Every lawn tractor consists of various essential elements that ensure smooth performance and functionality. Proper knowledge of these components helps owners maintain their equipment efficiently, avoiding costly repairs. Recognizing each part’s function allows for better upkeep and longer-lasting use.

Maintenance becomes easier when you have access to a detailed visual guide that outlines the various sections of your machine. These illustrations simplify identifying specific components, enabling quick repairs or replacements. With the right understanding, managing the machine’s upkeep becomes much more straightforward.

Proper identification and care of key elements contribute to the overall performance of the machine. Whether you’re replacing a worn-out component or conducting routine checks, a comprehensive reference serves as a valuable tool for optimal machine care.

Understanding Lawn Tractor Components

A lawn tractor is made up of a wide variety of parts that all play specific roles in its functionality. Understanding how each component interacts with the others is essential for efficient operation and maintenance. From the engine to the wheels, every section has a crucial role in ensuring your machine runs smoothly and reliably.

Familiarity with the major components, such as the drivetrain, steering mechanism, and cutting system, allows for easier troubleshooting and upkeep. Each part is designed to contribute to the overall efficiency and performance of the vehicle, making it essential to know where they are located and how they function. With this knowledge, operators can ensure that all systems are in good working condition.

Moreover, identifying common wear and tear in these elements and addressing it promptly can help prevent larger issues down the road. Regular inspection of these components will not only extend the life of your equipment but also improve its performance during use. Knowing how to properly maintain these essential elements is key to maximizing the potential of your machine.

Identifying Key Parts for Maintenance

Maintaining a machine requires knowing which components are critical to its performance. Certain elements undergo more wear and tear than others and should be prioritized during routine checks. Understanding which areas need regular inspection will help ensure smooth operation and reduce the chances of unexpected breakdowns.

Engine and Fuel System

The engine is the heart of any machine, and its condition directly affects overall performance. Regular inspection of the engine components, such as the air filter, spark plugs, and fuel lines, ensures that the engine runs efficiently. A clean air filter and properly functioning spark plugs can prevent power loss and misfires, while fuel system maintenance ensures proper combustion and fuel efficiency.

Drive System and Transmission

The drive system is another key area that requires frequent attention. This includes checking belts, pulleys, and the transmission for signs of wear. Keeping these parts in top condition prevents slipping or power loss, ensuring smooth movement. A well-maintained drive system contributes to reliable performance and extends the life of the machine.

Identifying and maintaining these critical components can prevent costly repairs and keep your machine running optimally. Regular checks for wear and proper lubrication can significantly reduce the chances of breakdowns, making routine maintenance an essential part of ownership.

How to Use the Parts Diagram Effectively

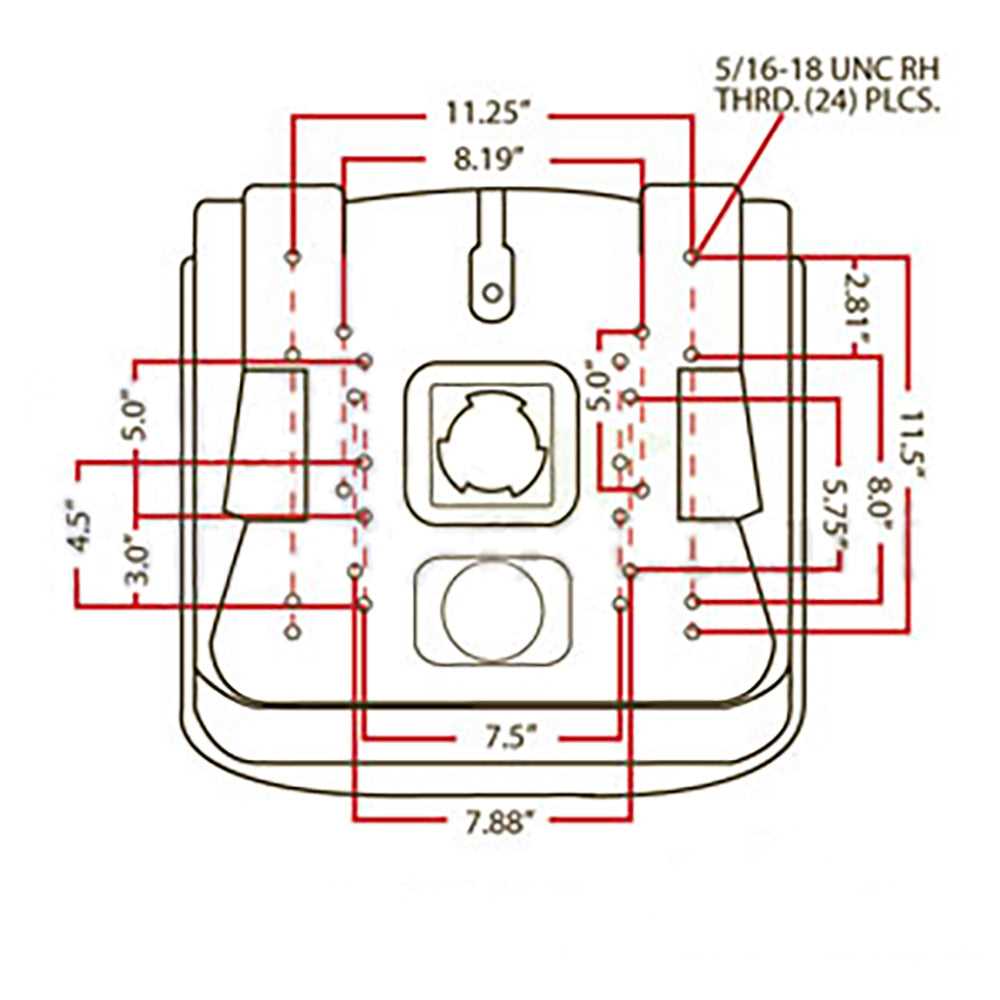

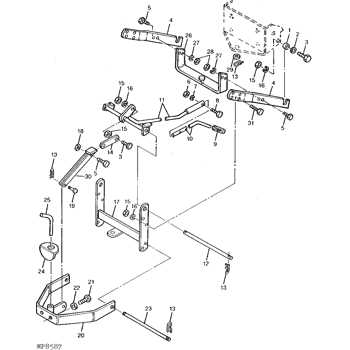

Utilizing a visual guide of a machine’s components can greatly enhance your ability to perform repairs and maintenance. These illustrations provide clear depictions of each section, helping you quickly identify the necessary parts and their locations. Knowing how to navigate this guide allows you to address issues with precision, ensuring that the right components are replaced or repaired without confusion.

When using a reference guide, begin by familiarizing yourself with the layout and labeling system. Each component is typically marked with a unique number or label, making it easier to cross-reference with the manual or parts list. By understanding the numbering and structure, you can quickly locate the specific section you need to work on, whether you’re repairing a malfunction or upgrading parts.

Effective use of these guides also involves careful attention to the details of each part. Ensure that you are using the most up-to-date version of the reference, as designs may change over time. When you have a clear understanding of the layout and function of each part, performing maintenance becomes more efficient and less prone to errors, leading to longer-lasting performance.