For any machinery, knowing its internal structure and individual elements is essential for maintenance and repairs. A detailed guide to understanding the different components of a lawn mower can significantly enhance the user experience and prolong its lifespan. This section provides an overview of the key parts and how to identify and work with them efficiently.

Accurate knowledge of each component is crucial when diagnosing issues or performing repairs. Understanding where each piece fits and how it contributes to the overall functioning of the equipment can save time and prevent unnecessary replacements.

Learning the correct layout of a lawn mower’s assembly helps ensure proper usage and troubleshooting. With the right information, even small issues can be addressed without hassle, allowing the machine to operate smoothly and effectively for years to come.

Understanding the John Deere TRS27 Parts

Having a comprehensive understanding of the internal components of your equipment is vital for its longevity and optimal performance. Every machine consists of a variety of elements, each playing a unique role in ensuring smooth operation. A well-informed user can identify issues early and resolve them before they cause major problems.

Each element is designed with specific functionality in mind, and recognizing these components can help in both routine maintenance and troubleshooting. Knowing how each part interacts with others ensures that you can spot and address potential malfunctions promptly.

Whether you’re performing routine checks or replacing worn-out components, it’s essential to have a clear understanding of the machine’s layout and how each part contributes to the overall performance. This knowledge enables more efficient care, ensuring that your equipment stays in top condition for longer periods.

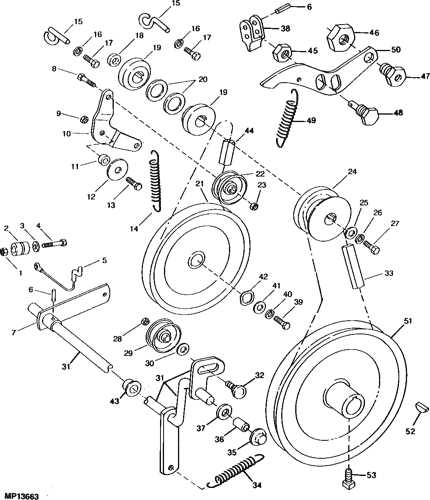

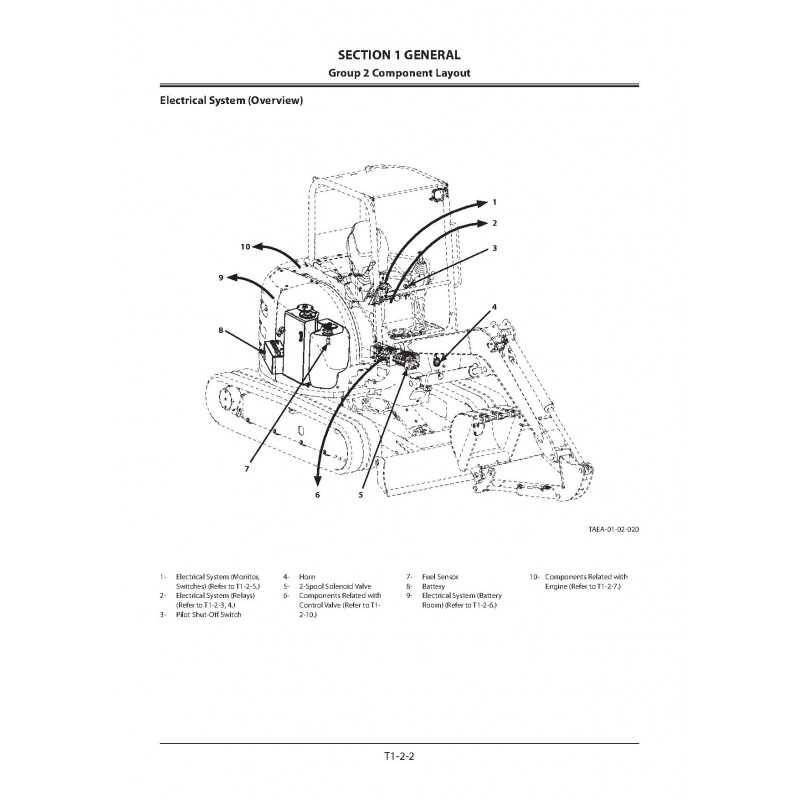

How to Read the Parts Diagram

Understanding how to read a detailed layout of your equipment’s components is crucial for effective maintenance and repairs. These visual representations offer a clear view of how various parts are connected and function together. By interpreting this layout correctly, you can more easily identify specific elements and troubleshoot issues.

Identifying Key Components

To begin, focus on the primary parts displayed in the layout. Each section of the visual guide typically corresponds to a particular part of the machinery, with clear labels and annotations. Understanding these markings allows you to quickly identify what each part is and where it fits into the overall structure.

Understanding Connections and Relationships

The layout not only shows individual parts but also how they are linked. These connections are often represented with lines or arrows, indicating how energy or power flows between the components. Recognizing these relationships is essential for diagnosing problems or performing repairs, as it shows how a failure in one part might affect others.

Common Repairs and Replacements

Over time, machinery may experience wear and tear that requires repairs or replacements. Addressing common issues promptly can prevent more serious problems and extend the lifespan of the equipment. Understanding which components are most likely to need attention allows for efficient maintenance and reduces downtime.

Worn-out Belts and Cables

One of the most frequent repairs involves replacing worn-out belts or cables. These parts are subjected to constant friction and stress, making them prone to damage. Regular inspection can help identify any signs of wear before they break, avoiding more costly repairs later.

Fuel and Air Filter Replacements

Another common replacement task involves the fuel and air filters. Over time, these filters can become clogged with debris, reducing the efficiency of the engine. Replacing them at regular intervals ensures optimal performance and helps prevent engine strain.