Maintaining a lawn mower requires a clear understanding of its essential components and how they work together to ensure efficient performance. Whether you’re replacing worn-out parts or troubleshooting mechanical issues, knowing each part’s function is crucial for keeping your equipment in top shape.

Every lawn mower is made up of several key elements that contribute to its ability to operate smoothly. These elements can wear down over time, requiring replacement or repair. Understanding the layout and identifying specific components will help you make the right decisions when it comes to maintenance and repairs.

By familiarizing yourself with your mower’s construction, you can prevent unnecessary damage, improve its longevity, and save on costly repairs. Proper knowledge of these components will empower you to tackle maintenance tasks with confidence, ensuring your mower works efficiently for years to come.

Understanding Lawn Mower Components

When it comes to maintaining and operating a lawn mower, understanding its individual elements is essential for effective repair and upkeep. Each part plays a specific role, contributing to the overall functionality and performance. Familiarity with these components allows for easier identification of issues and ensures that replacements or adjustments are made accurately and efficiently.

Key Elements of the Mower Assembly

The mower’s assembly is composed of various mechanical parts that work in harmony to achieve the desired results. This includes the engine, blade system, transmission, and support structure. These components interact in such a way that any malfunction in one can affect the entire machine’s efficiency. Understanding how each part contributes to the mower’s operation will help you make informed decisions when maintenance is required.

Identifying Worn or Damaged Components

Regular inspection is crucial for detecting worn or damaged parts that may need replacement. For example, blades and belts are subject to wear due to constant friction and usage. Identifying early signs of damage, such as unusual vibrations or poor cutting performance, will help prevent more serious issues from arising. Ensuring the proper functioning of each part not only extends the mower’s lifespan but also improves its cutting efficiency.

How to Read the Components Layout

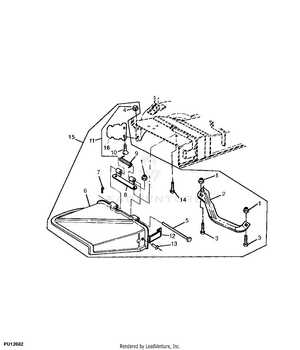

Understanding how to read a component layout is crucial when it comes to servicing or repairing equipment. These layouts provide a visual representation of how parts are arranged and interconnected within the machinery. Properly interpreting these schematics ensures that you can locate the right components, understand their function, and identify where issues may arise.

Typically, the layout will use labels and symbols to distinguish each part, often with numbers or codes associated with specific components. Familiarizing yourself with these markings will help you navigate the diagram more efficiently. In many cases, the diagram will also highlight the orientation and placement of each element to ensure proper assembly during repairs.

It’s important to look for key details like part sizes, shapes, and locations within the layout. This knowledge will guide you in ordering replacements and ensure that each part is installed in the correct position. By practicing with these layouts, you’ll gain confidence in making the right decisions when servicing your equipment.

Common Replacement Components for Lawn Mowers

Over time, certain components in lawn mowing equipment may wear out or become damaged due to regular use. Replacing these elements promptly helps maintain the overall functionality of the machine. There are several common components that often need to be replaced to ensure optimal performance and extend the mower’s life.

Essential Components for Maintenance

Some of the most frequently replaced components include:

- Blades – These are subject to wear and may become dull or damaged, impacting cutting efficiency.

- Belts – Belts can stretch or break over time, leading to issues with power transmission.

- Filters – Air, oil, and fuel filters may clog, affecting engine performance and fuel efficiency.

- Spindles – These rotating parts can wear out, causing a loss of power or uneven cutting.

- Wheels – Wheels may degrade from constant contact with the ground, affecting mobility and cutting height.

Choosing the Right Replacement

When replacing these components, it’s important to select high-quality parts that are compatible with your equipment. Consult the manufacturer’s recommendations to ensure the right fit and maintain the best performance standards. Replacing worn-out elements with genuine or compatible parts can significantly enhance the mower’s efficiency and durability.