Efficient operation of farming machinery depends on the proper functioning of its various components. Understanding how each piece works together can help ensure smooth performance and easy troubleshooting when issues arise. This section will explore the essential elements that make up a typical agricultural machine, offering insight into their roles and importance.

Key Elements of Agricultural Machinery

Each farming machine is made up of several interconnected components, each designed to perform specific tasks. From the power source to the attachment mechanisms, these parts must work seamlessly to achieve desired results. It’s essential to identify each piece, understand its purpose, and know how it contributes to the machine’s overall performance.

Commonly Used Parts

- Drive Mechanisms: These include belts, shafts, and gears that transfer power to the different parts of the machine.

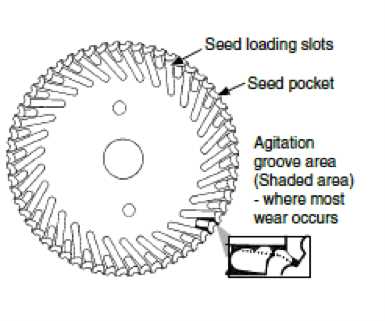

- Seeding Mechanisms: Designed to plant seeds at the correct depth and spacing for optimal growth.

- Row Units: These units are responsible for managing the soil and seed placement.

Typical Issues and Solutions

Familiarity with the machine’s design allows operators to identify and address issues quickly. Common problems include wear and tear, misalignment, or malfunctioning attachments. Regular maintenance and understanding of each part’s function can help prevent most operational issues.

Maintaining Your Equipment

Maintenance is crucial for extending the lifespan of agricultural machinery. Regular inspection and timely replacement of worn-out parts ensure continued high performance. It’s important to follow manufacturer guidelines for servicing and replacing key components to maintain machine efficiency.

Understanding Agricultural Equipment Components

Farming machinery relies on a combination of essential components working in unison to ensure efficient operation. Understanding the roles of each part and how they interact is crucial for smooth performance. This section will guide you through key components, how to interpret their layout, common issues, and the importance of regular maintenance for optimal function.

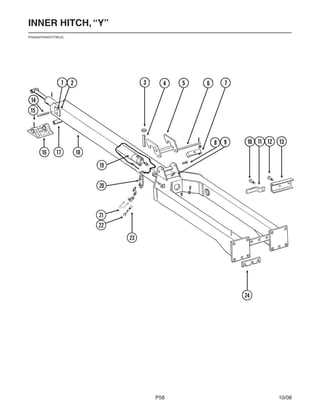

How to Interpret Machinery Layouts

To effectively maintain and troubleshoot your equipment, it is important to understand its layout. The assembly of components is often illustrated in detailed schematics that help operators identify each element’s role. By studying these illustrations, you can more easily locate any parts requiring attention or repair, making the process of maintaining your equipment much simpler.

Common Problems with Agricultural Components

While farming equipment is designed for durability, issues can still arise. Common problems include worn-out attachments, misalignments, or failure of drive systems. These issues can result in decreased performance and efficiency. Regularly reviewing your machine’s components and understanding potential points of failure can help minimize downtime and avoid costly repairs.

Caring for Equipment for Longevity

Proper maintenance is the key to ensuring the longevity of your machinery. Regular inspections, cleaning, and timely replacement of worn parts are necessary to maintain optimal performance. Following manufacturer guidelines and using high-quality replacements will ensure your equipment operates smoothly for years to come.