When working with complex machinery, understanding how each element functions together is crucial for effective maintenance and repair. A clear representation of the various components can greatly aid in identifying issues and improving overall efficiency. Each machine has a unique structure, and knowing the role of each section ensures better performance over time.

In this section, we will explore how to interpret the layout of various mechanical parts, focusing on essential connections and functions. Whether you’re troubleshooting or performing routine upkeep, a thorough understanding of these key elements is essential. Clarity and precision in identifying the parts can save time and enhance your repair strategies.

Through detailed illustrations and descriptions, you will gain insights into maintaining your equipment with confidence. Proper knowledge and attention to detail are necessary for any technician or operator aiming to keep their machinery in top condition.

Understanding the Components of the Machinery

In any mechanical system, the interaction between different elements plays a crucial role in ensuring smooth operation. By analyzing the structure and function of each individual component, operators and technicians can better manage maintenance tasks and identify potential issues. A comprehensive understanding of these elements is key to keeping machinery in optimal working condition.

Key Functional Elements

The core elements that make up the system are carefully designed to work in harmony. Each section has a specific function, whether it’s to power the machine, regulate movement, or ensure safety. By studying these components, one can understand how they work together and how they affect overall performance.

Importance of Regular Inspections

Frequent checks and maintenance of these critical components can prevent malfunctions and extend the life of the equipment. Understanding how each element contributes to the entire system allows for more effective diagnosis and repair. Operators should be able to pinpoint areas that need attention before problems become severe, ensuring that the machinery remains reliable and efficient.

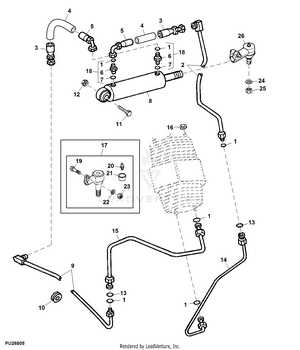

Identifying Key Parts in the Layout

When analyzing a technical blueprint, recognizing the main components is crucial for understanding the overall function and structure of the machine. Each labeled section highlights specific elements, making it easier to identify their roles within the system. Knowing how to read and interpret these markers is essential for both maintenance and troubleshooting tasks.

Focus on Primary Components

The primary elements of the system are often highlighted to draw attention to their importance. These components are critical for the operation, and knowing their location and function ensures that technicians can make informed decisions during repairs. Pay close attention to areas that require frequent maintenance or are prone to wear.

Connection Points and Interactions

Beyond individual components, understanding how they interact is just as vital. The layout will show various connection points, such as linkages or wiring, that allow different parts to function together. Recognizing these connections can help diagnose issues more quickly and ensure proper alignment during repairs or upgrades.

Maintenance Tips for Key Components

Proper care and regular maintenance are essential to ensure the longevity and efficient functioning of any mechanical system. By focusing on the critical elements, operators can prevent unnecessary breakdowns and enhance the machine’s overall performance. Knowing the right maintenance steps is essential for keeping everything running smoothly and avoiding costly repairs.

Routine Inspections

One of the most important aspects of upkeep is performing routine inspections. Check for any signs of wear, corrosion, or loose connections. Regularly inspecting the key components ensures that potential problems are identified early before they affect the system’s performance.

Lubrication and Cleaning

Maintaining proper lubrication and keeping components clean is vital for smooth operation. Apply the correct lubricants to moving parts to minimize friction and prevent wear. Additionally, cleaning the components regularly ensures that dirt and debris do not obstruct their function, preventing unnecessary damage.