Understanding the structure and functionality of farming machinery is crucial for ensuring long-term efficiency and durability. The equipment used for land management consists of various elements that work together to perform essential tasks. Knowledge of these components allows for better maintenance and problem-solving when issues arise.

In-depth knowledge of each piece helps to identify potential wear and tear, leading to timely repairs and replacements. For owners and operators, having a clear representation of how each part fits into the overall system is essential for maximizing performance.

Proper care and understanding of these devices not only extend their lifespan but also prevent unnecessary downtime during critical operations. By breaking down the machinery into its individual parts, users can gain a deeper appreciation for the inner workings and maintain smooth functionality over time.

Understanding the Agricultural Land Management Equipment

The machinery designed for land maintenance is essential for a variety of farming and gardening tasks. These tools are built to efficiently manage and clear large areas of land, handling dense vegetation and rough terrain. A deeper understanding of their construction helps operators ensure the longevity and functionality of the equipment, allowing it to perform at its best for years.

Key Elements of the Land Management Machine

The primary components of this agricultural tool work together to deliver consistent results. The frame provides the structure, while the rotating blades efficiently handle tough vegetation. Understanding the role each part plays within the system can help users troubleshoot any issues that may arise during operation.

Maintaining Optimal Performance

Regular maintenance is crucial to ensure the equipment remains in working order. Proper care involves not only checking the mechanical parts but also ensuring that each component is securely connected. Replacing worn-out parts promptly and lubricating moving elements can prevent serious damage and downtime.

Key Components of the Agricultural Equipment

The construction of land management machinery relies on several essential components that work in harmony to perform its tasks efficiently. Each part has a specific function, and understanding how they interact ensures the equipment operates smoothly and effectively. Knowing the individual components also helps users identify potential problems and keep the machine in peak condition.

Essential Structure and Mechanism

The main body of the machine provides stability and support for the rotating elements. These structural components, including the frame and housing, are designed to endure tough conditions and heavy use. The rotating blades or discs are responsible for the cutting action, efficiently clearing overgrown areas with minimal effort.

Moving Parts and Maintenance

Several moving elements work together to ensure the tool functions properly, including gears, shafts, and bearings. These parts enable smooth rotation and precise cutting. Regular maintenance of these moving parts, including lubrication and timely replacement of worn-out elements, is essential to prevent malfunctions and extend the life of the equipment.

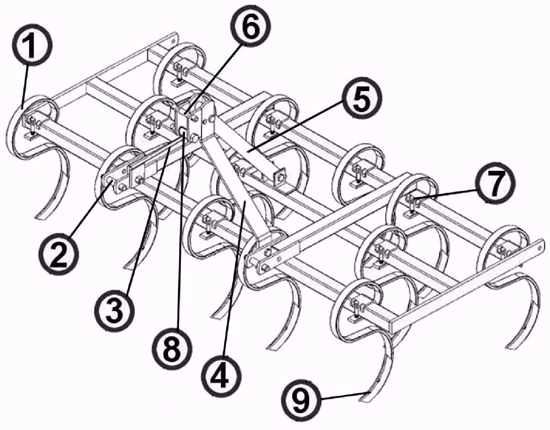

How to Use the Parts Diagram Effectively

Utilizing a detailed visual representation of a machine’s components is an invaluable tool for both troubleshooting and regular maintenance. Understanding how each part is positioned and connected within the system can make repairs or replacements more straightforward. By referencing the illustration, users can identify specific elements that need attention and avoid unnecessary disassembly.

Step-by-Step Guide for Troubleshooting

When issues arise, start by consulting the visual guide to locate the part that may be malfunctioning. Identify any worn or damaged sections, and verify their function within the system. This method ensures you only focus on the necessary areas, reducing the time spent on ineffective adjustments.

Effective Maintenance with Visual Aid

Regular upkeep becomes much simpler with a clear map of the machine’s construction. By following the diagram, you can systematically inspect each part, ensuring everything is functioning correctly and replacing any worn-out components before they cause more serious damage. This approach can save both time and money in the long run.