Maintaining a complex piece of equipment requires a clear understanding of its internal structure and the role each element plays in its overall functionality. Whether you are a professional technician or an owner, recognizing the importance of every individual part is essential for ensuring smooth operation and longevity.

With a detailed reference to all key components, identifying potential issues becomes easier, enabling better decision-making when performing repairs or upgrades. By familiarizing yourself with each section, you can address maintenance needs more efficiently and avoid common mistakes that may arise during repairs.

Expert knowledge in machinery layouts not only simplifies diagnostics but also saves time and effort when troubleshooting. Understanding the specific arrangement of each part leads to a more streamlined repair process, resulting in fewer complications and improved performance.

Essential Parts for John Deere E140

For any piece of machinery, it is crucial to understand the primary components that ensure its proper operation. These key elements work together to keep the equipment functioning efficiently, from the engine to the wheels. Each part plays a distinct role, and knowing their functions can help in both maintenance and troubleshooting.

Among the most important components are the transmission system, the cutting deck, and the engine. The transmission controls the movement of the machine, while the cutting deck is responsible for the core task of lawn care. The engine is the powerhouse, driving all other functions and maintaining performance throughout its use.

By familiarizing yourself with these essential elements, you can better manage routine checks and repairs. Keeping a close eye on their condition helps avoid major breakdowns and ensures that the machine performs at its best for years to come.

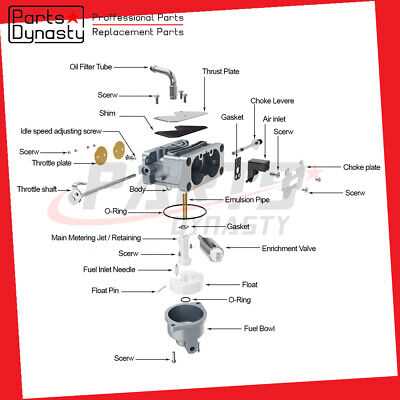

Understanding the E140 Diagram Layout

When working with complex machinery, a clear and organized layout of its structure is essential for efficient maintenance and repair. The layout helps to visualize the arrangement of all key components, allowing for quick identification of any issues or necessary adjustments. Understanding the overall system and how each part interacts is crucial for troubleshooting and ensuring optimal performance.

Component Placement and Function

The arrangement of each element within the machine follows a logical pattern, with each component serving a specific function. For instance, major systems like the drivetrain and engine are located in accessible areas for ease of maintenance. By examining the layout, one can easily pinpoint where each part fits into the system and how they work together to achieve the desired operation.

Visualizing the Entire Assembly

Having a visual reference of the entire assembly can significantly improve the repair process. It allows technicians and users to cross-check individual parts with their corresponding locations, ensuring that nothing is overlooked during inspection or replacement. Such a layout acts as a guide to effectively navigate the system and address any potential concerns with precision.

Common Maintenance Issues and Solutions

Regular upkeep of machinery is vital to ensuring its longevity and optimal performance. Over time, certain parts may wear out or become damaged, leading to potential issues that can hinder efficiency. Identifying and addressing these common problems early can prevent more serious complications and reduce downtime.

One frequent issue is with the cutting mechanism, which may lose efficiency due to dull blades or blockages. Regularly checking and replacing the blades ensures a clean cut and maintains overall system performance. Another common problem involves the engine’s fuel system, which may become clogged or require periodic cleaning to maintain proper fuel flow and prevent starting issues.

Finally, the electrical components are often a source of trouble, with loose connections or worn-out wires causing intermittent functionality. Ensuring that all electrical connections are secure and inspecting the wiring for signs of wear can prevent unexpected malfunctions and extend the equipment’s useful life.