows for better care, troubleshooting, and maintenance.

Internal mechanisms consist of various interconnected sections, each designed to handle specific tasks. Understanding their layout and purpose is crucial for identifying potential issues early on. Regular inspection and knowledge of each part’s role contribute significantly to minimizing downtime and enhancing the overall lifespan of the machine.

By recognizing how each element contributes to the functioning of the whole, operators can make informed decisions when dealing with maintenance tasks. Whether it’s replacing a worn component or diagnosing a malfunction, having a clear understanding of the system structure is an essential part of ensuring optimal performance.

How to Read an Equipment Layout Guide

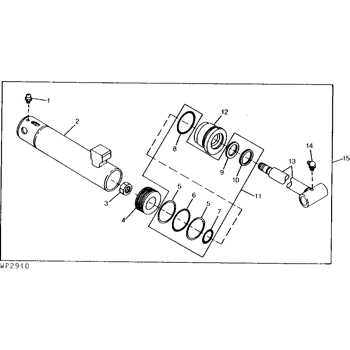

Interpreting visual schematics is an essential skill for anyone looking to repair or maintain complex machinery. These guides provide a detailed map of the system’s internal structure, helping you identify and locate specific elements. Understanding how to read these visuals ensures you can navigate through the components effectively and troubleshoot with accuracy.

Familiarizing Yourself with Symbols

Each schematic uses a set of symbols to represent various parts and connections. These symbols may vary by manufacturer, but their purpose remains the same: to simplify complex systems into recognizable shapes. Knowing what each symbol means will allow you to quickly pinpoint key components and understand their relationship with one another.

Understanding Connections and Labels

The lines and arrows in a schematic indicate how different parts are connected and interact with each other. Labels placed next to the components provide additional details, such as part numbers or specifications, making it easier to identify specific items for replacement or repair. Pay close attention to these markings, as they can guide you in obtaining the right parts or understanding potential issues within the system.

Essential Components of Agricultural Equipment

Every machine relies on a series of critical components that work in unison to ensure optimal operation. Understanding these core elements is vital for efficient performance and troubleshooting. These key sections are designed to handle specific tasks, and their proper functioning is crucial for the smooth running of the entire system.

Powertrain and Engine

The powertrain is the heart of the machine, transmitting power from the engine to other parts. The engine itself, with its intricate components, is responsible for generating the force needed for various functions. Regular maintenance of these sections is essential to avoid performance issues and ensure reliability over time.

Hydraulic System

The hydraulic system is responsible for operating various attachments and systems within the machine. It utilizes fluid power to generate force, enabling movements that are otherwise not possible with mechanical systems alone. Keeping this system in top condition is crucial for maintaining flexibility and efficiency in heavy-duty tasks.