When it comes to maintaining agricultural machinery, recognizing the individual components is crucial for optimal performance. The proper identification of each element allows for easier repairs, improved efficiency, and longer-lasting equipment. Having a detailed visual guide can significantly simplify the maintenance process for users, ensuring that every part is in working condition.

Knowing how to read and interpret detailed visuals of machine parts can prevent costly errors and reduce downtime. Whether for repair or regular servicing, understanding the function of each piece helps in troubleshooting potential issues before they escalate. This knowledge is particularly valuable for anyone working with large-scale farming machinery.

With the right resources, recognizing wear and tear or malfunctioning components becomes straightforward. Through this guide, you’ll gain insights into how to identify and replace worn parts, keeping your equipment in top shape and avoiding unnecessary delays during critical seasons.

Understanding Farm Equipment Components

Efficient agricultural machinery relies on a variety of intricate elements working together. Each individual component serves a specific function, contributing to the overall performance of the machine. Knowing the role of each part helps operators ensure everything runs smoothly and can expedite troubleshooting when issues arise.

Key Components for Efficient Operation

In large-scale farming machinery, several essential components work in unison to provide optimal functionality. These key elements range from cutting blades to control mechanisms that regulate movement. Properly understanding their interaction enables operators to maintain the system and keep it running efficiently, reducing downtime and enhancing productivity.

Importance of Regular Inspection and Maintenance

Regular inspection of equipment components ensures that all pieces are functioning as they should. Worn-out or damaged parts can lead to inefficiencies, safety risks, or costly repairs. By keeping a close eye on each section, farmers can identify problems early on, avoiding potential setbacks and maintaining smooth operation throughout the season.

How to Read a Farm Equipment Component Illustration

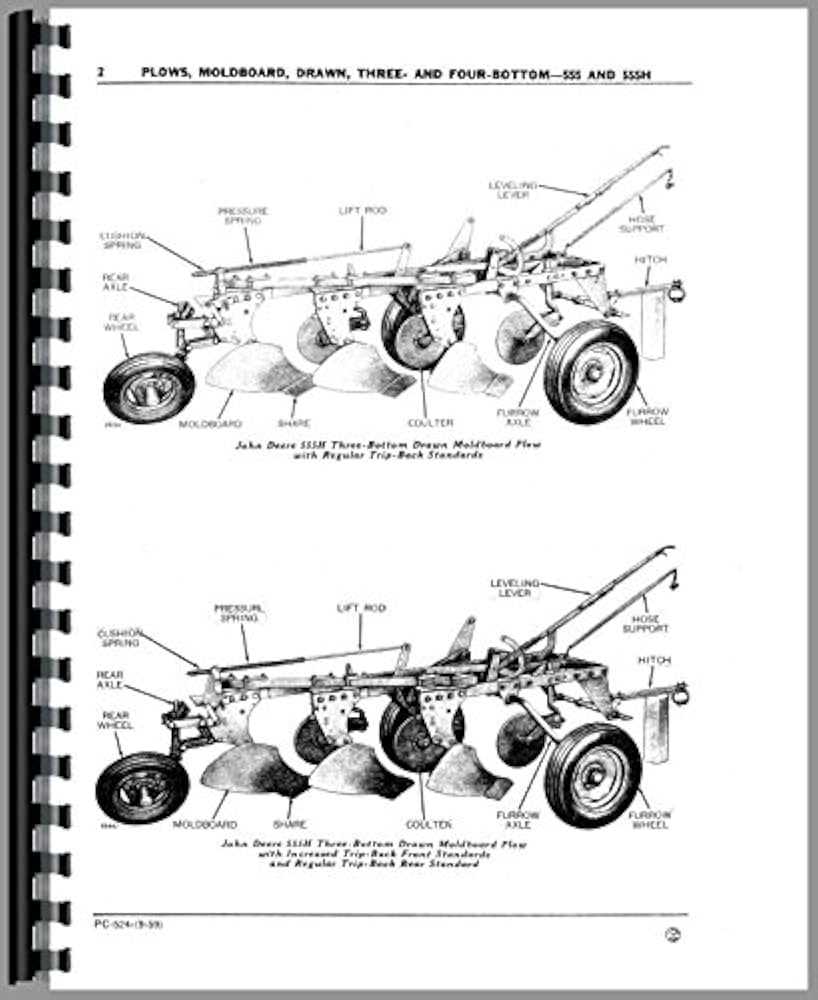

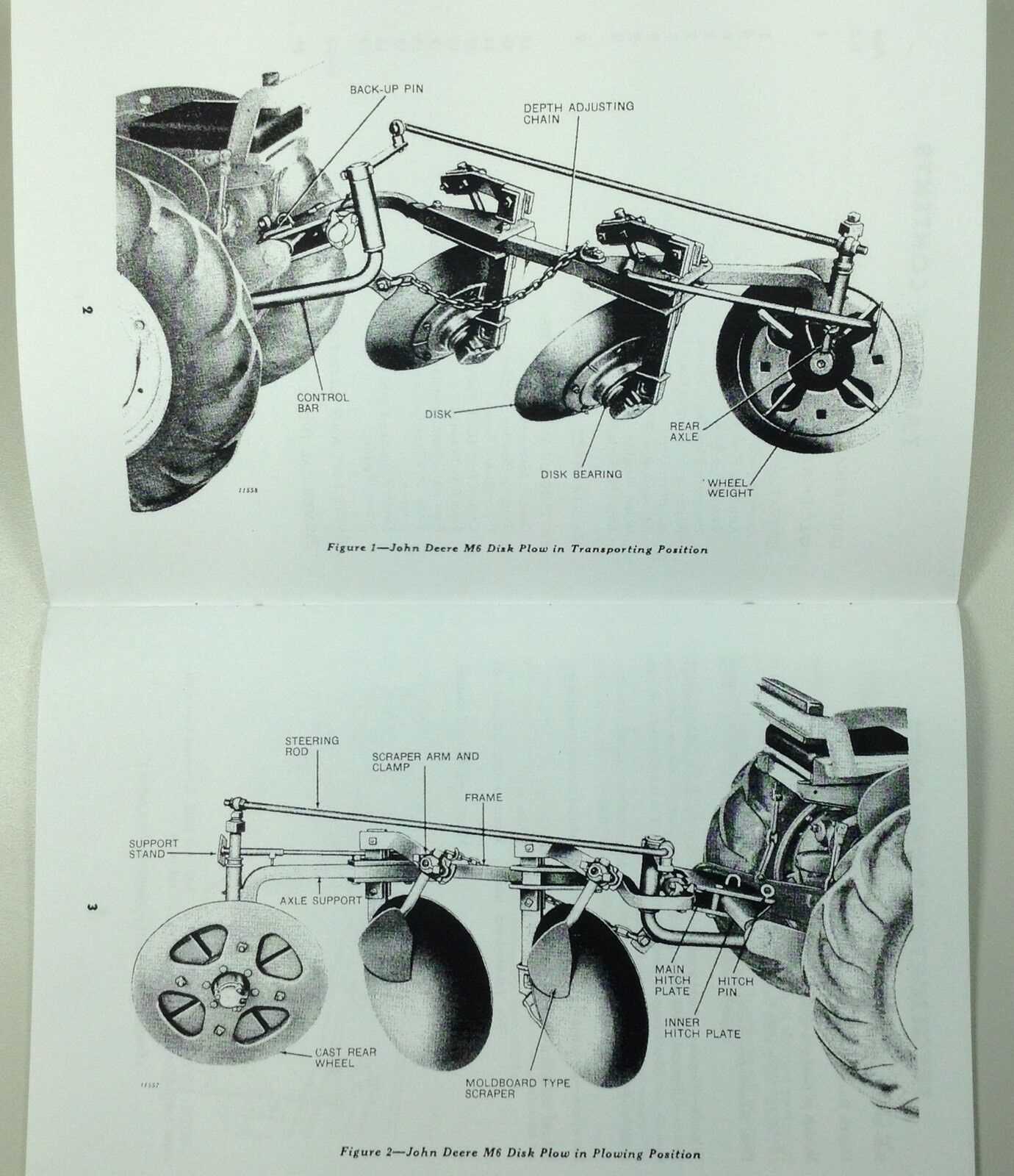

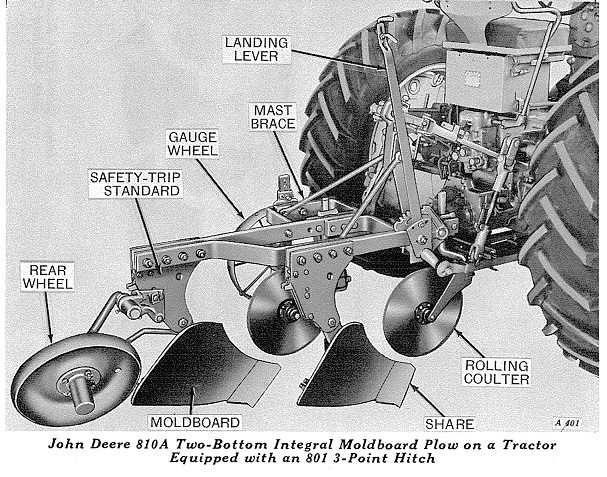

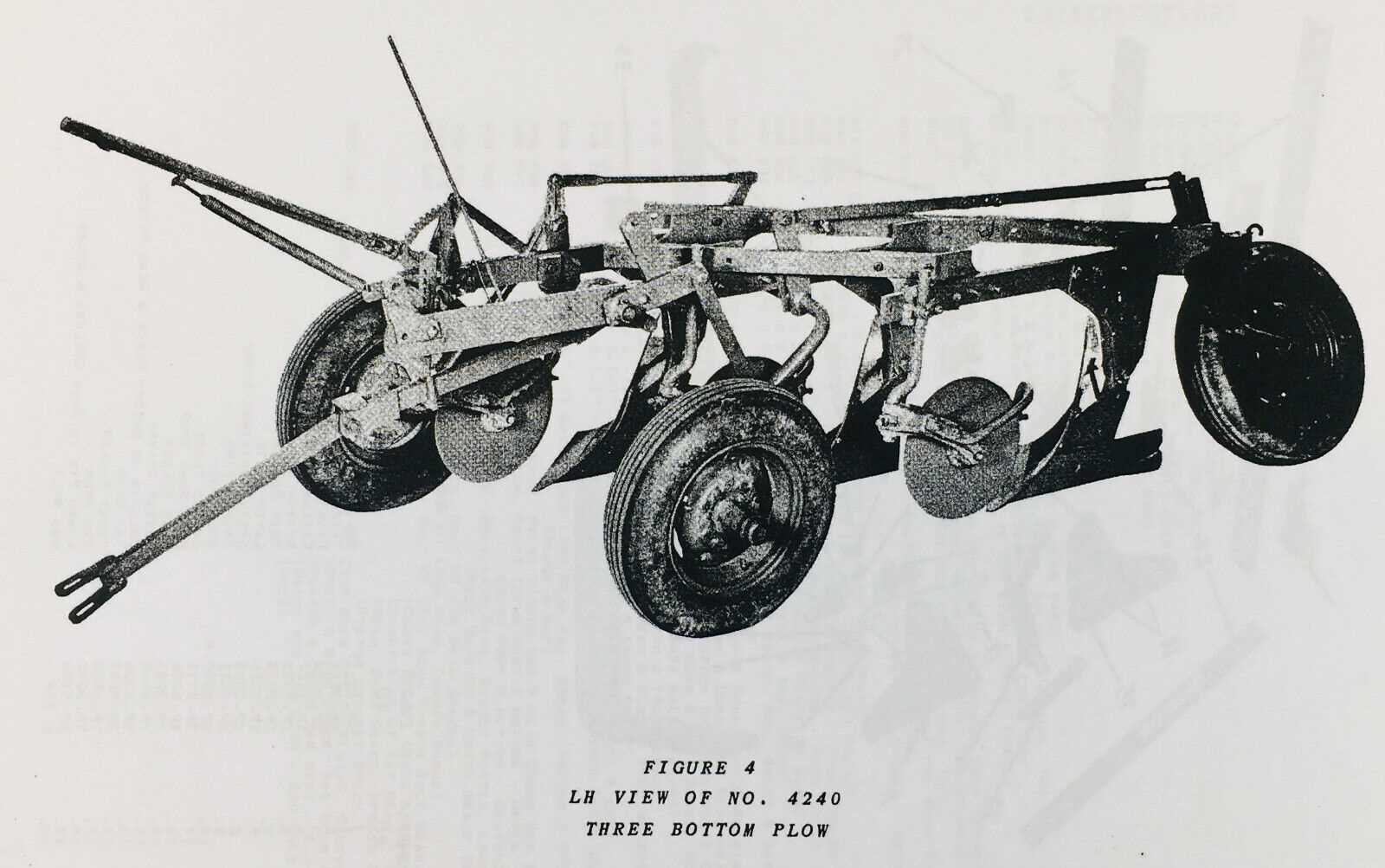

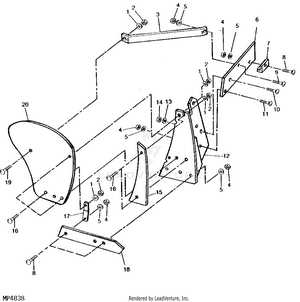

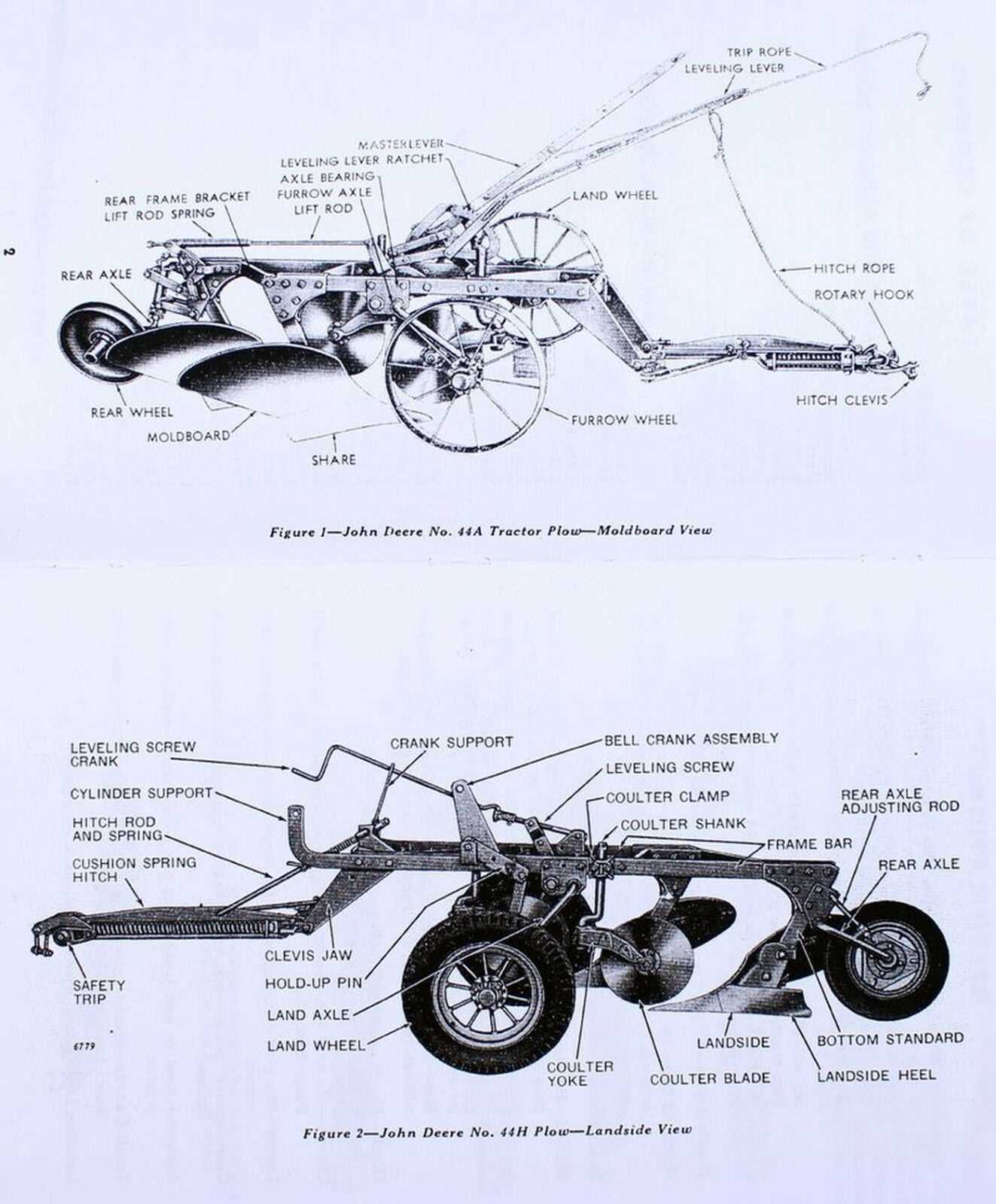

Understanding a visual representation of agricultural machinery is essential for proper maintenance and repair. These illustrations provide a detailed view of how various components fit together, allowing operators to easily identify parts, understand their functions, and spot potential issues. Learning to read these resources accurately is key to efficient troubleshooting and timely repairs.

Identifying Key Features

The first step in interpreting an equipment illustration is recognizing the key features and labels. Each section is typically numbered or marked with letters to correspond to a specific component. Understanding the layout and the symbols used will help users quickly locate and identify the elements that need attention.

Understanding Component Functions

Once the parts are identified, it’s crucial to understand their roles within the system. Each element has a specific function that contributes to the overall performance of the machine. Some parts control movement, while others provide support or stabilization. Knowing the purpose of each piece helps in diagnosing issues and ensuring that every part is functioning as it should.

Common Issues with Agricultural Equipment

When working with farming machinery, operators may encounter various issues that affect performance. These problems can range from minor malfunctions to more serious breakdowns that disrupt operations. Recognizing and addressing these common challenges early is essential for maintaining equipment efficiency and avoiding costly repairs.

One common issue involves wear and tear on key components, which can lead to inefficiencies or even system failure if not addressed promptly. Misalignment or damage to moving parts may cause uneven operation, making it crucial to regularly inspect machinery for signs of deterioration. Additionally, improper maintenance or lack of lubrication can exacerbate these issues, resulting in higher repair costs and more frequent downtime.