Maintaining your boat engine is crucial for ensuring smooth operation and longevity. Proper knowledge of its structure and individual components can help prevent unexpected failures and costly repairs. A clear understanding of how each part interacts with the others is essential for effective troubleshooting and maintenance.

By familiarizing yourself with the engine’s layout, you can quickly identify issues, perform routine checks, and replace worn-out elements. Having a detailed reference guide simplifies the repair process and helps you spot potential problems before they escalate.

In this guide, we’ll walk you through the essential parts of a small marine engine, focusing on their functions and how to recognize them for regular upkeep. Whether you’re a seasoned boater or a novice, knowing your engine’s setup will increase your confidence and improve overall performance.

Understanding the Johnson 9.9 Engine Layout

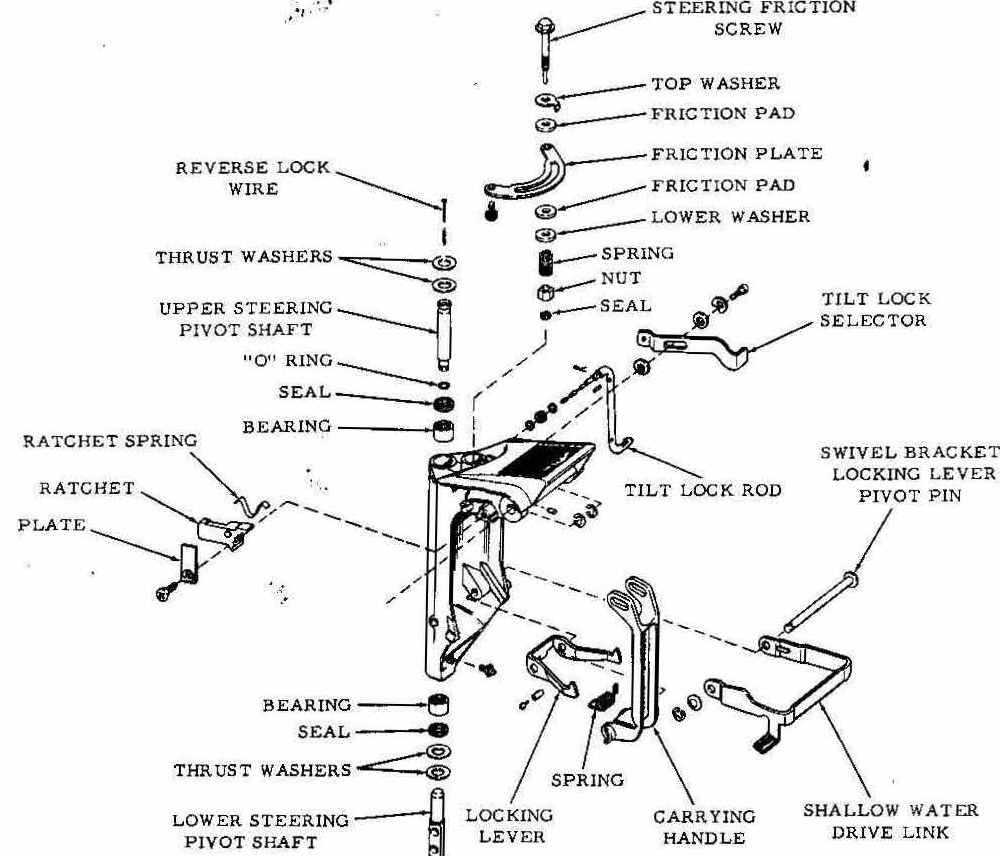

Familiarizing yourself with the layout of your boat’s engine is a fundamental step towards effective maintenance and repair. Each component serves a specific purpose, and understanding how they fit together allows for better troubleshooting and efficient upkeep. This section will guide you through the general structure of the engine, highlighting the key sections and their functions.

Key Sections of the Engine

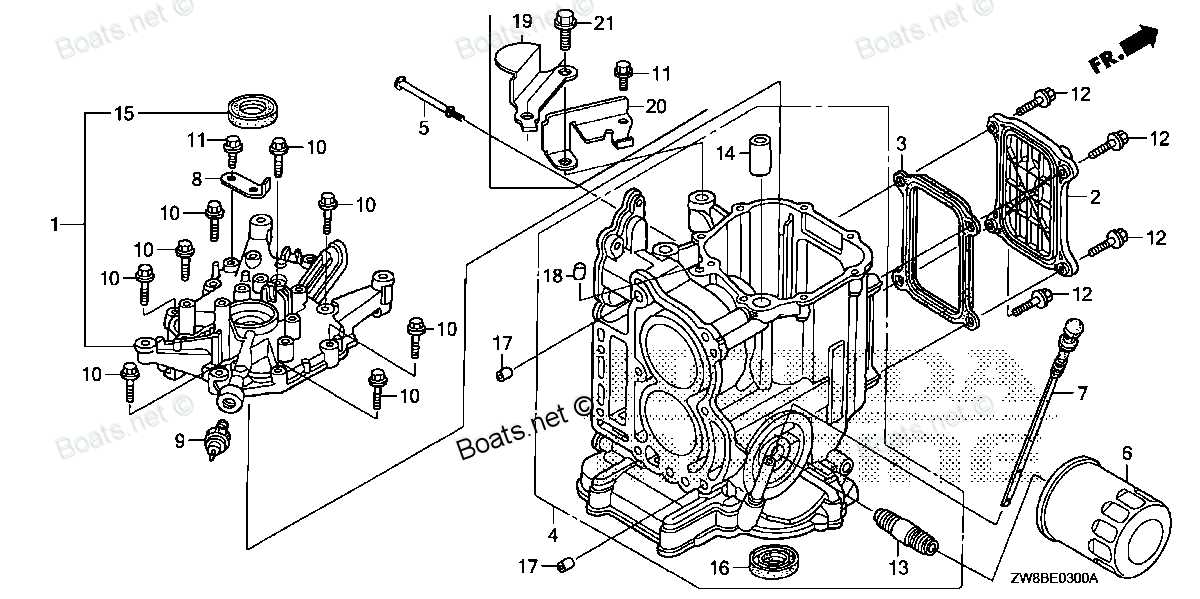

The engine is divided into several primary areas, each responsible for a different aspect of operation. The powerhead, for example, contains the crucial components such as the cylinder and piston. These are responsible for generating the engine’s power. Surrounding it, you will find parts like the carburetor and ignition system that ensure the combustion process runs smoothly.

Critical Systems for Optimal Performance

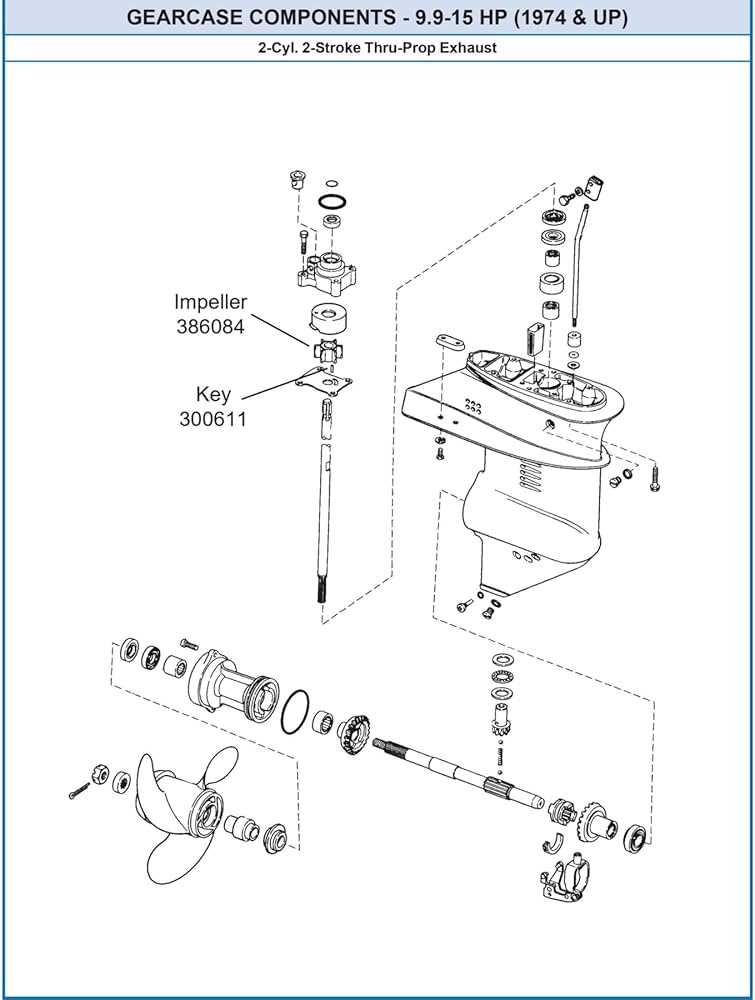

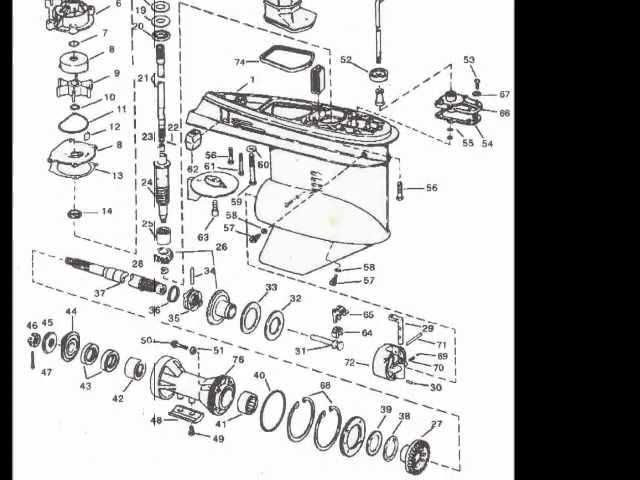

For the engine to function effectively, various systems must work together. The fuel system, cooling system, and exhaust system all play vital roles in maintaining the engine’s performance. The fuel system controls the delivery of gasoline to the engine, while the cooling system prevents overheating, and the exhaust system expels gases from combustion. Each of these systems requires regular checks to keep the engine in peak condition.

How to Identify Key Outboard Parts

Identifying the main components of your marine engine is essential for effective maintenance and repair. By understanding each part’s role, you can quickly detect issues and take necessary action to ensure smooth operation. This section will provide tips on how to spot the critical components and their functions.

Essential Components to Recognize

The engine’s functionality relies on several important elements, each contributing to its overall performance. Here are the key components you should familiarize yourself with:

- Powerhead: The core of the engine, where fuel combustion occurs.

- Carburetor: Regulates the mixture of air and fuel that enters the engine.

- Ignition system: Responsible for starting the engine by creating a spark.

- Fuel tank: Stores the fuel needed for engine operation.

- Cooling system: Prevents the engine from overheating by circulating coolant.

How to Spot Common Issues

Once you’ve identified the major components, it’s important to know how to spot common problems that may arise. Here are some common signs of malfunction:

- Powerhead issues: Reduced power or strange noises may indicate a problem with the combustion chamber or piston.

- Carburetor troubles: Difficulty starting or poor performance could mean the carburetor is clogged or misadjusted.

- Ignition system failure: A faulty ignition system may prevent the engine from starting or cause inconsistent performance.

Recognizing these signs early can help you avoid costly repairs and maintain optimal engine performance.

Common Issues with Johnson 9.9 Components

Like any mechanical system, a marine engine can encounter issues over time that affect its performance. Recognizing these problems early can prevent further damage and ensure the engine runs efficiently. This section highlights some of the most common problems that may arise with various components of your engine.

Fuel System Problems are often at the heart of engine difficulties. A clogged fuel filter or dirty carburetor can restrict fuel flow, leading to engine stalling or poor performance. In some cases, fuel can even become contaminated, affecting combustion and causing starting issues.

Overheating is another frequent problem, typically due to a malfunction in the cooling system. This may result from a clogged water pump or debris blocking the cooling passages. Overheating can cause significant engine damage if not addressed promptly.

Electrical Failures can also occur, especially in the ignition system. A faulty spark plug, ignition coil, or wiring issues can prevent the engine from starting or cause it to run erratically. These problems can often be diagnosed with a simple visual inspection and testing of electrical components.

Regular maintenance and early detection of these issues can extend the life of your engine and keep it running smoothly.