Maintaining and repairing agricultural machinery requires a clear understanding of its internal structure. A comprehensive guide to the various components is essential for anyone looking to troubleshoot, repair, or upgrade their equipment. Knowing the location and function of each part can make the maintenance process smoother and more efficient.

Accurate identification of individual components ensures that the right actions are taken during repairs. Proper knowledge also helps in ordering the correct replacement parts and understanding how each piece contributes to the overall function of the machine.

Understanding the intricacies of machinery allows operators to take proactive measures in preventing potential failures. With the right resources, users can confidently handle maintenance tasks and extend the lifespan of their equipment, ensuring optimal performance in all conditions.

Understanding Tractor Components

When working with heavy machinery, it is essential to comprehend how each part functions within the overall system. Understanding the various elements that make up the equipment helps in recognizing their roles in ensuring smooth operation. Knowledge of these components aids in effective troubleshooting, repair, and maintenance, providing users with the ability to extend the lifespan of their machinery.

Key Elements of a Tractor’s Structure

A tractor’s framework consists of numerous interconnected systems, each contributing to its overall performance. Key components such as the engine, transmission, hydraulics, and steering play crucial roles in how the machine operates. Each system must be well-maintained to prevent mechanical failure and ensure the tractor operates at full capacity.

Importance of Regular Maintenance

Routine checks of essential systems like the engine and hydraulic pumps are vital to ensure continuous functionality. By understanding the function of each part, operators can more effectively monitor the machine’s condition, identifying issues before they become major problems. Regular servicing also helps prevent costly repairs and downtime, allowing for more efficient work.

Knowing the function of every part means that you can take a more hands-on approach to keeping your equipment in top shape. Proper care, backed by detailed knowledge, leads to greater productivity and reliability over time.

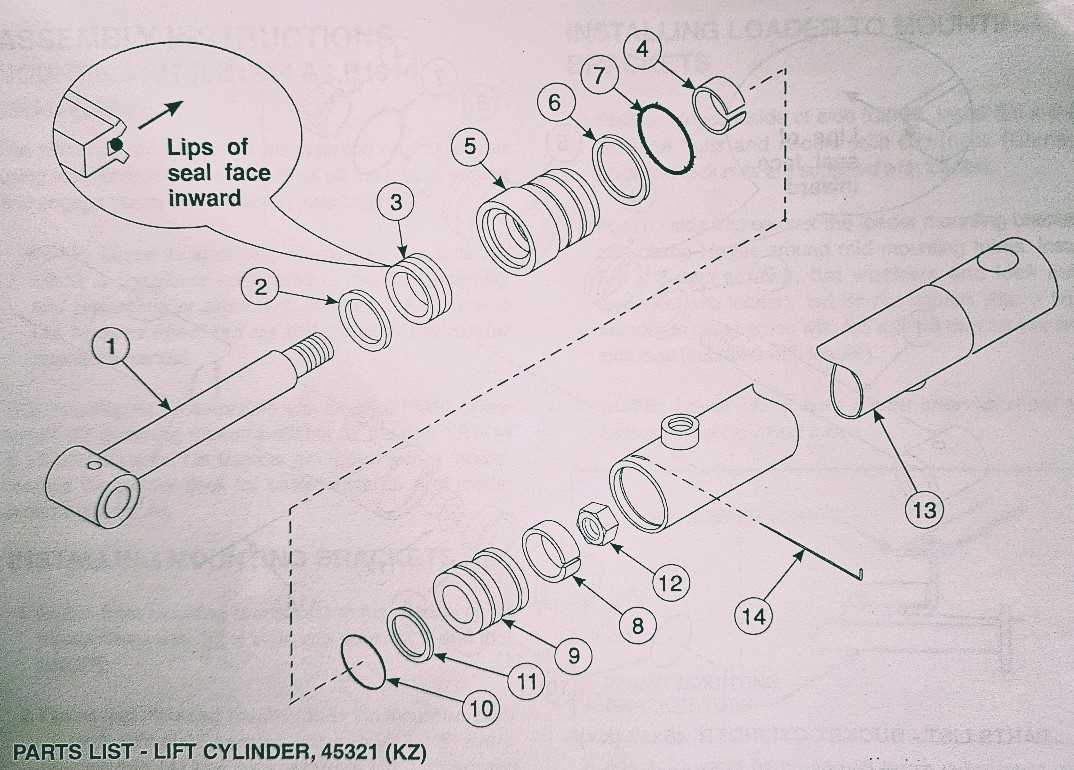

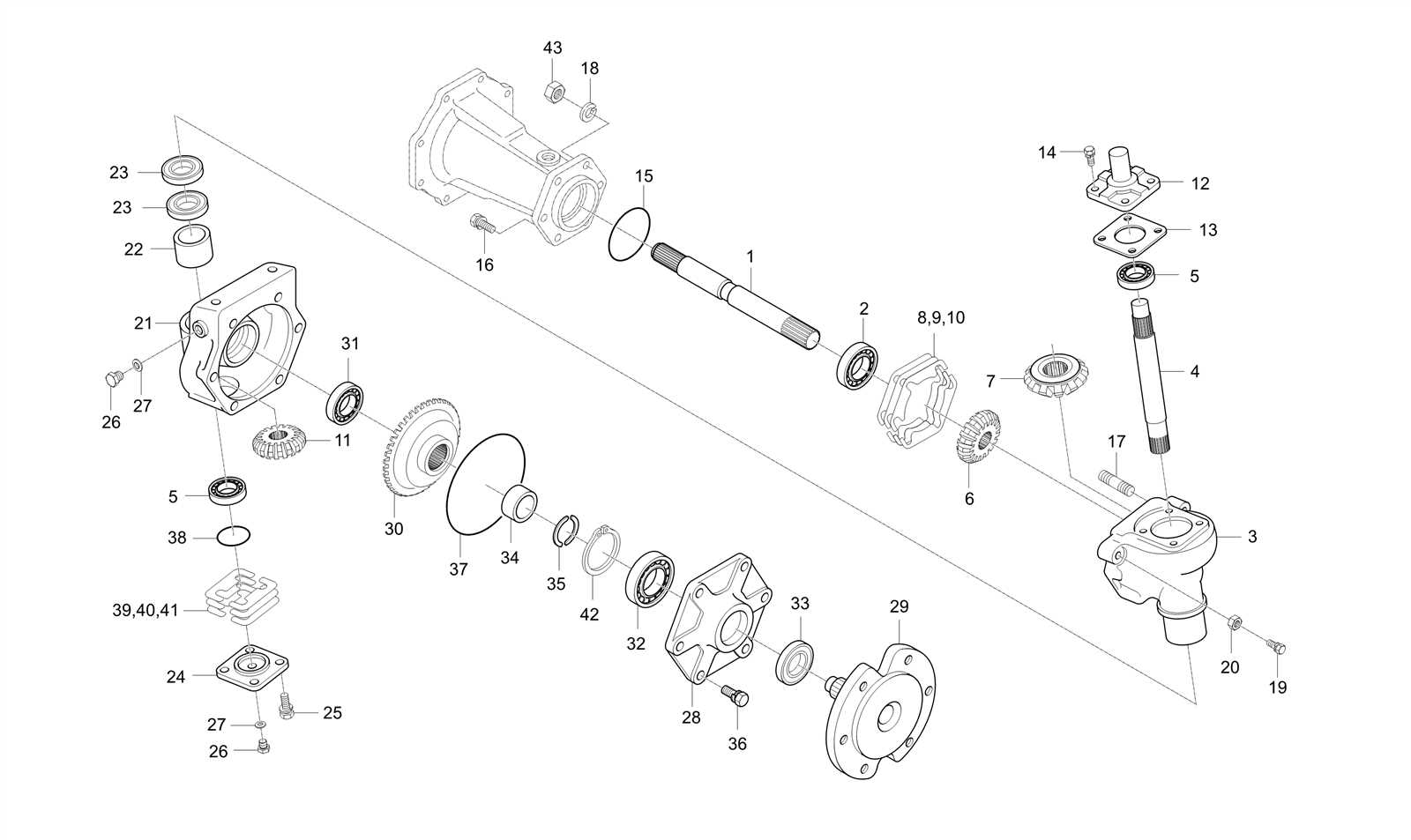

How to Read the Component Breakdown

Understanding how to interpret a visual representation of your machinery’s structure is essential for effective repairs and maintenance. A clear guide to identifying each element allows users to quickly locate and assess individual components, which is crucial when addressing mechanical issues. By learning to read these representations accurately, operators can streamline the troubleshooting process and avoid unnecessary disassembly.

Identifying Individual Parts

Each component in the schematic is typically labeled with a reference number or code, which corresponds to the specific part in the inventory. Paying attention to these identifiers helps you locate the correct replacement or accessory. Often, these illustrations are designed with clarity in mind, showing parts from various angles to provide a comprehensive understanding of their placement and function.

Interpreting System Relationships

In addition to identifying individual components, it is important to understand how they interact within the system. Parts are often grouped by their function or location within the machine. By recognizing these relationships, you can better understand the workflow of the entire system, ensuring that any repairs made will not disrupt the machine’s overall operation.

Essential Components for Tractor Maintenance

Maintaining a machine’s performance requires attention to its most critical systems. Regular servicing of key components ensures that the equipment runs smoothly and efficiently, preventing costly breakdowns and enhancing its longevity. Understanding which parts to focus on during maintenance can significantly improve operational reliability.

Engine and Transmission

The engine is the heart of any machine, and keeping it in top condition is paramount. Routine checks of oil levels, air filters, and belts are necessary for optimal function. Similarly, the transmission system must be regularly inspected to ensure that gears shift smoothly and the power is properly transmitted to the wheels. Proper lubrication and fluid changes are essential to prevent wear and tear on both systems.

Hydraulic System and Steering

Another critical system to monitor is the hydraulic mechanism, responsible for powering various attachments and functions. Regular checks of hydraulic fluid levels and seals can help avoid leaks and ensure smooth operation. Additionally, maintaining the steering system is crucial for safety and maneuverability. By keeping these systems in good working order, operators can improve the overall efficiency of their machine and avoid downtime during critical tasks.