Understanding the inner workings of your mower is crucial for its long-lasting performance and efficiency. Proper maintenance and timely repairs rely heavily on knowing the key elements that make up the machinery. Whether you’re a professional or a homeowner, familiarity with these components ensures smoother operation and fewer breakdowns.

Identifying each crucial element in the machine allows for quicker troubleshooting and effective repairs. By learning how to properly read the schematic, you can locate, replace, or maintain specific parts with ease, saving time and effort in the long run. Familiarizing yourself with these technical details not only enhances the user experience but also extends the equipment’s lifespan.

This guide will help you navigate through the essential components and their functions. Understanding how each piece fits together and works in harmony will enable you to keep your mower in top condition throughout its service life.

Understanding Key Components of the Mower

When operating complex machinery, it’s essential to understand how various elements work together to ensure smooth and efficient performance. Every machine is built from a series of interconnected systems, each with its own specific function. Recognizing the role of each part helps prevent issues and allows for better management of maintenance and repairs.

Knowing the main components of the mower and their respective duties provides a clear view of how the system operates. By understanding the function of each section, you can easily identify potential problems and perform precise replacements or adjustments when necessary. Familiarity with these essentials also improves overall operational efficiency and helps maintain peak performance throughout its lifecycle.

From the engine to the drive system, each key element contributes to the seamless operation of the equipment. Knowing how these components interact gives users confidence in troubleshooting and maintaining the machine properly.

How to Read the Mower Schematic

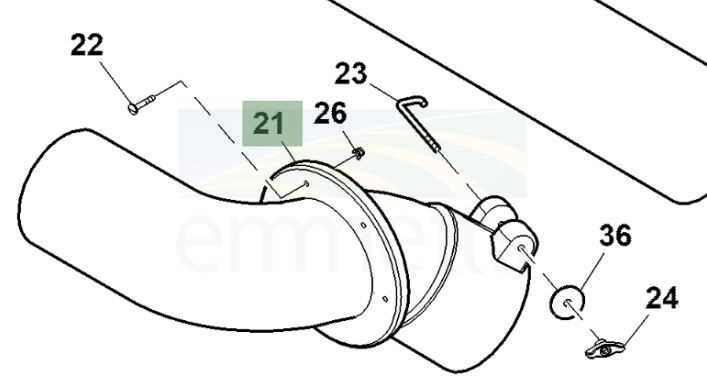

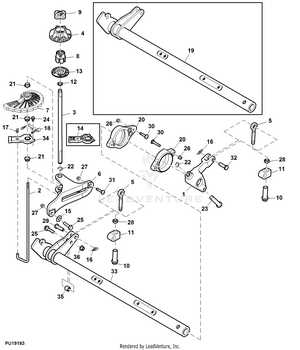

Interpreting technical illustrations is crucial when performing maintenance or repairs on machinery. These schematics provide a visual representation of the machine’s internal systems, showing how various elements are arranged and interact. Understanding how to read these visuals ensures that you can locate the correct components and identify potential issues without confusion.

Each symbol and label in the schematic represents a specific part or section of the equipment. By familiarizing yourself with these markings and their corresponding components, you can easily trace the flow of operations and pinpoint areas needing attention. Knowing the layout allows for efficient troubleshooting and ensures that every part is correctly installed or replaced.

Once you understand how the system is mapped out, you’ll be able to interpret these schematics with ease, making maintenance tasks more manageable and reducing downtime during repairs.

Importance of Regular Maintenance for Mower

Maintaining equipment regularly is essential for ensuring its optimal performance and extending its lifespan. Regular care helps identify and address minor issues before they become major problems, preventing costly repairs and unexpected downtime. By following a scheduled maintenance routine, users can ensure that all systems are functioning efficiently and safely.

Preventing Costly Repairs

Routine checks allow you to catch wear and tear early, preventing more expensive breakdowns in the future. Simple tasks like oil changes, filter replacements, and tightening loose parts can go a long way in preventing damage to crucial components. By staying proactive, you ensure that the machinery operates smoothly and avoids costly service bills.

Improving Efficiency and Safety

Consistent maintenance not only ensures that the mower runs at peak efficiency but also enhances safety. Properly maintained equipment is less likely to experience failures during use, reducing the risk of accidents or damage. Regular upkeep ensures that all systems, from the engine to the drive mechanism, are performing optimally, providing reliable results each time.