When working with complex machinery, having a clear understanding of each individual element is essential for both efficient operation and easy maintenance. Whether you are repairing a malfunction or upgrading your equipment, knowing how every component fits together can save both time and effort. By familiarizing yourself with the internal structure, you’ll be better prepared to troubleshoot issues and perform necessary replacements.

Maintenance and repairs are integral parts of owning any power tool, especially when frequent use takes a toll on various components. In such cases, referring to a detailed reference guide can help you identify and address problems with ease. This guide allows you to locate specific parts quickly, making it easier to replace worn-out pieces and ensure smooth functionality.

Additionally, having a clear view of the tool’s structure can improve your overall experience, whether you’re a seasoned professional or a DIY enthusiast. Understanding how each piece works together ensures that you can maximize the lifespan and efficiency of your equipment, ensuring you get the best performance for your needs.

Kobalt Table Saw Parts Overview

Understanding the key elements of your power tool is essential for efficient operation and maintenance. Each machine consists of multiple components that work together to ensure precision, stability, and safety. Knowing the function and location of these parts can simplify repair and replacement processes, leading to better performance and longevity of the tool.

Key Elements of the Tool

The core components that drive the functionality of your equipment include the motor, blade, and various adjustment mechanisms. These elements allow you to control speed, angle, and precision, which are crucial for achieving accurate results. Understanding how each part contributes to the overall operation ensures that you can troubleshoot any issues and make informed decisions about replacements.

Additional Features and Upgrades

In addition to the main functional components, there are several optional features and upgrades that can enhance your tool’s performance. Items such as safety mechanisms, dust collection systems, and specialized accessories allow for more precise work and a safer experience. Knowing which additional parts are compatible with your equipment can make a significant difference in its capabilities and the quality of your results.

How to Read a Kobalt Saw Diagram

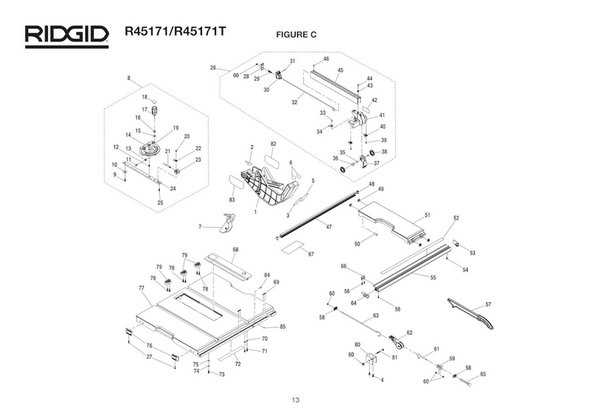

Understanding the layout and structure of your tool is crucial for effective repairs and maintenance. A visual guide can simplify the identification of each component, helping you pinpoint the exact piece that needs attention. By learning how to interpret these illustrations, you’ll be able to navigate your equipment’s internal workings with ease.

Identifying Key Components

Each guide typically breaks down the tool into its essential sections. The first step is to recognize the major elements such as the motor, drive system, and safety mechanisms. These parts are usually highlighted with clear labels, showing their placement and connections to one another. Being familiar with these key areas can help you quickly locate malfunctioning or worn-out parts.

Understanding Part Numbers and Labels

Once the components are identified, focus on the part numbers and descriptions. These numbers correspond to specific replacement items, allowing you to find the right pieces when purchasing or ordering replacements. Many diagrams also include detailed notes about the function of each part, helping you better understand how they interact within the entire system.

Common Kobalt Table Saw Part Replacements

Over time, regular use of power tools can lead to wear and tear on various components. Certain elements are more prone to damage and may need to be replaced to maintain optimal functionality. Identifying these components early on can save both time and money, ensuring that your tool continues to perform at its best.

One of the most commonly replaced items is the cutting blade. Blades naturally dull with use, affecting cutting performance. Additionally, the motor may eventually show signs of strain, requiring either repair or a full replacement. Other parts, such as the belts or switches, can also wear out and cause the tool to malfunction, making it important to keep an eye on these elements.

Regularly inspecting your equipment and understanding which parts are most likely to need replacement will help keep it running smoothly and prevent unexpected downtime.