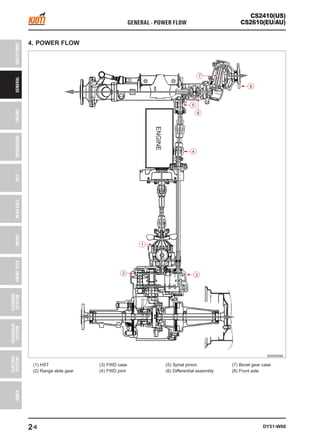

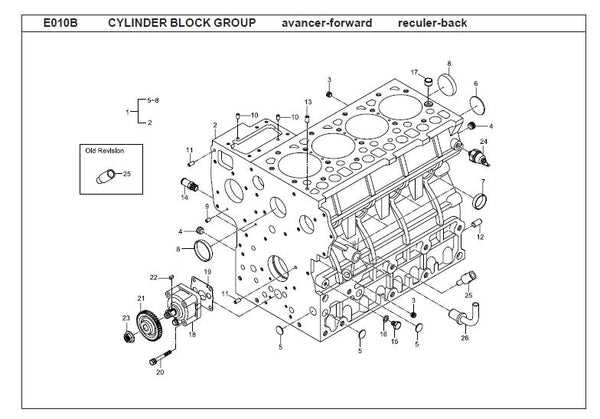

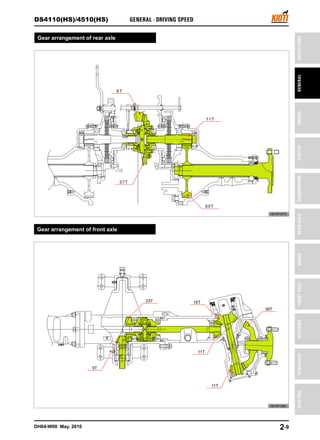

When it comes to maintaining complex equipment, having a clear visual representation of its internal components is essential. Such guides allow operators and technicians to identify and understand how each piece fits into the larger system, making repairs and replacements more efficient. Properly understanding these layouts can significantly reduce downtime and improve the overall longevity of your machinery.

Accurate identification of different elements within the equipment is key to diagnosing issues quickly. With a comprehensive guide, you can pinpoint which parts need attention, whether it’s for routine maintenance or addressing specific malfunctions. This approach ensures that repairs are done with precision, avoiding unnecessary replacements.

By familiarizing yourself with the structure and function of each component, you gain the knowledge needed to perform effective troubleshooting and maintenance tasks. This enhances both the performance and reliability of the equipment, contributing to its optimal operation over time.

Understanding Machinery Component Layouts for Repairs

Effective repair starts with knowing the internal structure of the equipment. A clear and detailed guide helps technicians and operators identify each element, understand its function, and recognize potential issues. This knowledge is crucial when performing repairs, as it ensures accurate and efficient work without the need for guesswork.

When approaching maintenance or repair tasks, it’s important to follow these key steps:

- Study the layout carefully: Thoroughly examine the visual representation to understand the placement and relationship between the various components.

- Identify specific parts: Use the guide to find the exact components that need attention, whether for replacement or maintenance.

- Understand the function: Knowing how each part works within the system allows you to make informed decisions during repairs and troubleshooting.

- Follow a systematic approach: Work step by step according to the guide to ensure all components are properly addressed and the equipment is restored to full functionality.

Having access to an accurate component map makes the repair process more predictable and less time-consuming. This not only reduces operational downtime but also prevents unnecessary damage to equipment. With proper use of the layout, even complex issues become more manageable.

How to Read Machinery Layouts Effectively

Understanding complex visual guides is crucial when working with machinery. These layouts provide a detailed view of the components, helping users identify parts and their functions within the system. Reading these guides effectively can greatly streamline troubleshooting and repair tasks by providing a clear map of where each part belongs and how they interact.

Start with the Overview

Before diving into the specifics, take a moment to study the overall view of the layout. This will give you a sense of the entire system’s organization and help you understand the placement of key components. Pay attention to the labels, as they will often provide valuable context for identifying each part.

Focus on Details and Relationships

Once you have an overview, zoom in on the individual components that are of interest. Focus on how these parts connect with one another and how they function together within the system. Identifying these relationships is essential for understanding the impact of each component and troubleshooting effectively.

By focusing on both the broad view and the finer details, you will be able to read and interpret machinery layouts with greater precision and confidence.

Common Machinery Components and Their Functions

Every machine consists of various elements that work together to ensure smooth operation. Understanding the role of each component is crucial for effective maintenance and repair. Some parts play vital roles in the overall functionality, while others may be more specialized but equally important in keeping the system running efficiently.

Here are some of the most common components found in many machines:

- Engine: The heart of any machine, responsible for powering the entire system. It converts fuel into mechanical energy, enabling all other components to function.

- Transmission: Transfers power from the engine to other parts, allowing the machine to move or perform specific tasks. It adjusts the speed and torque according to the needs of the operation.

- Hydraulic System: Utilizes fluid power to drive various functions, such as lifting or moving heavy loads. It is often used in systems requiring precise control and high force.

- Electrical System: Powers various controls, sensors, and other electronic components. It is crucial for starting the engine and ensuring smooth communication between different systems.

- Chassis: The frame that supports all other components, providing structural integrity and stability during operation.

Understanding the function of these elements will help you troubleshoot problems, maintain your machine effectively, and make the right decisions when it comes to repairs and replacements.