When it comes to maintaining and repairing machinery, having a clear understanding of its internal structure is essential. Every machine is made up of numerous interconnected elements, each playing a crucial role in its overall performance. Knowing how these parts function together can significantly enhance both the efficiency and longevity of your equipment.

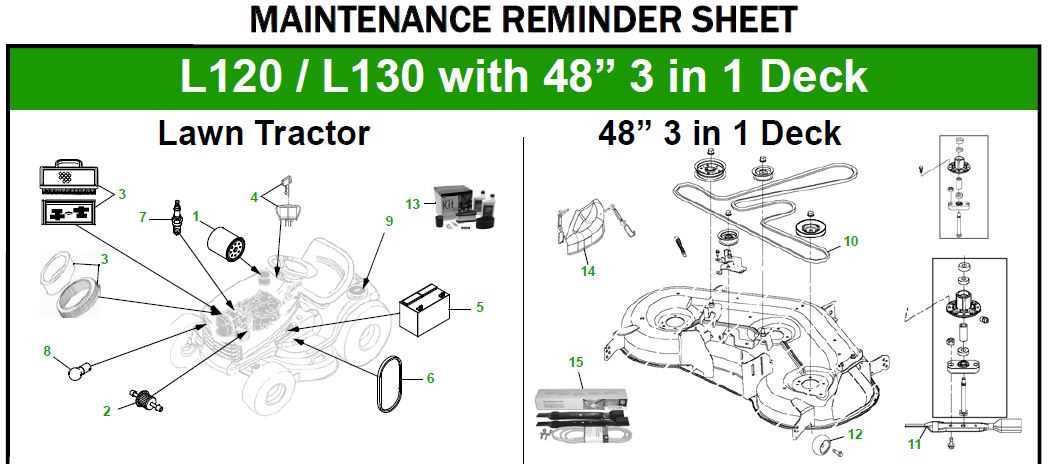

One of the most effective ways to familiarize yourself with the various components is by referring to a detailed schematic. These visual guides can help pinpoint specific parts and provide insight into how they interact, enabling you to carry out repairs and maintenance with precision. Whether you are a professional mechanic or a DIY enthusiast, understanding the layout of your machine’s elements is a valuable skill.

In this article, we will explore the different parts of agricultural machinery, offering an in-depth look at how to use these schematics for better maintenance practices. With the right knowledge and tools, you can ensure that your equipment runs smoothly for years to come.

Understanding Tractor Components

To keep your machinery operating at peak performance, it’s crucial to have a solid understanding of its key components. Every piece of equipment relies on a network of interconnected elements that work together to ensure proper functionality. Recognizing how these individual components contribute to the whole allows you to perform more effective repairs, adjustments, and maintenance tasks.

In this section, we will take a closer look at the essential parts that make up the system, highlighting their purpose and role. Whether you’re tackling minor repairs or major overhauls, knowing the purpose of each element can save both time and resources, making your work more efficient.

Key Components of the System

One of the core aspects to consider is the cutting mechanism, which plays a significant role in the overall operation. These components work in tandem to ensure smooth performance and are often subjected to wear and tear. Additionally, drive systems and linkages are critical for transferring power throughout the machine, ensuring that all parts function correctly.

How Proper Maintenance Improves Efficiency

Regular inspection and maintenance of each component can greatly extend the lifespan of the entire unit. Simple tasks, such as lubrication and tightening fasteners, go a long way in preventing more significant issues down the line. By understanding the components’ interactions, you can prioritize maintenance tasks and address potential problems before they escalate.

Complete Guide to Component Breakdown

Every machine consists of several critical elements that must function together seamlessly for optimal performance. A deep understanding of these components helps in identifying potential issues early and ensuring smooth operation. By breaking down each part, you can gain insight into how each contributes to the overall functionality of the system.

This section will provide a comprehensive breakdown of the major components, explaining their functions and how they interact. Whether you’re maintaining the equipment or troubleshooting a malfunction, this guide will help you understand each element’s role and how to care for it effectively.

Essential Mechanisms of the System

At the heart of the machine are the mechanisms responsible for movement and power transmission. These include the drive systems, which transfer energy from the engine to various parts, and the cutting or working mechanisms, which handle the primary task. Each mechanism is crucial for maintaining consistent operation and preventing excessive wear.

Maintenance Tips for Longevity

Regular checks and maintenance of individual components are vital to extending the life of the machinery. Ensuring that moving parts are properly lubricated, inspecting for wear and tear, and tightening loose connections can prevent more serious issues. Understanding the role of each element allows you to prioritize maintenance tasks and avoid unnecessary downtime.

How to Use the Equipment Component Guide

Having a visual guide for the internal elements of your machinery can be incredibly useful when it comes to repairs and maintenance. These schematics allow you to quickly identify the components, understand their connections, and locate any areas that may need attention. Knowing how to navigate these resources efficiently ensures that you can make the most of them during your work.

In this section, we will walk through the steps of using a schematic to identify and understand key components. By mastering the use of these guides, you can perform repairs with greater accuracy and confidence, reducing the likelihood of errors and minimizing downtime.

Understanding the Layout

The first step in utilizing a schematic effectively is understanding the layout and how the parts are organized. Typically, these guides break down the machinery into sections, with each section representing a group of related components. Familiarizing yourself with these sections allows you to quickly find what you’re looking for, whether it’s a specific part or a set of interconnected elements.

Identifying Components and Functions

Once you understand the layout, the next step is learning to identify the various components and their functions. Each part is typically labeled with a code or number, which corresponds to its description in the reference materials. By cross-referencing these numbers, you can gain a deeper understanding of how each element contributes to the overall operation and performance of the machinery.