When maintaining any lawn equipment, having a clear understanding of its internal structure is essential. Recognizing the various sections and how they fit together ensures smooth repairs and maintenance. This knowledge helps owners keep their machines in top condition for longer periods.

Identifying individual components and their functions can greatly improve efficiency in troubleshooting issues or replacing worn-out parts. Knowing where each element belongs within the system can save time and effort when addressing problems.

Exploring the intricate arrangement of each section allows users to make informed decisions about repairs and upgrades. Whether it’s for simple fixes or major overhauls, having a visual map of how the equipment works is invaluable for maintaining its functionality.

Understanding the Lawn Tractor Assembly

Proper knowledge of the tractor’s overall design is crucial for ensuring its smooth operation. Every system is interconnected, and each element plays a role in the machine’s performance. A solid understanding of the layout allows users to perform maintenance more effectively and troubleshoot potential issues.

Core Systems and Components

Every machine consists of several core systems that interact with one another to deliver the desired results. These systems include the engine, transmission, and steering, all of which are integral to the functioning of the equipment. Recognizing the purpose of each component helps simplify maintenance tasks.

Maintenance and Troubleshooting

Routine upkeep is essential to extend the life of the equipment. By familiarizing yourself with the layout of the tractor, it’s easier to identify parts that need attention. Regular checks of key components such as the engine, wheels, and belts can prevent unexpected failures and improve performance over time.

Key Components of the Lawn Tractor Model

Each machine relies on several essential elements to operate effectively. These components work in harmony to ensure smooth functioning and efficient performance. Understanding the key systems and their roles helps users maintain and troubleshoot their equipment with ease.

Among the most crucial parts are the engine, transmission, and drive systems. These elements are responsible for powering the vehicle, enabling movement, and ensuring proper handling. Additionally, the steering mechanism and wheel assembly play a vital role in maneuverability, offering precise control during operation.

The cutting system, consisting of blades and associated mechanisms, is another key component. It is designed to handle the main task of trimming grass, and its performance directly affects the quality of the work. Regular inspection of these core elements is important to keep the machinery in optimal condition.

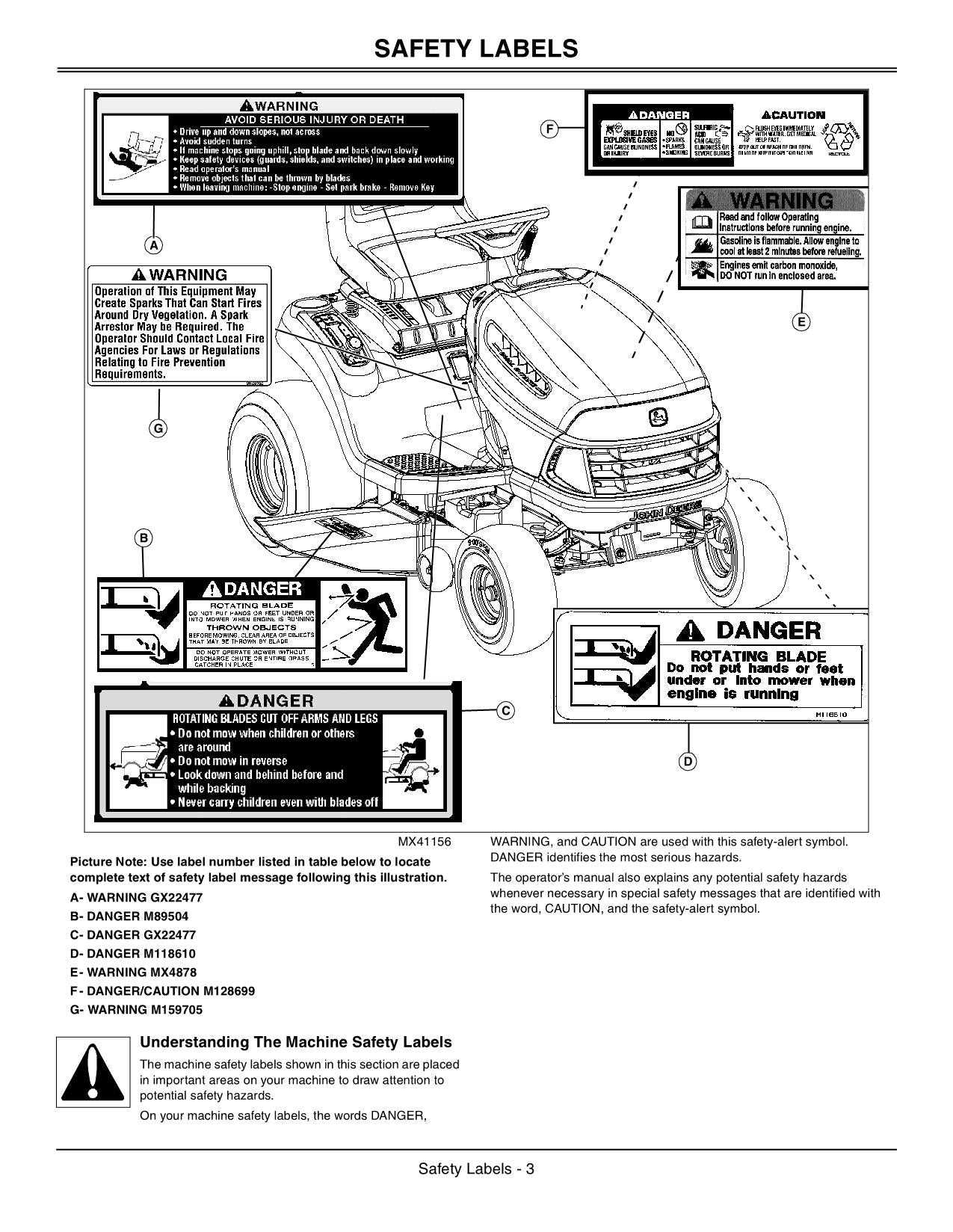

How to Read the Assembly Layout

Understanding how to interpret the layout of a machine is essential for efficient repairs and maintenance. The visual representation of components provides a clear guide to their locations and connections, allowing for easier identification and management of parts.

Start by identifying the various sections and their corresponding symbols or labels. These will indicate specific components and their relationships to one another. Each part is usually numbered or marked with a unique identifier, making it simple to cross-reference with the parts catalog for ordering replacements or performing inspections.

Next, pay attention to the arrangement of the components. The layout typically shows how each part is connected, which helps in understanding the overall structure. This information is invaluable when disassembling or reassembling the machine, ensuring that all components are properly aligned and functioning.