When it comes to maintaining or repairing small engines, a clear visual guide to their components is invaluable. This guide helps users quickly identify individual parts, ensuring accurate repairs and replacements. Whether you’re a professional mechanic or a DIY enthusiast, having a detailed layout can save time and reduce mistakes.

By exploring how different parts interact with each other, you can gain a deeper understanding of the engine’s overall functionality. This knowledge not only improves repair efficiency but also enhances your ability to troubleshoot problems. Recognizing key elements within the layout ensures you know exactly where to focus your attention during the maintenance process.

In this guide, we will walk through the essential components that make up the engine system. Understanding each section will equip you with the necessary tools for successful repairs, ultimately extending the life of the equipment. Let’s dive into the details of the layout and break down what makes each part unique.

Understanding the Engine Components

To maintain or repair any engine effectively, it’s crucial to first familiarize yourself with its individual components. Each piece plays a vital role in ensuring smooth operation, and understanding their function helps in identifying issues more accurately. Knowing the location and role of every element enables better decision-making when it comes to troubleshooting or replacement tasks.

Main Elements of the Engine

The core sections of the engine include the power generation system, the fuel delivery mechanism, and the exhaust setup. These major components work in harmony to power the machine and ensure it runs efficiently. Identifying each part’s purpose will guide you through both regular maintenance and more complex repairs.

Interconnection of Engine Sections

Understanding how the different sections interact is just as important as recognizing their individual roles. The fuel system must communicate seamlessly with the ignition system, while the exhaust system helps control emissions. This connection ensures that the engine operates at peak performance, and diagnosing any malfunction in one section often leads to identifying issues in others.

Key Components in the Engine Layout

Understanding the primary elements of an engine layout is essential for proper maintenance and troubleshooting. These key components are responsible for various functions such as power generation, fuel management, and exhaust control. Each piece has its unique role in ensuring optimal performance, and knowing them helps in pinpointing any issues more effectively.

Essential Elements

Below are the fundamental components that contribute to the engine’s operation:

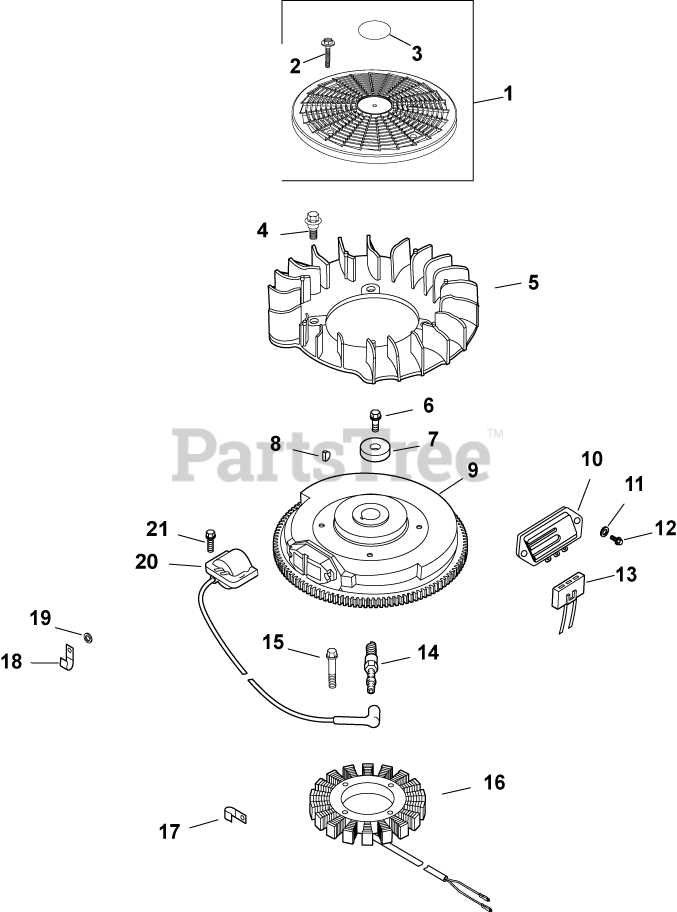

- Ignition System – Responsible for sparking the combustion process.

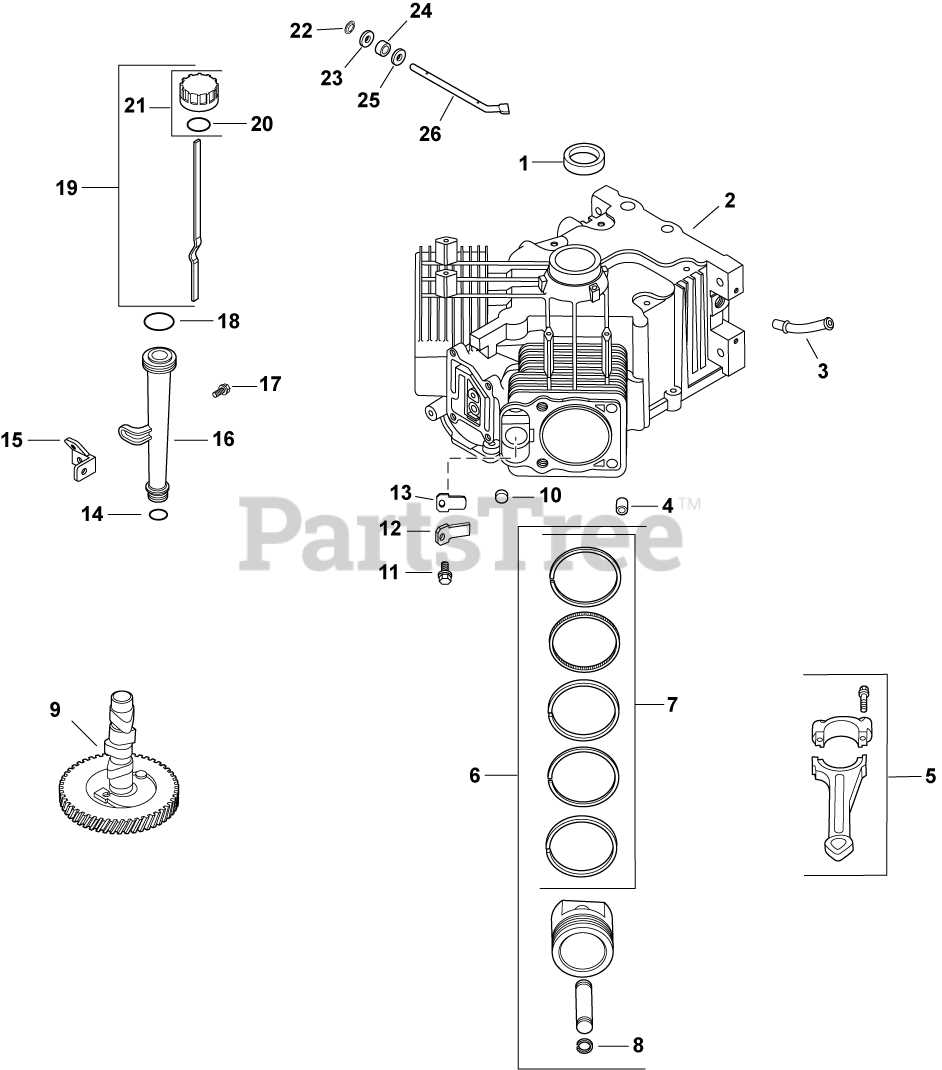

- Fuel System – Delivers the necessary fuel for engine operation.

- Cooling System – Prevents overheating by maintaining optimal temperature levels.

- Lubrication System – Reduces friction and prevents wear between moving parts.

- Exhaust System – Directs harmful gases away from the engine and out of the machine.

Understanding the Functionality

Each of these components works in tandem with others to ensure the engine operates smoothly. For example, the ignition system must work with the fuel system for proper combustion, while the cooling system must manage the heat produced during operation. Familiarity with these elements and their interactions makes it easier to maintain, repair, and optimize engine performance.

How to Use the Layout Effectively

To maximize the utility of an engine layout, it’s important to know how to read and interpret the various sections and components shown. A clear visual guide can help you quickly locate parts and understand how they fit into the overall system. By using this guide strategically, you can streamline your repair or maintenance process.

Start by familiarizing yourself with the key sections of the layout. Focus on identifying critical components such as the ignition system, fuel delivery system, and cooling mechanisms. Once you know where these elements are, you’ll be able to quickly assess their condition and identify potential problems.

Additionally, when replacing or repairing specific sections, refer to the layout to ensure that you select the correct part and install it in the right location. Consulting the layout regularly during repairs helps prevent mistakes and ensures all components are reassembled properly for optimal engine performance.