When maintaining and repairing outdoor machinery, understanding the internal structure and functionality of each component is crucial for efficient operation. Properly identifying the various elements that make up the system allows for informed decision-making when it comes to troubleshooting, upgrading, or performing regular maintenance.

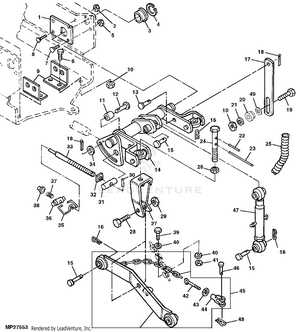

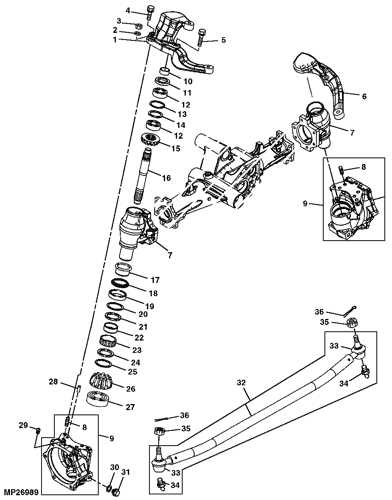

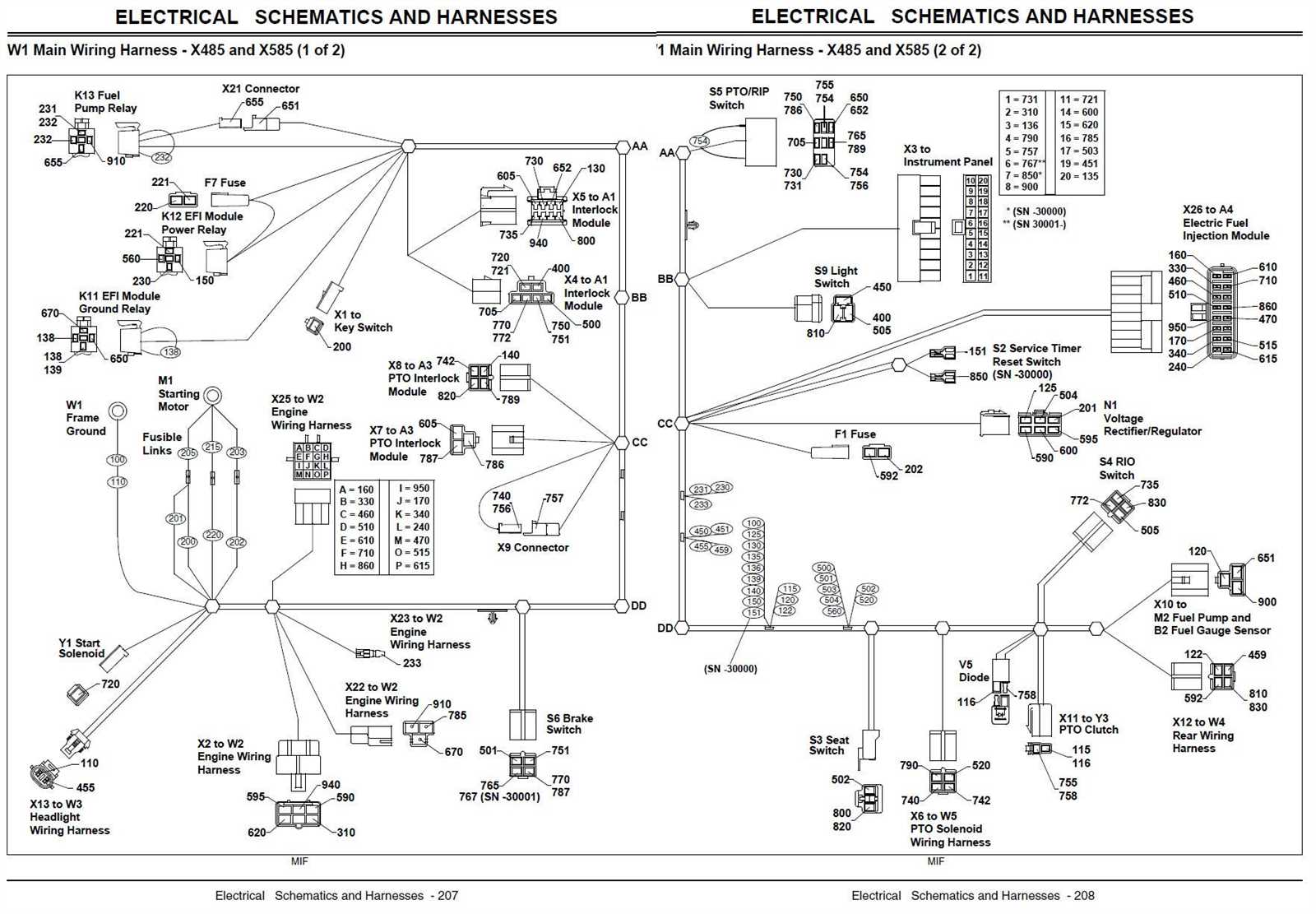

Diagrams and detailed breakdowns of a machine’s interior components offer valuable insight into how everything works together. By studying these, users can gain a deeper understanding of the connections between individual parts, ensuring that any issues are quickly identified and addressed.

Having access to clear visual representations of the equipment’s framework helps owners manage repairs independently, saving time and money. Additionally, such diagrams provide a reference point for replacement parts, ensuring compatibility and efficiency in repairs.

Understanding the John Deere X585 Components

When it comes to machinery, understanding the intricate network of components is essential for optimal performance. Every piece plays a specific role, working in harmony to ensure smooth operation. By familiarizing oneself with these elements, users can maintain, repair, and optimize their equipment with greater ease and accuracy.

For outdoor equipment, key components include the engine, transmission, and steering system. Each section is designed to serve a particular function, contributing to the overall effectiveness of the machine. Regular inspection of these individual components allows users to identify potential issues before they become major problems.

- Engine: Powers the entire system, ensuring movement and function.

- Transmission: Transmits power from the engine to the wheels, controlling speed and movement.

- Steering Mechanism: Directs the machine, enabling precise control during operation.

- Electrical System: Powers critical elements such as lights, sensors, and controls.

- Hydraulic System: Controls various functions, including lifting and adjusting attachments.

Recognizing how each of these systems interacts provides a clear understanding of how to troubleshoot, replace parts, or upgrade specific components. This knowledge also facilitates smoother maintenance processes, allowing users to extend the lifespan of their equipment and avoid costly repairs.

Key Parts for Efficient Operation

For optimal performance of any machinery, certain components are essential for smooth and reliable operation. These crucial elements are responsible for transferring power, controlling movement, and ensuring all systems work together seamlessly. Proper maintenance and understanding of these key parts can significantly enhance the efficiency and longevity of the equipment.

Among the most critical elements are the engine, transmission, and power delivery systems. Each plays a vital role in ensuring the machinery runs at its best, with minimal interruptions or failures. Regular inspection and care of these components help prevent unnecessary wear and improve the overall performance of the machine.

The following key components are central to maintaining efficient operation:

- Engine: The heart of the machine, providing the power needed for movement and operation of all systems.

- Transmission: Transfers power from the engine to the wheels, controlling speed and responsiveness.

- Powertrain: Includes all elements responsible for moving the machine, ensuring smooth and consistent movement.

- Steering System: Allows for precise control and maneuverability, essential for accurate navigation.

- Electrical System: Powers controls, sensors, and lights, ensuring proper functionality of key features.

Maintaining these essential components will help ensure a long lifespan for the equipment while providing reliable performance for every task. Regular checks and replacements are necessary to avoid costly repairs and keep everything running smoothly.

How to Maintain John Deere X585 Parts

Regular upkeep of machinery components is essential to ensure optimal functionality and avoid unexpected breakdowns. By focusing on proactive maintenance, users can extend the lifespan of their equipment and minimize costly repairs. Proper care and routine checks are crucial to maintaining smooth operation, enhancing performance, and avoiding wear over time.

Routine Inspection and Cleaning

One of the most effective ways to keep the equipment running smoothly is through regular inspection and cleaning. This involves checking for any signs of wear, leaks, or loose connections. Ensuring all moving parts are clean from dirt and debris also prevents buildup that could interfere with performance.

- Clean air filters regularly to maintain engine efficiency.

- Inspect belts for signs of damage or wear and replace them as needed.

- Check fluid levels for the engine and hydraulic system to ensure proper function.

Lubrication and Part Replacement

Proper lubrication is key to preventing friction between moving parts. Applying the right type of lubricant to critical areas reduces wear and ensures smoother operation. Additionally, replacing worn or damaged components before they fail helps maintain performance and avoid further damage to the machinery.

- Lubricate joints and bearings frequently to prevent rust and corrosion.

- Replace damaged seals to maintain fluid levels and prevent leaks.

By following these maintenance steps, users can ensure the longevity and efficiency of their equipment, allowing it to function at its best throughout its service life.

Maintenance Tips for Longevity

To ensure the long-term reliability and performance of your equipment, consistent maintenance is essential. By following a few key practices, you can significantly extend the lifespan of critical components and avoid unexpected failures. Regular care prevents minor issues from becoming major problems, ensuring smooth operation and avoiding costly repairs.

Regular inspections and keeping an eye on wear and tear are crucial steps in the upkeep process. Addressing small issues early can prevent them from escalating, saving both time and money in the long run. Additionally, keeping all systems clean and properly lubricated minimizes friction and prevents unnecessary damage.

- Check fluid levels regularly, ensuring that engine oil, transmission fluid, and hydraulic fluids are topped off.

- Inspect belts and hoses for signs of wear, cracks, or leaks and replace them as necessary.

- Lubricate moving parts to reduce friction and extend the life of critical components.

- Clean filters to ensure that airflow and fluid flow remain optimal, improving efficiency and preventing blockages.

By following these guidelines, your machinery will continue to perform at its peak, providing reliable service for years to come. Regular maintenance not only boosts efficiency but also helps preserve the value of the equipment over time.

Identifying Common Issues in X585

Identifying potential problems early is vital for maintaining equipment performance and minimizing downtime. While most machines are built to last, certain issues can arise over time due to regular use or external factors. Recognizing these issues early can prevent further damage and ensure the equipment continues to operate at its best.

Common issues often stem from specific areas such as the engine, transmission, or electrical systems. Problems can range from minor malfunctions to more severe failures, but with proper knowledge, users can quickly address them before they escalate. Regular inspections and awareness of typical symptoms are key to early detection.

| Issue | Symptoms | Possible Causes | Solution |

|---|---|---|---|

| Engine Stalling | Sudden power loss, rough idling | Dirty fuel filter, faulty spark plugs | Replace the fuel filter, clean or replace spark plugs |

| Transmission Slipping | Inability to change gears smoothly | Low fluid levels, worn transmission belts | Check and top off fluid levels, replace worn belts |

| Weak Steering | Difficulty in maneuvering, stiff steering wheel | Low hydraulic fluid, worn steering components | Top up hydraulic fluid, inspect and replace worn parts |

| Electrical Issues | Lights not working, failure to start | Loose connections, dead battery | Tighten connections, replace battery if necessary |

By being vigilant and addressing these common issues promptly, you can significantly extend the lifespan of the equipment and avoid unexpected malfunctions that could interfere with its daily operation.