Maintaining a small engine requires a clear understanding of its internal mechanisms and individual components. For anyone looking to troubleshoot or enhance performance, it is essential to identify key parts and understand their roles within the system. Proper maintenance not only extends the life of the engine but also ensures optimal functionality over time.

Accurate identification of each element is crucial when diagnosing issues or performing repairs. With a visual reference, recognizing where each component fits into the bigger picture becomes simpler and more efficient. A thorough breakdown of the engine’s layout aids in pinpointing potential problems quickly and ensures that each part functions in harmony.

In this guide, we will explore how to approach engine maintenance, offering valuable insights into the layout and functionality of critical components. Whether you are a seasoned mechanic or a novice enthusiast, this information will equip you with the tools needed for a deeper understanding of engine systems.

Understanding Engine Components

Engines consist of a variety of crucial elements that work together to ensure smooth operation. Each component plays a specific role, from generating power to regulating airflow and fuel delivery. Understanding how these parts interact is key to diagnosing issues and performing effective repairs or maintenance.

The primary components of an engine include the ignition system, fuel system, cooling system, and exhaust. Each part is designed to contribute to the overall function, whether it’s ensuring combustion efficiency, preventing overheating, or facilitating the expulsion of exhaust gases. A well-maintained engine relies on the proper performance of these individual components, and any malfunction can lead to reduced efficiency or failure.

By familiarizing yourself with the various parts and their functions, it becomes easier to identify problems, perform regular checks, and replace damaged elements. This knowledge is invaluable for anyone seeking to maintain or repair their engine over time, as it allows for quicker troubleshooting and more informed decisions when dealing with specific issues.

How to Read an Engine Component Breakdown

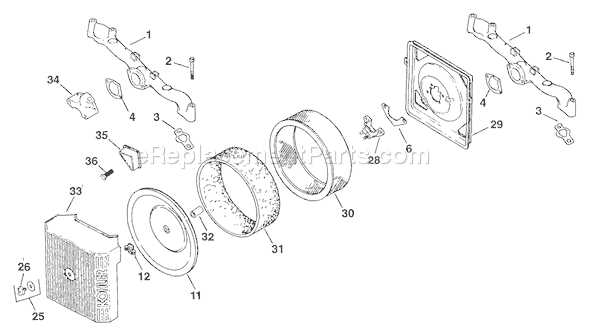

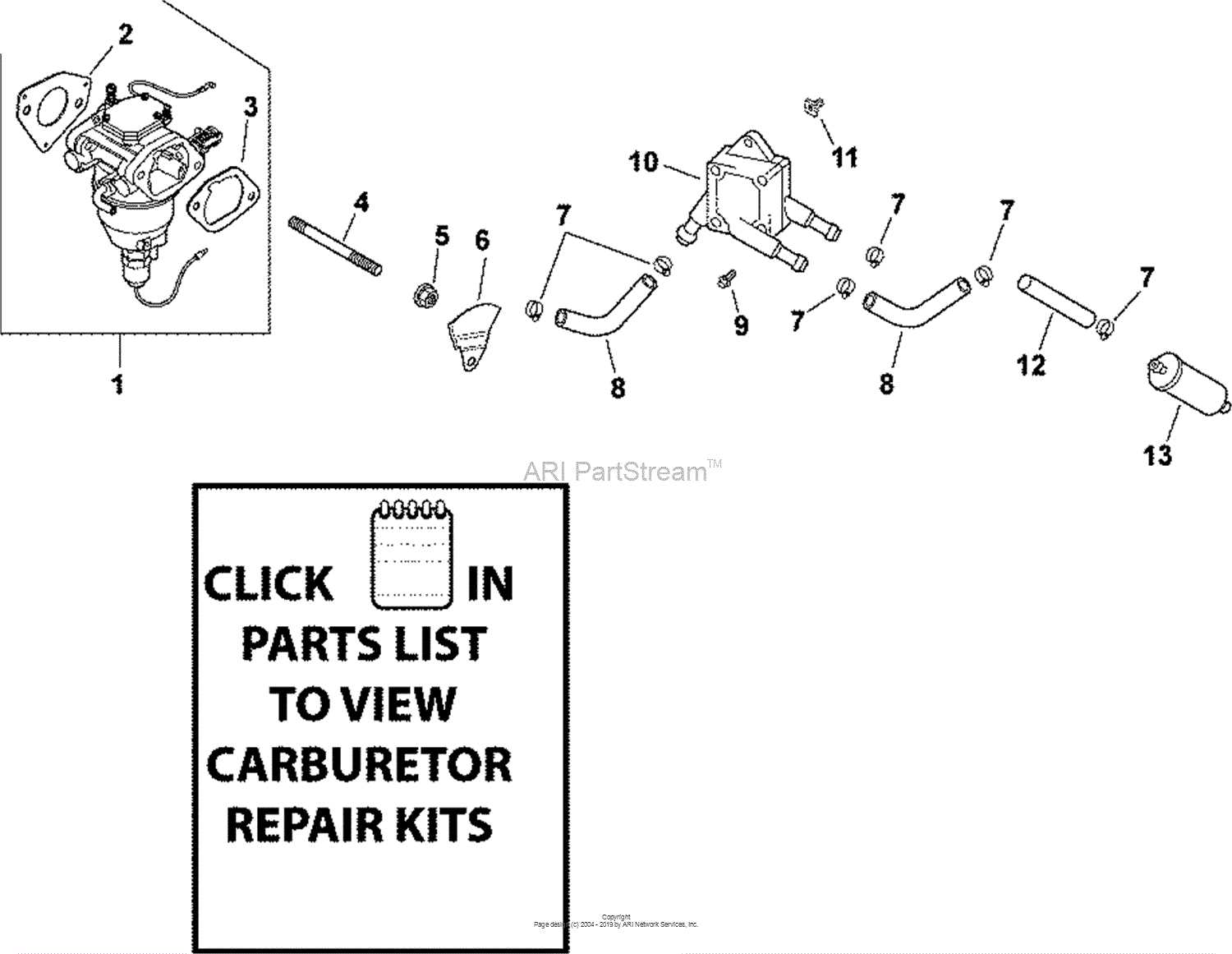

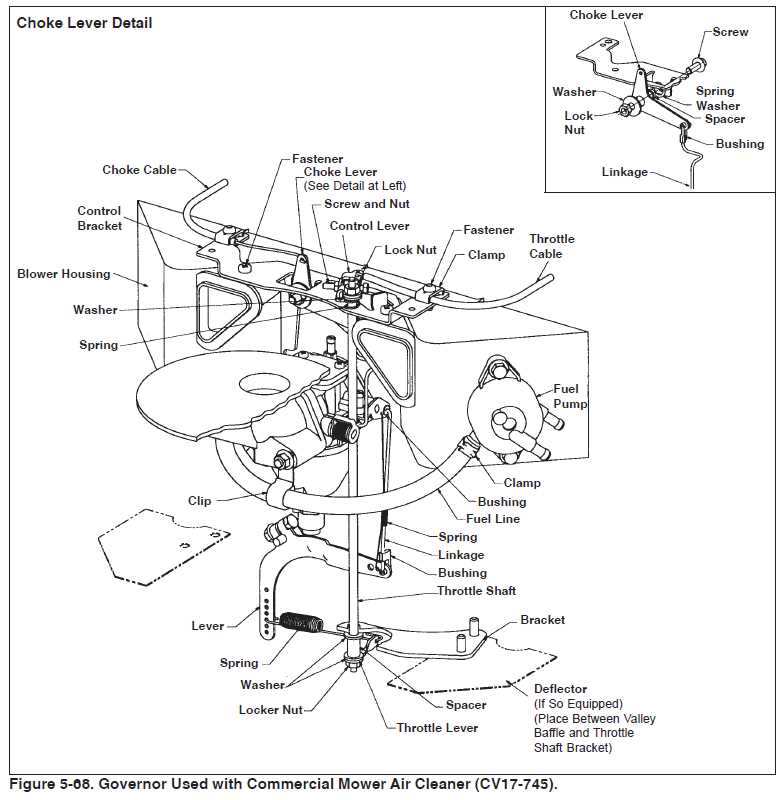

Understanding an engine’s component layout is essential for effective repairs and maintenance. A breakdown illustration serves as a detailed map, showing the exact placement and connection of each element within the system. Reading and interpreting these visuals correctly allows for more accurate identification of parts, ensuring that you can address issues with precision.

These breakdowns typically feature clear labels and numbers corresponding to specific parts. Each part is usually shown in a logical arrangement, helping you trace how components interact with each other. It is important to familiarize yourself with the layout, as this enables you to easily locate parts and understand their role in the engine’s overall performance.

When using these visuals for troubleshooting or repairs, be sure to cross-reference the numbers with an accompanying list or manual. This process will guide you through the identification of the correct part, making replacements or repairs simpler and more efficient. Knowing how to interpret these diagrams is a vital skill for anyone working with small engines.

Common Issues and Solutions for Engine Components

Like any mechanical system, engines often face common problems that can affect their performance. These issues are typically related to the wear and tear of individual elements or improper maintenance. Identifying these issues early on can prevent further damage and ensure smooth operation over time.

One frequent problem is inadequate fuel delivery, which can be caused by a clogged fuel filter or faulty fuel pump. This issue leads to engine misfires or stalling. Regular inspection and replacement of these components can resolve such issues and restore normal function. Another common concern is overheating, often resulting from a malfunctioning cooling system, such as a broken fan or a clogged radiator. Ensuring these parts are in good condition is essential to prevent overheating and subsequent engine damage.

Additionally, worn-out ignition components, such as spark plugs or ignition coils, can lead to starting issues or poor engine performance. Replacing these parts at regular intervals can improve starting reliability and overall efficiency. By understanding these typical problems and their solutions, you can maintain the engine’s health and avoid costly repairs.