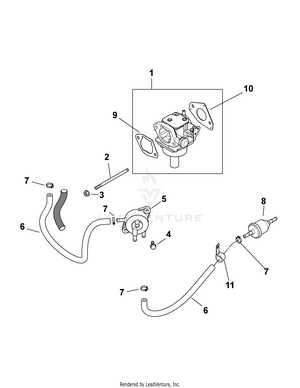

When maintaining or repairing small engines, understanding the layout and structure of key components is essential. Having a clear visual representation helps in identifying parts and knowing how they fit together. This knowledge is crucial for both troubleshooting issues and performing regular maintenance tasks.

By studying the engine’s components, users can gain insights into how each part functions and its role within the system. With the right approach, diagnosing problems becomes more straightforward, ensuring that repairs are efficient and effective.

In this guide, we will explore how to interpret these illustrations, making it easier to carry out tasks like replacing worn-out elements or adjusting settings. Whether you’re a seasoned mechanic or a novice, this information is valuable for ensuring the longevity and performance of your engine.

Understanding the Engine Layout

When dealing with engine maintenance or repairs, a solid understanding of its layout is crucial. Each engine is composed of numerous interconnected components that work together to ensure proper functioning. Recognizing these parts and their roles within the system allows for better problem-solving and more efficient repairs.

Engine Configuration and Core Components

The layout consists of several key areas, such as the power generation unit, cooling system, and fuel intake system. By understanding how these parts are arranged and how they interact, mechanics can more easily identify potential issues and perform maintenance tasks. For example, the ignition system’s position can significantly influence its ease of access during repairs.

Importance of Properly Interpreting the Layout

Proper interpretation of the engine layout not only aids in repairs but also plays a role in optimizing engine performance. Identifying each component’s location can prevent unnecessary disassembly, saving both time and effort. This understanding also helps with regular maintenance, ensuring that every part operates at peak efficiency throughout its lifespan.

Key Components of the Engine

Understanding the main components of an engine is essential for effective maintenance and troubleshooting. Each part plays a specific role in the engine’s operation, and knowing their functions helps in identifying potential issues. Key elements of the system are carefully designed to work in harmony, contributing to the overall performance and longevity of the engine.

Ignition and Fuel Systems

The ignition system is responsible for starting the engine by creating a spark to ignite the fuel-air mixture. This system includes the spark plug, ignition coil, and flywheel. The fuel system, on the other hand, manages the delivery of fuel to the engine. It includes components like the carburetor or fuel injectors, which regulate the amount of fuel mixed with air for combustion.

Cooling and Lubrication Systems

Engines generate heat during operation, and the cooling system helps to dissipate this heat to prevent damage. The cooling system consists of components such as the radiator, thermostat, and coolant passages. The lubrication system, including the oil pump and filters, ensures that all moving parts are properly lubricated, reducing friction and wear while maintaining smooth operation.

How to Use the Engine Component Layout

Utilizing a visual layout of an engine can significantly simplify maintenance and repair tasks. These illustrations provide a clear view of how various components are organized, helping users to identify, remove, or replace parts efficiently. Understanding how to read and interpret these layouts is essential for performing accurate repairs and ensuring the engine runs smoothly.

Identifying Key Components

The first step in using an engine layout is to familiarize yourself with the different components shown. Focus on the labels and symbols that correspond to various parts, such as the ignition system, fuel intake, and cooling mechanisms. By cross-referencing these elements with the engine’s actual configuration, you can pinpoint the exact location of each part for easier troubleshooting.

Following Step-by-Step Instructions

Many layouts include step-by-step guides that offer instructions on how to disassemble or reassemble the engine. These visual guides are invaluable for ensuring that no part is missed or improperly handled during repairs. Following these instructions closely helps maintain the engine’s integrity and ensures a smoother process when replacing or adjusting parts.