For efficient maintenance and repairs, having a clear understanding of machine components is crucial. Recognizing each element’s function and location helps in troubleshooting issues quickly and accurately. Whether you’re a professional mechanic or a DIY enthusiast, knowing the parts layout can save both time and effort when fixing or upgrading your equipment.

Recognizing and categorizing components is the first step in any repair process. With an accurate breakdown, you can easily identify the specific part that may be causing the problem. This knowledge ensures you have the right tools and replacements on hand, preventing unnecessary delays.

Once you identify the faulty or worn-out pieces, replacing or repairing them becomes a straightforward task. A good reference guide can significantly reduce mistakes, ensuring that each part fits correctly and functions as expected. This leads to improved performance and a longer lifespan for your machinery.

Understanding the Equipment Layout

For effective maintenance and troubleshooting, it is essential to have a clear understanding of the different components within your machinery. Knowing the layout helps to identify each piece’s function, ensuring that repairs or replacements are done accurately. A well-organized component guide provides clarity, helping users recognize the arrangement and importance of each part in the system.

How Components Are Organized

In most equipment, the components are arranged logically to facilitate ease of use and repair. Parts are often grouped based on their function, such as those related to mobility, power transmission, or control mechanisms. Understanding this organization allows for quicker identification of any part that may require attention or replacement.

Locating Specific Parts Quickly

By familiarizing yourself with the layout, you can efficiently locate any part within the assembly. This knowledge speeds up the diagnostic process and ensures that any necessary repairs or upgrades are carried out with minimal delay. A detailed visual reference can further simplify this task, providing a clear view of how each element fits into the overall structure.

How to Identify Equipment Components

Identifying individual components within machinery is an essential skill for effective repairs and maintenance. Knowing how to recognize each element’s function and position within the system can significantly reduce the time spent troubleshooting issues. A structured approach to component identification can streamline the repair process and ensure that the right part is addressed at the right time.

Familiarizing Yourself with the Layout

The first step in identifying components is to become familiar with the layout of the equipment. Each machine has a unique structure where parts are strategically placed based on their function. By studying the overall design, you can better understand how different elements work together. This foundational knowledge makes it easier to pinpoint the location of specific parts when needed.

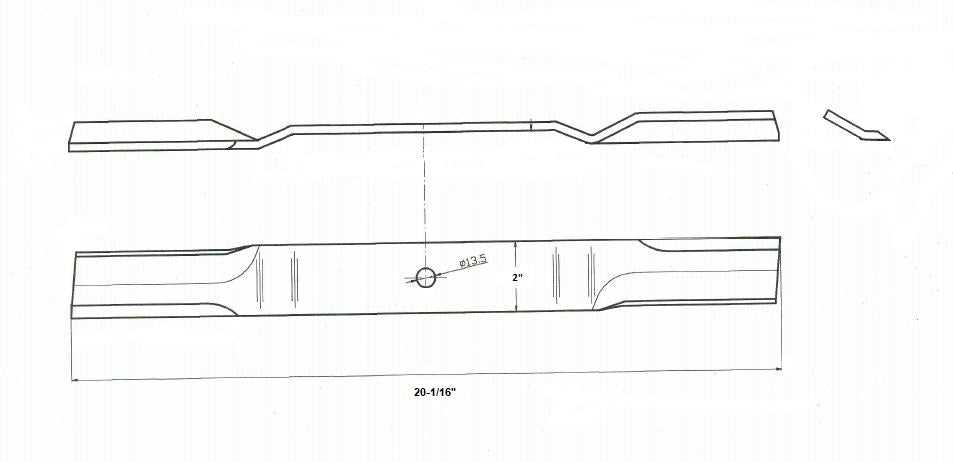

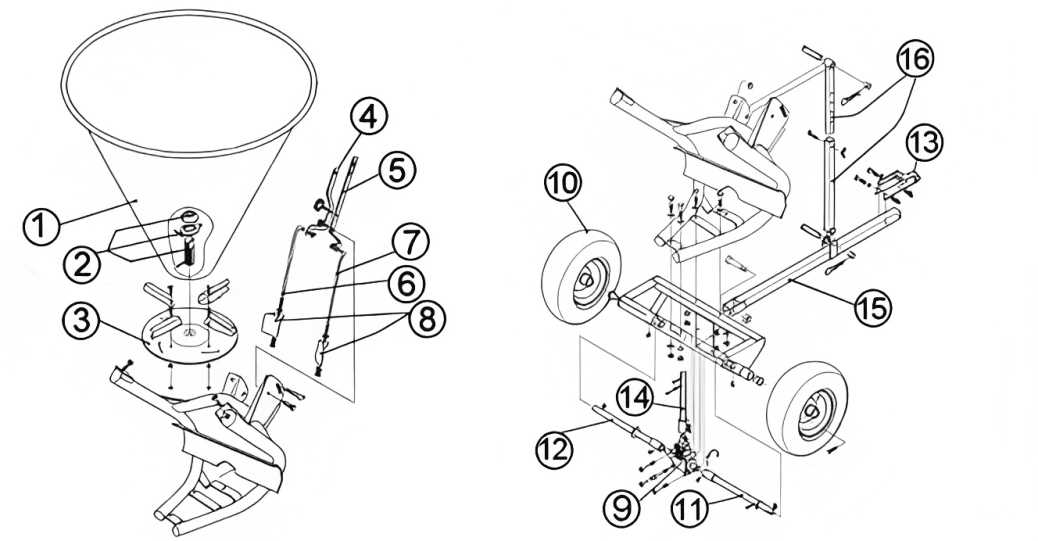

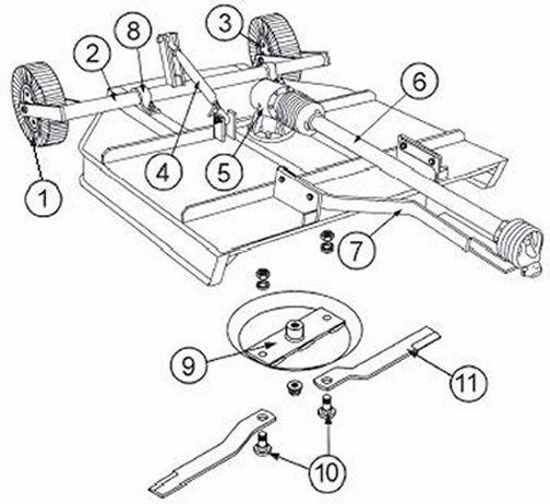

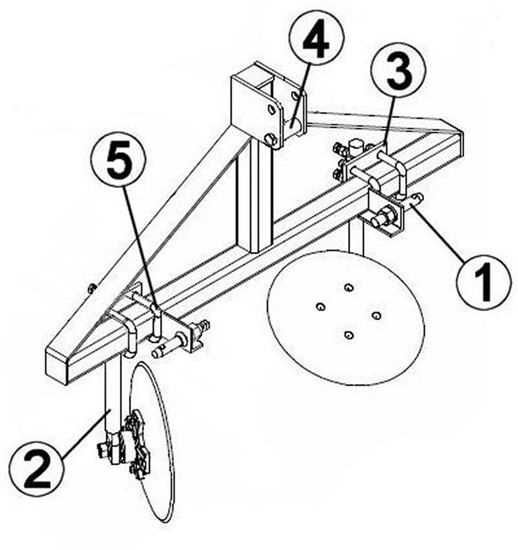

Using Visual References

Visual aids, such as diagrams or exploded views, can be extremely helpful in locating and identifying parts. These references provide a clear and detailed look at how each piece fits into the system, allowing for quicker identification. By cross-referencing the visuals with your equipment, you can easily spot any part that may need attention or replacement.

Repairing and Replacing Equipment Components

Repairing and replacing machinery components requires a clear understanding of the problem and proper procedures. Whether it’s fixing a malfunctioning element or upgrading an old part, the process can be straightforward if approached methodically. Knowing how to address specific issues can prevent unnecessary damage and extend the life of your equipment.

Steps for Effective Repairs

To begin with, it’s crucial to correctly diagnose the issue before attempting any repairs. Carefully examine the machinery and identify which part is causing the problem. Once identified, ensure that the correct tools and replacement parts are available. Always follow the manufacturer’s instructions to avoid improper handling that could lead to further damage.

Replacing Worn or Damaged Components

When replacing a faulty or worn-out component, it’s important to choose the correct replacement that matches the specifications of the original part. After removing the damaged piece, ensure the new part is securely installed and properly aligned with the surrounding elements. Testing the equipment after installation can confirm that everything is functioning correctly and safely.