When it comes to maintaining and repairing your outdoor machinery, having a clear understanding of its components is crucial. This section offers a detailed overview of all the essential elements that make up your equipment. Whether you’re a seasoned technician or a DIY enthusiast, knowing the layout and function of each part will make your job easier and more efficient.

In this guide, we’ll walk through the various sections of the equipment and highlight the most important pieces that require attention. By familiarizing yourself with these components, you’ll be better equipped to handle any maintenance tasks or troubleshooting challenges that may arise.

Efficient repairs and maintenance are often just a matter of knowing where each element fits and how they interact. This guide is designed to provide a clear visual representation, making it easy to locate and identify the right pieces when needed.

Understanding the layout of your machinery ensures smoother operations and extends the lifespan of the equipment, so you can keep everything running at its best.

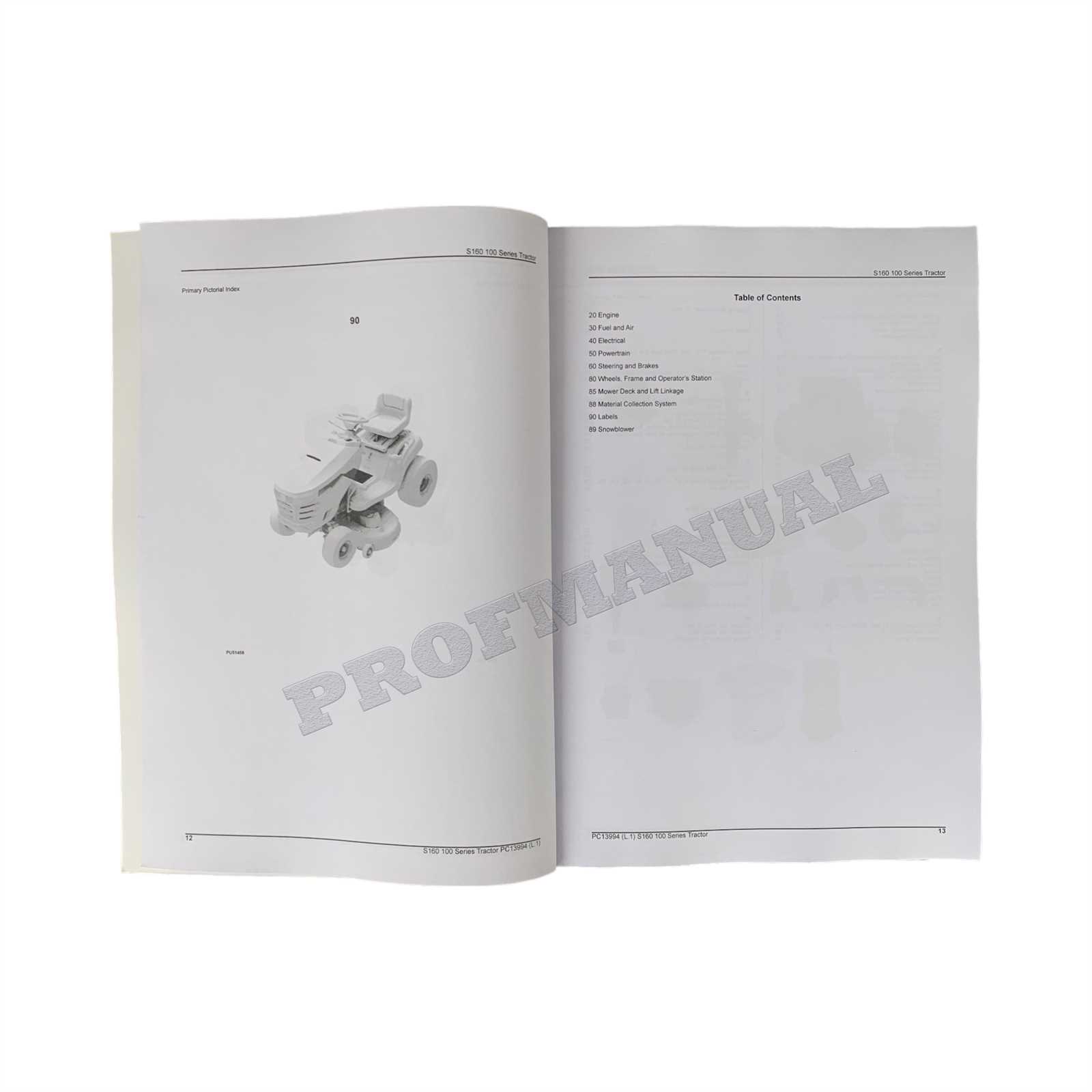

Understanding the John Deere S160 Parts

Every machine is built with multiple interconnected components, each serving a unique purpose in ensuring the smooth operation of the whole system. Recognizing and understanding these key elements can help with proper maintenance, repairs, and troubleshooting. Whether it’s engine components, transmission systems, or electrical elements, each part plays an essential role in the overall functionality of the equipment.

Key Components of Your Equipment

At the heart of any lawn or garden machine is the engine and its related components. These elements require regular inspection to keep the engine running smoothly and efficiently. From spark plugs to air filters, each piece must be in top condition to prevent issues and ensure long-term durability.

Transmission and Drive Systems

Transmission and drive systems are critical to converting power and enabling movement. Understanding how these systems work together ensures better control and handling, which is key to optimal performance. Regular checks and timely repairs in this area can prevent costly breakdowns and prolong the equipment’s life.

Maintenance knowledge of these components allows for proactive care and minimizes the risk of malfunction, making your machine more reliable and cost-effective in the long run.

Familiarity with the machinery’s structure not only simplifies repairs but also improves your ability to troubleshoot problems, ensuring you’re always prepared for unexpected issues. Knowing the layout and function of each part can save you time and effort in maintaining your equipment.

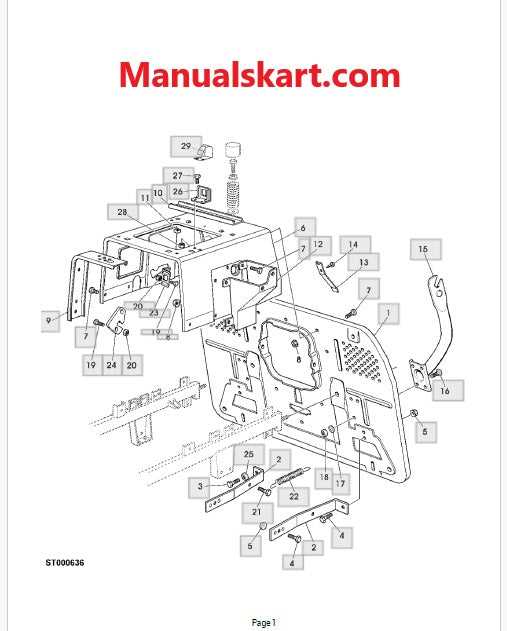

How to Use the S160 Parts Diagram

When it comes to repairing or maintaining your outdoor equipment, a clear visual reference of its components can make all the difference. Using a detailed reference guide allows you to easily locate parts, identify issues, and understand how different elements work together. With the right guide, even complex machines become manageable for both professionals and DIY enthusiasts.

Step-by-Step Process

Start by familiarizing yourself with the layout of the guide. Often, the diagram will be divided into sections based on machine functions, such as the engine, transmission, or electrical systems. Each section will show parts in their correct position, helping you understand where everything belongs. Once you have identified the part you need, you can quickly locate it within the system.

Locating Specific Components

For more complex repairs, search for the part by name or function in the guide. By understanding the part’s role within the system, you’ll be able to quickly pinpoint its location and figure out how to address any issues. Always ensure you reference the correct version of the guide, as different models or revisions may have slight variations in the component setup.

Efficiency comes from using a clear visual guide. With the diagram, repairs are faster and more accurate, allowing you to address issues with minimal downtime.

Using this reference reduces the chance of mistakes, making repairs straightforward and ensuring your machine continues to perform at its best for longer.

Common Issues and Solutions for S160 Parts

Like all mechanical systems, your outdoor equipment can face various challenges over time. Understanding common issues and knowing how to address them is essential to maintaining its efficiency. From wear and tear on crucial components to unexpected malfunctions, knowing the typical problems that arise can help you act quickly and prevent more serious damage.

Engine Performance Problems

One of the most frequent issues encountered is poor engine performance, often due to clogged air filters or worn-out spark plugs. If the engine is misfiring or stalling, it’s important to check these parts first. Replacing a dirty air filter or faulty spark plug is a simple and effective solution to restoring the engine’s power and reliability.

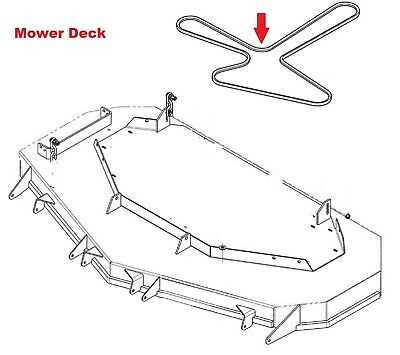

Transmission and Drive Troubles

Transmission issues can also disrupt your equipment’s function, especially if the drive belt becomes worn or damaged. Slipping or irregular movement may be caused by a misaligned or frayed belt. Regular inspection and timely replacement of worn belts can prevent further complications and keep the equipment running smoothly.

Proactive maintenance is key to minimizing these common issues. By regularly checking and replacing essential components, you can extend the lifespan of your equipment and avoid more expensive repairs.

Timely intervention helps address small problems before they turn into major breakdowns, ensuring your machine remains in optimal working condition throughout its life.