When maintaining or repairing your machinery, it’s essential to have a clear understanding of its internal components. Whether you’re troubleshooting issues or performing regular upkeep, identifying and knowing how each piece fits together can save both time and effort. Proper knowledge of the system allows you to address problems effectively and avoid unnecessary replacements.

Exploring the inner workings of your machine is the first step toward ensuring smooth operation and longevity. An accurate visual representation of all elements involved helps you pinpoint specific areas in need of attention. With a detailed guide, understanding the assembly and functionality of various elements becomes much more manageable.

Familiarity with the most common issues and knowing which components are prone to wear can further help you in making informed decisions. With the right information, you’ll be able to maintain your equipment in peak condition, ensuring reliable performance throughout its use.

Understanding John Deere Snowblower Components

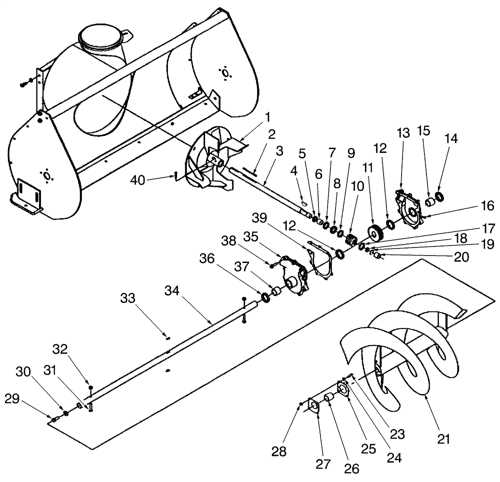

Knowing the individual elements of your machine is crucial for effective operation and maintenance. Each component plays a specific role in the overall function, and understanding how they interact ensures smoother performance. Whether you’re performing repairs or simply conducting routine inspections, it’s important to recognize how the various pieces work together.

Key components, such as the intake and discharge mechanisms, the drive system, and the auger, are essential for the movement of snow and proper machine functionality. Familiarizing yourself with these parts helps identify potential issues before they escalate into major problems. It also allows you to pinpoint specific areas for maintenance or replacement when necessary.

Regular upkeep can prevent premature wear and extend the life of the machine. Knowing the function of each element, from the engine components to the chute, allows for efficient troubleshooting and ensures that your equipment stays in top condition throughout its use.

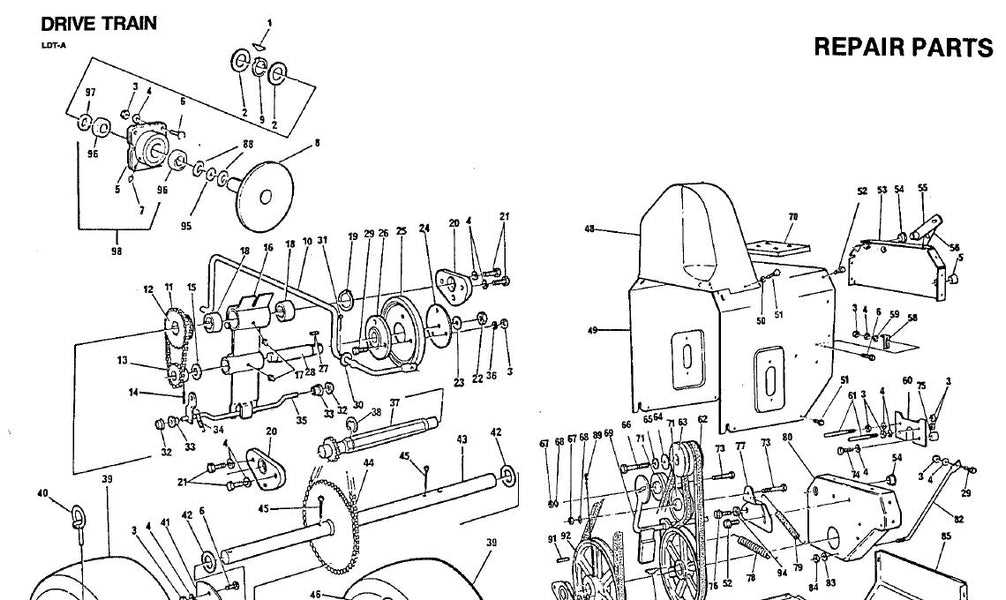

How to Read a Snowblower Parts Diagram

Understanding how to interpret a visual representation of your machine’s components is an essential skill for anyone who performs repairs or maintenance. These guides provide a clear layout of the system, showing how parts fit together and interact. Once you are familiar with the structure, identifying faulty components or areas in need of service becomes much easier.

Key Elements of the Guide

A well-organized illustration will label each element of the machinery clearly. Look for the following markers to ensure you can navigate the guide effectively:

- Labels: Each part should have a corresponding number or name, helping you to identify them easily.

- Connections: Arrows or lines often indicate how the pieces are connected or interact with each other.

- Part Numbers: These can be crucial for ordering replacement parts if needed.

Step-by-Step Approach to Reading

To read these visuals effectively, follow this approach:

- Start by identifying the larger, core components such as the engine or drive system.

- Move on to the smaller pieces that connect to these larger parts, such as belts or levers.

- Cross-reference part numbers with the manual or online resources for detailed information on each element.

By mastering this method, you’ll be able to troubleshoot and maintain your machine with confidence, ensuring optimal performance for longer periods.

Common Issues and Parts Replacement Tips

Every machine can experience wear and tear over time, especially after frequent use in harsh conditions. Recognizing the most common issues early on can save you time and prevent further damage. Regularly inspecting and replacing worn-out elements ensures the equipment continues to perform efficiently.

One common issue is a clogged intake or discharge chute, which can occur due to heavy snowfall or debris buildup. If the flow of material is obstructed, performance is significantly reduced. To fix this, check the chute for blockages and clean it thoroughly. Ensure that all moving components are free of debris.

Another frequent problem involves the drive system, where belts or cables may lose tension or become worn. If the machine starts to lose power or fails to move, inspect the drive mechanism. Replace any worn belts or adjust tension to restore proper functionality.

When it comes to replacing components, always refer to the manufacturer’s specifications for compatibility and correct installation. Keep a list of recommended replacement parts to streamline the process. Using genuine parts ensures optimal performance and reduces the risk of malfunction.

Maintaining your machine by addressing these common issues and replacing faulty components in a timely manner will help prolong its lifespan and keep it running smoothly.