When working on heavy machinery, understanding how each part fits into the larger system is crucial. A clear representation of the different components and their relationships can simplify the repair process and ensure proper maintenance. This guide provides insights into how to read and use such illustrations for effective troubleshooting and upkeep of your equipment.

How to Interpret the Visual Guide

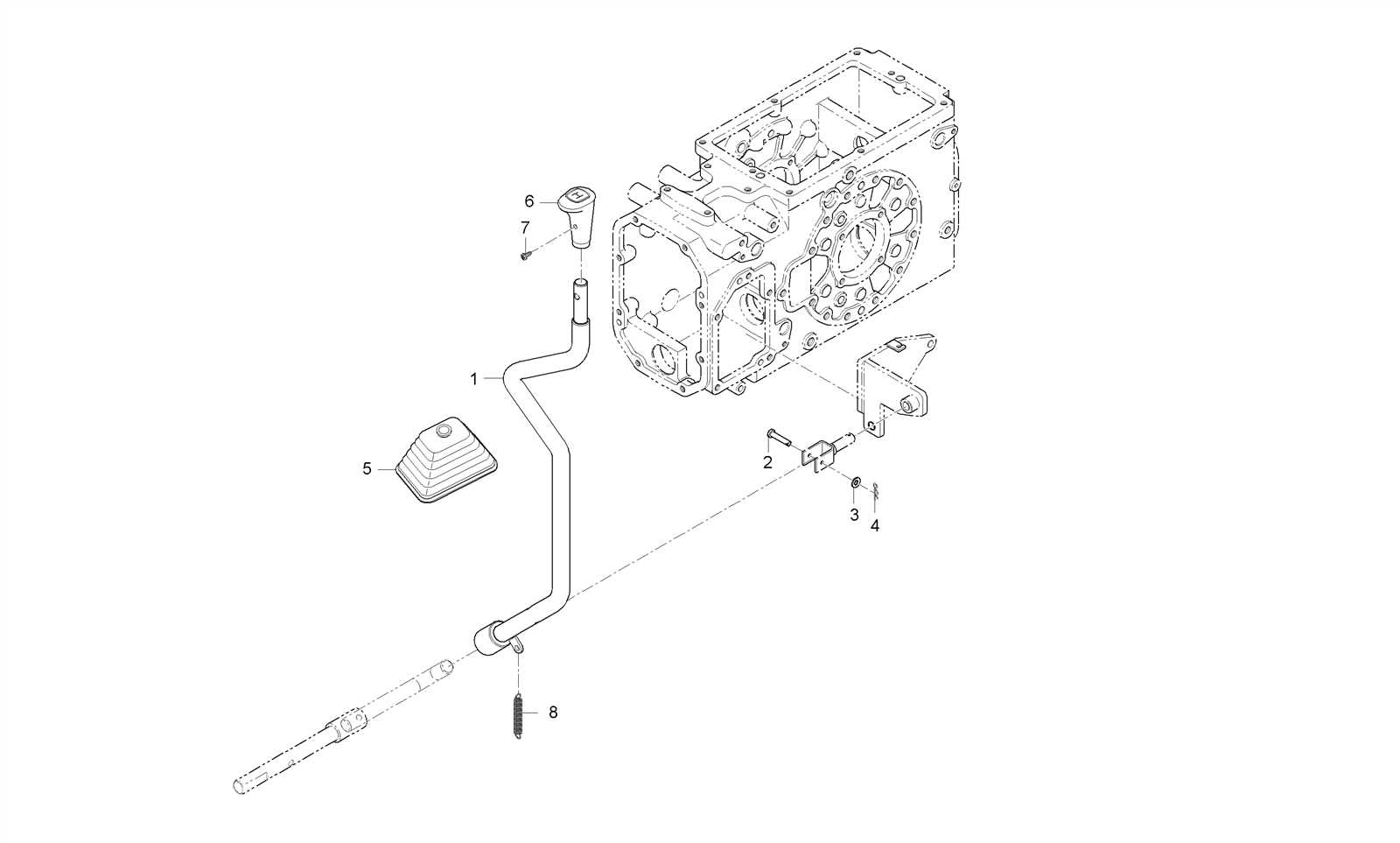

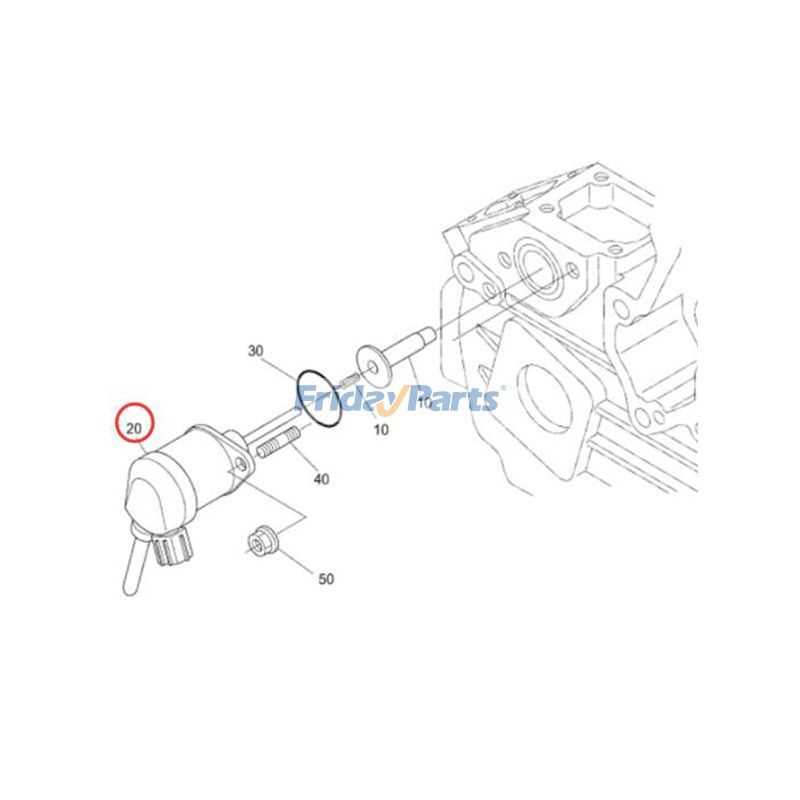

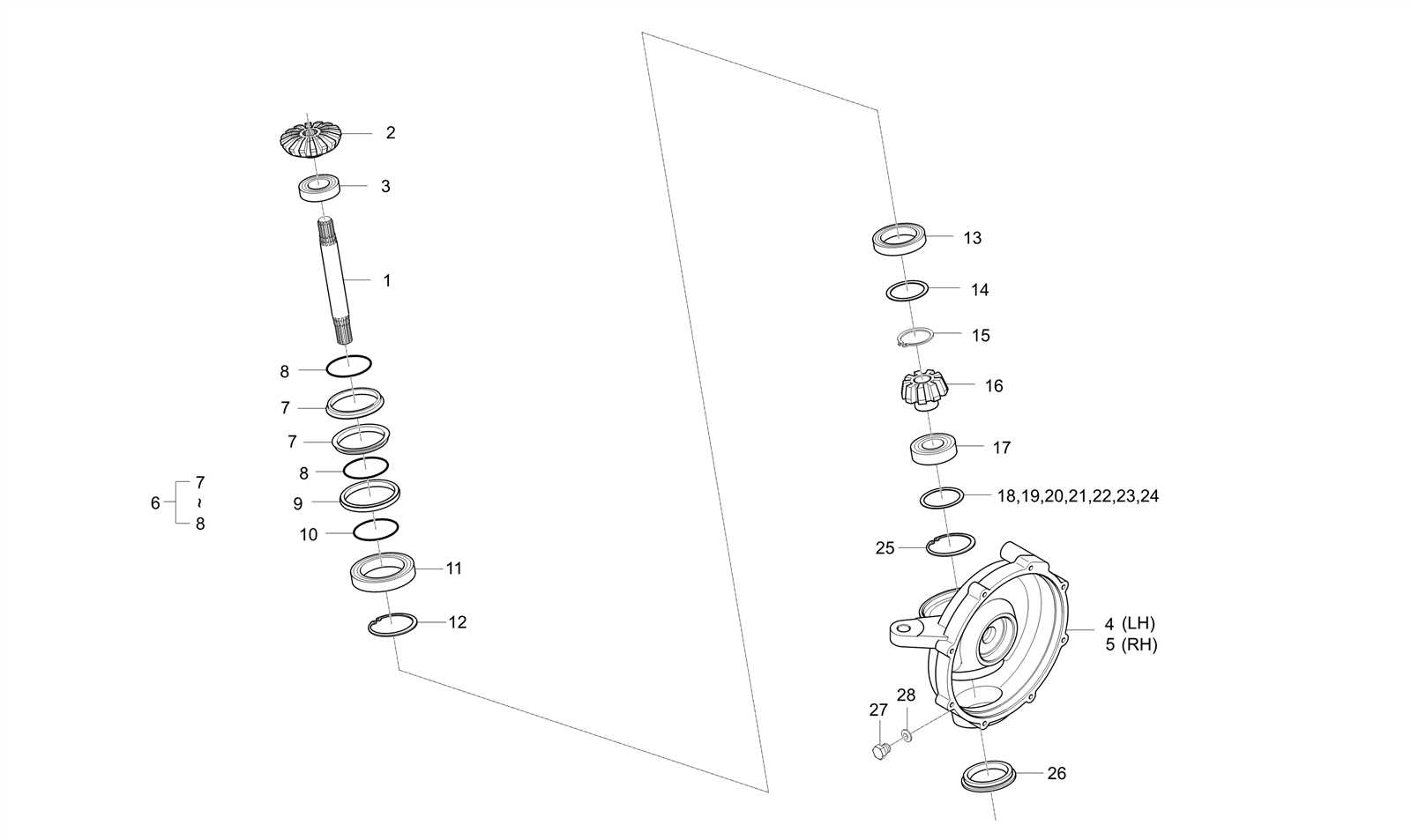

Visual guides serve as valuable resources for anyone looking to repair or maintain machinery. They break down complex systems into easily identifiable sections, making it easier to locate and address any issues. These guides often include numbered or labeled parts, showing their location within the machine and how they connect to each other. To make the most of these resources, you need to understand the key symbols and markings used, which can vary depending on the manufacturer.

Step-by-Step Breakdown

To successfully navigate the guide, follow these steps:

- Identify the Section: Start by locating the specific area of the machine you’re working on, such as the engine or transmission.

- Locate Key Components: Look for the most important parts that are critical for the repair or maintenance you’re performing.

- Match with Labels: Compare the numbers or letters on the guide to their corresponding parts to ensure accuracy.

- Understand the Connections: Pay attention to how components are linked, which can help in disassembly or reassembly.

Common Issues and Solutions

Many repairs can be tackled by first understanding how parts work together. Common issues such as engine failure, overheating, or mechanical breakdowns often trace back to one or more components that need attention. By using the guide, you can identify these parts more quickly and make informed decisions on what needs to be repaired or replaced.

Example of Troubleshooting

If your machinery isn’t starting, check the electrical system. Using the guide, identify the battery and starter components. By ensuring they are connected properly and free from damage, you can eliminate some of the most common reasons for a non-starting engine.

Importance of Regular Maintenance

Regular inspection and servicing based on these visual guides can extend the life of your machine. Routine checks for wear and tear, lubrication, and cleaning of components should be part of every maintenance schedule. Always refer to the diagram to ensure you’re addressing the right parts at the right time.

Understanding Tractor Components and Maintenance

Understanding the structure and functionality of tractor components is essential for ensuring its proper operation and longevity. Knowing how to identify and interpret the different parts, along with recognizing common issues, helps in maintaining optimal performance. This section will provide insights into the layout of critical elements, offer guidance on how to troubleshoot effectively, and give tips for performing regular maintenance.

How to Interpret the Tractor Component Layout

When tackling machinery maintenance, it’s crucial to have a clear view of the different parts and how they interconnect. A well-structured guide will provide a visual representation, labeling each key element. By understanding these illustrations, you can identify which part requires attention, making repairs more efficient. Focus on the major sections, like the engine, transmission, and hydraulic systems, as they play pivotal roles in the machine’s function.

Common Issues and Essential Repairs

Tractors often face a range of common problems, including engine failure, electrical issues, and mechanical breakdowns. By using a parts guide, it’s easier to pinpoint the faulty component. For example, if the machine fails to start, check the electrical system or fuel delivery system. Regular wear and tear in areas like the belts or brakes should also be addressed periodically. Understanding these components’ roles can help prevent costly repairs.

Routine Maintenance for Longevity

Proper upkeep is vital to keeping machinery in good working order. Follow a regular maintenance schedule to inspect critical components, such as the filters, belts, and fluid levels. Clean and lubricate moving parts to reduce friction and wear. Always refer to the schematic for specific details about each part to ensure you’re covering all necessary areas during your maintenance checks.