Effective maintenance of lawn mowers requires a clear understanding of their structure and components. Knowing how each part fits together is essential for proper upkeep and troubleshooting. This guide will help you navigate through the complex system of mower parts, making it easier to identify and replace components when necessary.

By familiarizing yourself with the detailed breakdown of the mower’s system, you’ll be better equipped to perform regular maintenance and ensure optimal performance. Whether it’s for routine check-ups or during a repair session, having a reference for each part can save time and effort.

Accurate assembly knowledge is crucial not only for repairs but also for maximizing the mower’s longevity. Regular inspections and replacements can prevent malfunctions and enhance overall efficiency. Understanding how the machine operates from the inside out can provide valuable insights for more advanced tasks as well.

Understanding Lawn Mower Components

Every lawn mower is a combination of numerous individual elements that work together to ensure smooth operation. Knowing how these parts interact with one another is essential for both basic maintenance and troubleshooting. From the engine to the cutting system, understanding each component’s role will help in keeping the machine in peak condition.

Key Elements of the Mower System

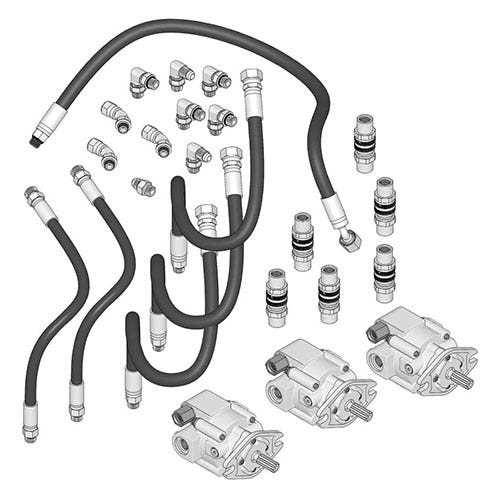

At the heart of any mower is the engine, which drives the blades and powers the other components. Alongside the engine, the cutting mechanism and drive system are the most critical parts that contribute to efficiency. The transmission system ensures the mower operates at the correct speed, while the fuel system guarantees proper engine function over time. Each part needs to be well-maintained to avoid unexpected breakdowns during operation.

Importance of Regular Maintenance

Maintenance is vital to ensuring that all components work as intended. Regular checks on key systems, such as the engine, blades, and drive mechanism, can prevent major failures. Replacing worn-out elements in a timely manner helps extend the machine’s lifespan. Understanding how each part functions allows you to spot potential issues early, saving both time and money on repairs.

How to Read the Assembly Breakdown

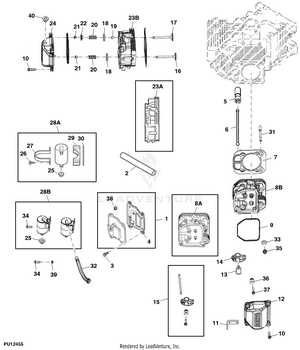

Understanding the visual representation of a machine’s components can significantly improve your ability to identify, troubleshoot, and replace individual parts. A detailed illustration provides a clear view of how each part fits into the system, helping you follow the structure and order of assembly. Knowing how to interpret these diagrams is crucial for effective repairs and maintenance.

Familiarizing with the Layout

The first step in reading the breakdown is to get familiar with its layout. Typically, parts are organized in a way that shows their relation to one another. For example, the central components, like the engine or cutting system, are usually highlighted, with additional elements branching out from these key systems. Labels and numbers are used to identify each component, making it easy to find them in a parts catalog for replacement.

Understanding the Symbols and Notations

Each illustration may include symbols or notations to indicate specific types of components, such as fasteners or connectors. Some diagrams may also have arrows or lines showing the flow of power or mechanical movement. Being able to decode these symbols is essential for understanding how the machine operates and which components are interconnected. Properly reading these diagrams ensures that the right parts are accessed and replaced during repairs.

Common Maintenance Tips for Mowers

Proper maintenance is key to extending the lifespan and enhancing the performance of any lawn equipment. Regular upkeep ensures that the machine operates efficiently, reduces the risk of breakdowns, and saves on costly repairs. By following a few simple maintenance practices, you can ensure smooth operation and avoid unnecessary disruptions during use.

Regularly Check the Engine and Fuel System

The engine is the heart of any mower, and keeping it in good condition is essential for optimal performance. Check the oil level and change it regularly to prevent overheating and wear. Additionally, inspect the fuel system for any leaks or blockages, as fuel quality can greatly affect engine performance. A clean fuel filter and properly maintained fuel lines can help prevent engine failure.

Maintain the Cutting Blades and Belts

The cutting blades and belts are some of the most vital components of a mower. Dull or damaged blades can cause uneven cuts and unnecessary strain on the engine. Sharpen or replace the blades when needed to ensure a clean, efficient cut. Also, check the belts for signs of wear or cracks and replace them if they appear damaged. Proper tension on the belts is crucial to ensure smooth power transmission.