For any farmer or technician, understanding the machinery that powers agricultural operations is crucial for maintenance and repair. Complex machines consist of various components that must work together seamlessly to ensure efficient performance. Knowing each element’s role and how to replace or repair it can save time and prevent costly breakdowns.

In this guide, we will break down the essential components of a popular farming machine, focusing on how to interpret its detailed schematic. With clear explanations and useful tips, even beginners can grasp how to identify key parts and make informed decisions when servicing their equipment.

Maintaining optimal functionality requires familiarity with every piece of the system. This article will provide insights into recognizing, replacing, and troubleshooting the most important sections, ensuring smooth operation of the machinery in the long run.

Understanding John Deere Van Brunt Drills

A crucial aspect of modern agriculture is the ability to efficiently plant crops with precision. Machines designed for this task play an essential role in ensuring the seeds are planted at the correct depth and spacing. These machines are engineered to handle different types of terrain and soil conditions, making them versatile tools for a variety of farming operations.

Over the years, advancements in machinery technology have led to the development of sophisticated systems that incorporate various mechanisms. These mechanisms include seed meters, furrow openers, and row units, all of which work together to ensure the best planting results. Farmers who understand the functionality of each component can optimize their equipment and extend its lifespan, ultimately improving the efficiency of their operations.

Key Components of the Grain Drill

Understanding the main elements of a planting machine is vital for ensuring it operates smoothly and effectively. Each component has a specific function, contributing to the overall precision of the planting process. When every part is working in harmony, the machine can efficiently place seeds in the soil with the right spacing and depth, maximizing crop yields.

Seed Delivery System

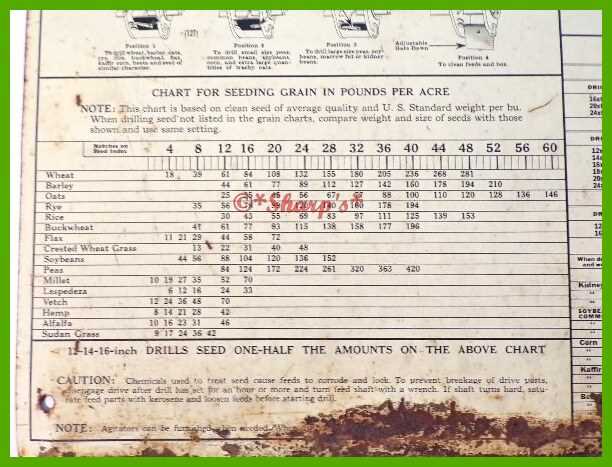

The seed delivery system is crucial for ensuring that the correct number of seeds is placed in each row at the right interval. This mechanism typically includes seed metering devices that regulate the flow of seeds from the hopper to the furrow openers. A reliable delivery system contributes to uniform planting and helps in minimizing seed waste.

Furrow Openers and Seedbed Preparation

Furrow openers are responsible for creating the space in the soil where the seeds are placed. These components come in various shapes and sizes, designed to handle different soil types and conditions. Properly functioning furrow openers ensure the seeds are planted at the correct depth and provide the ideal seed-to-soil contact for optimal germination.

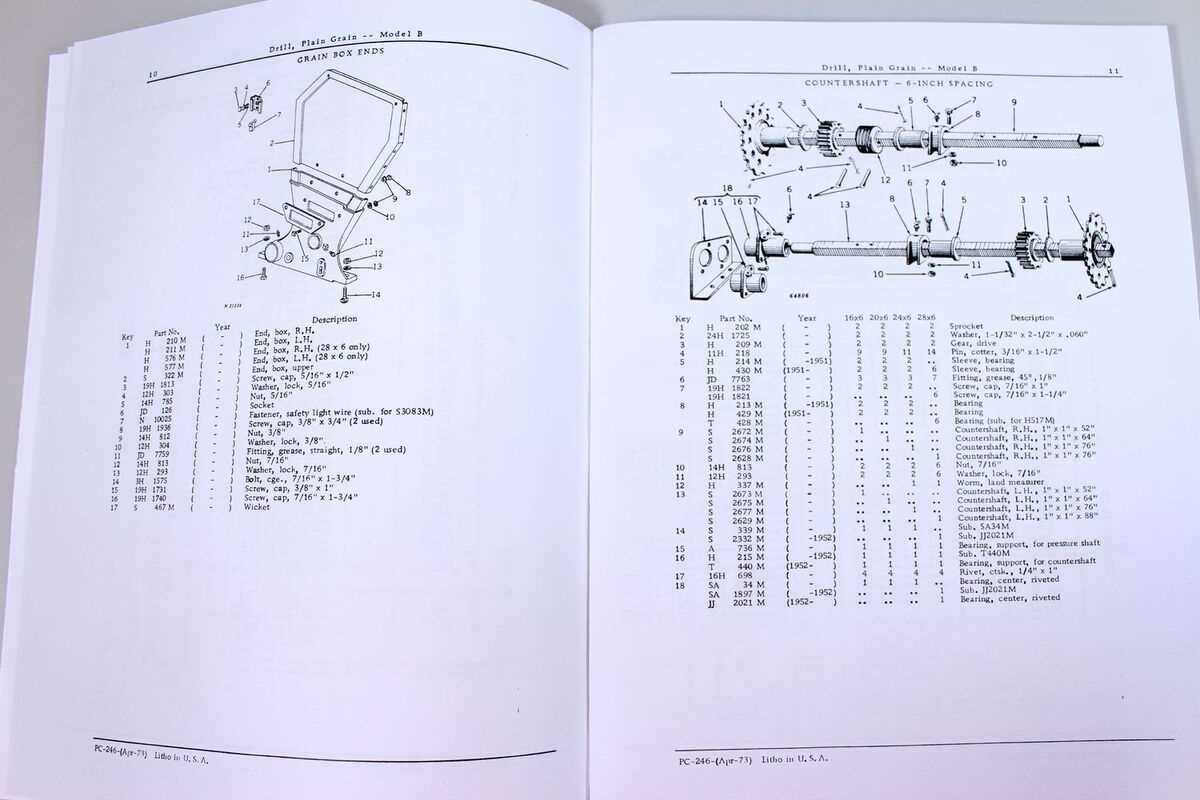

How to Read the Parts Diagram

Understanding the layout of a machine’s components is essential for successful maintenance and repair. A detailed schematic provides a visual representation of all the key elements, helping users identify parts, their connections, and their functions. By interpreting this guide accurately, one can easily locate where specific components fit and how they interact with others within the system.

Typically, these diagrams are organized in a way that groups related sections together, allowing for an easier understanding of the machine’s overall structure. Pay attention to numbers, symbols, and lines that indicate connections or movement paths. Labels and part names are essential for quick identification and are often linked to part numbers for easy reference when ordering replacements.

When interpreting the schematic, start by locating the major sections such as the frame or seed distribution system, then work your way through to smaller details. This methodical approach helps ensure no components are overlooked and assists in effective troubleshooting and part replacement.