Proper maintenance and efficient operation of heavy machinery rely on understanding the individual components that make up the system. Each element plays a crucial role in the overall function, and being familiar with them can significantly improve performance and troubleshooting efforts. This section will help you navigate through the essential components and their respective locations.

Whether you’re replacing a malfunctioning part or simply gaining more knowledge about the equipment, having access to a detailed reference guide is key. Understanding how the pieces fit together is vital for both maintenance and ensuring the equipment operates smoothly during challenging tasks.

Identifying each segment in the machinery setup allows you to work more efficiently and avoid common issues. Recognizing each piece’s role enhances your ability to make informed decisions and keep the equipment running at its best.

Understanding Equipment Components

To effectively operate and maintain heavy-duty machinery, it is essential to understand the various components that form the system. Each element serves a specific function, contributing to the overall efficiency and performance. Recognizing how these pieces interact with one another can lead to better usage and faster troubleshooting in case of issues.

Essential Mechanisms and Their Functions

Every system consists of several key mechanisms that enable it to perform tasks efficiently. These parts range from structural elements to moving parts, each designed for a specific purpose. Whether it’s a motor driving the motion or a hydraulic system ensuring smooth transitions, understanding their roles is crucial for optimal performance.

Maintenance and Troubleshooting

Knowing the components also aids in proper maintenance. Recognizing the signs of wear or malfunction allows for timely interventions, preventing further damage. Regular inspection and awareness of each piece’s function can extend the machinery’s life and reduce unexpected downtime, ensuring that it continues to operate efficiently over time.

Key Components of Snow Plow Systems

Every complex system relies on a variety of interconnected elements, each contributing to the overall functionality. In the case of equipment used for clearing surfaces, it is essential to understand the main components that ensure the system operates smoothly. These crucial parts work in harmony to carry out the necessary tasks effectively, and knowing them helps in both operation and maintenance.

Structural and Functional Elements

The structural framework provides the base for all other components. It supports the machinery and ensures stability during use. Critical systems, such as the lifting mechanism, allow for the movement and adjustment of the working area. Additionally, elements like the control system facilitate interaction between the operator and the machine.

Energy and Motion Systems

To achieve high efficiency, motion is driven by powerful hydraulic systems that enable adjustments and adjustments during operations. These elements, combined with drive motors, ensure that the machinery can perform heavy-duty tasks with precision. Regular checks of these systems are essential to maintain smooth performance and avoid breakdowns.

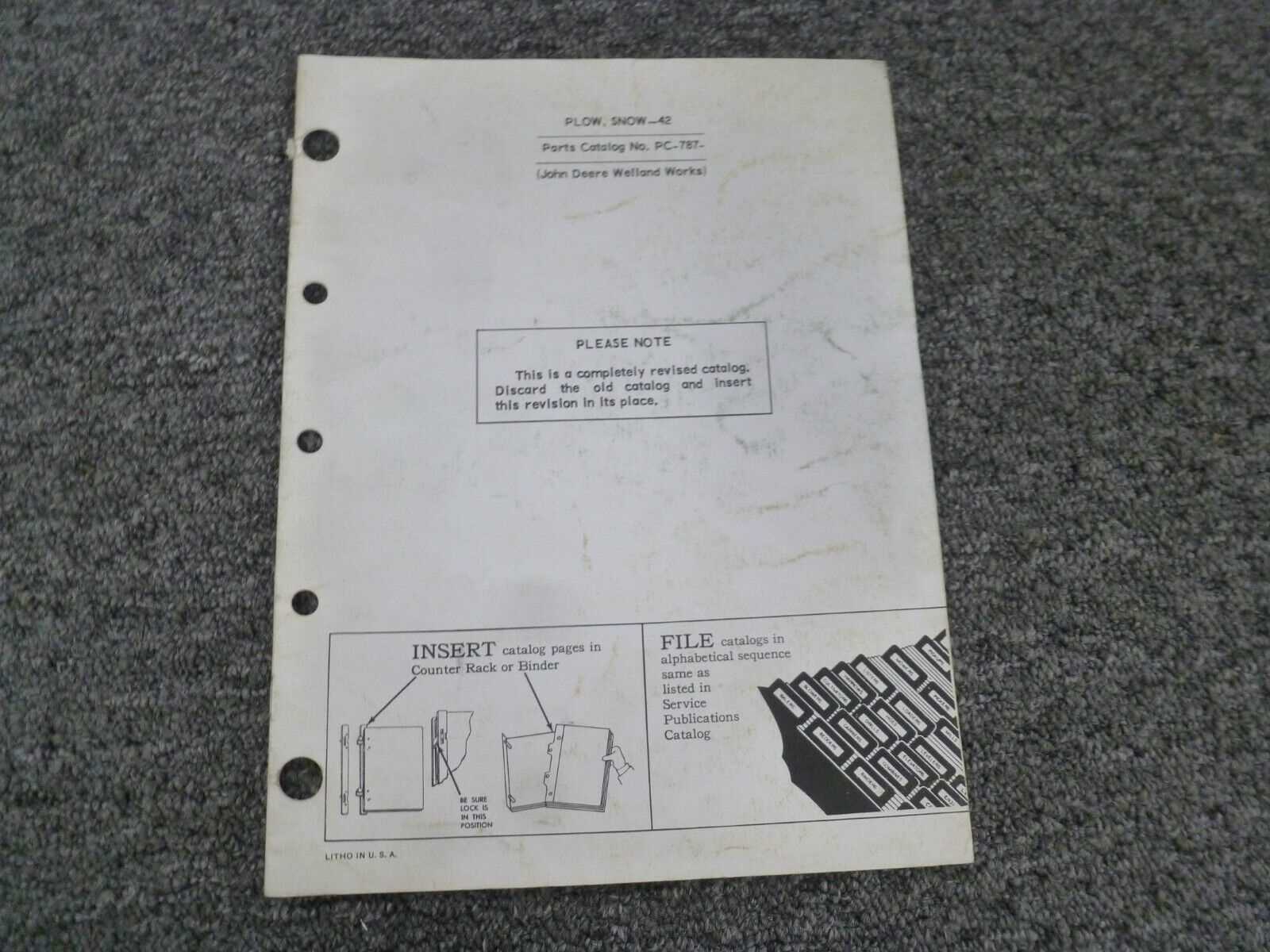

How to Read the Parts Diagram

Understanding how to interpret a reference guide is crucial for anyone working with complex machinery. These visual aids provide a clear layout of all the essential elements within the system, allowing users to quickly locate specific components and understand their relationships to one another. Mastering this skill ensures that you can make informed decisions when replacing or repairing parts.

Identifying Symbols and Labels

Each component is typically represented by a symbol or image, accompanied by a label that provides further information. These labels often include part numbers, descriptions, and sometimes even specifications. Recognizing these symbols is the first step to efficiently navigating through the guide and finding the exact pieces you need.

Interpreting Component Connections

In addition to the individual components, understanding how they connect and interact with each other is essential. Lines, arrows, and other visual indicators are used to represent the relationships between different parts. Knowing how these connections work helps ensure that the system functions correctly when assembling or disassembling it for maintenance.