When it comes to maintaining and repairing small engines, understanding the individual components is essential for smooth operation. This guide focuses on providing an in-depth look at the various parts that make up a typical engine system. By familiarizing yourself with how each piece functions and how they connect, you’ll gain a better understanding of the engine’s performance and troubleshooting processes.

Having a clear visual reference of the internal workings is crucial. It helps in identifying specific components, their placement, and the way they interact with each other. Whether you’re a seasoned mechanic or a DIY enthusiast, this resource offers valuable insights to assist in repairs, upgrades, or general maintenance.

Effective maintenance relies on knowing which parts need attention and how to approach repairs or replacements. A well-organized view of the engine’s structure allows you to efficiently diagnose issues and ensure the proper functioning of each part. Armed with this knowledge, you can perform tasks more confidently and extend the life of your machinery.

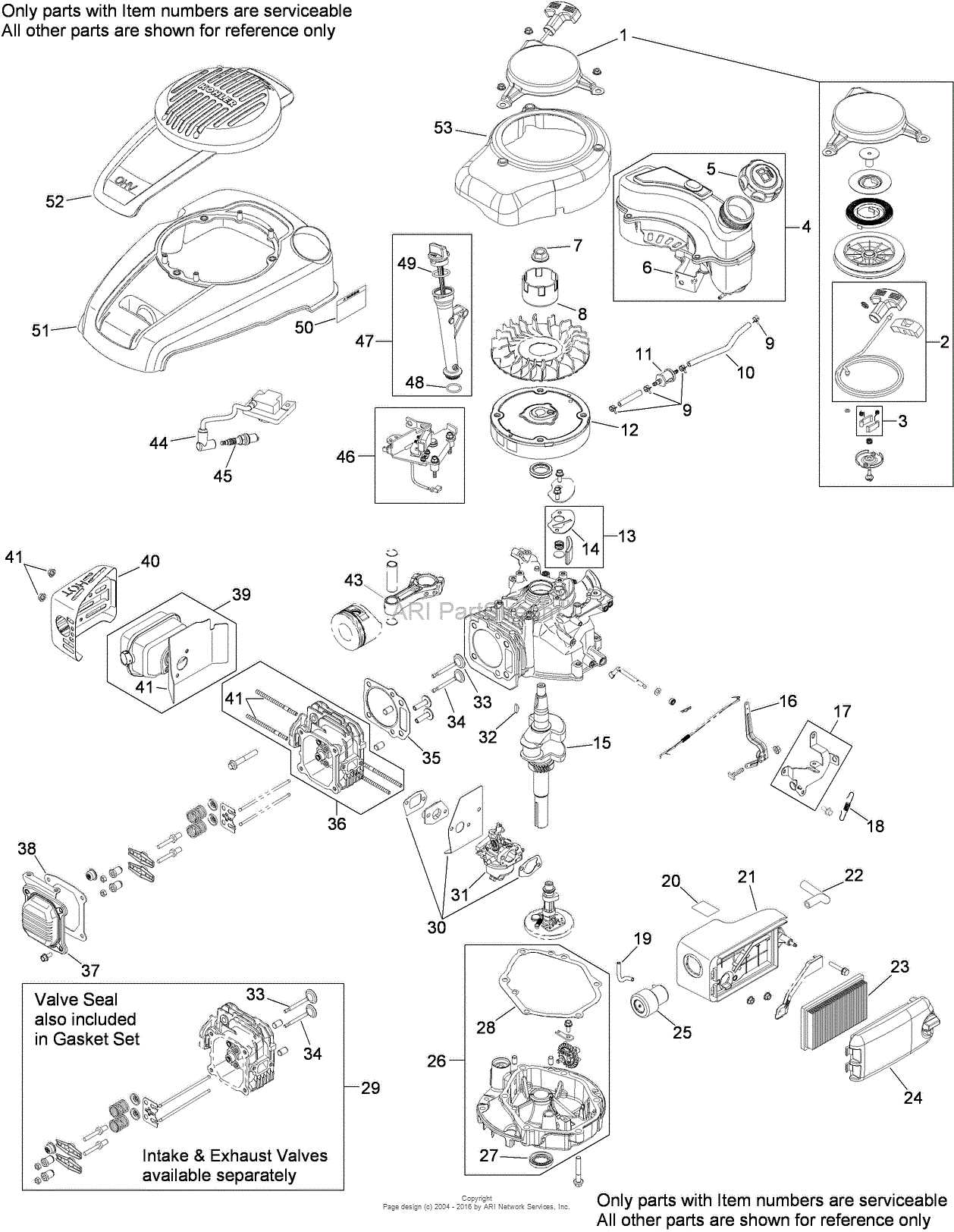

Engine Components Breakdown

Understanding the key elements of an engine is crucial for effective maintenance and repair. Each part plays a specific role in ensuring the engine runs smoothly and efficiently. By examining these components closely, you can identify potential issues and address them before they cause significant damage. The breakdown of these components allows for a more thorough approach to troubleshooting and enhances the overall lifespan of the engine.

Essential Engine Elements

Every engine consists of several critical pieces, including the fuel system, ignition components, and air intake system. The fuel system is responsible for supplying the necessary fuel to the engine, while the ignition system ensures the proper timing for combustion. The air intake system allows the engine to draw in air, which is crucial for the combustion process. Each of these components needs to work harmoniously to achieve optimal performance.

Mechanical and Moving Parts

In addition to the core systems, mechanical components such as the crankshaft, valves, and pistons are essential for converting energy into motion. These moving parts endure high levels of stress and wear over time, requiring regular inspection and maintenance. The crankshaft transfers power from the combustion process to the engine’s output, while the pistons and valves regulate air and fuel flow, ensuring efficient combustion.

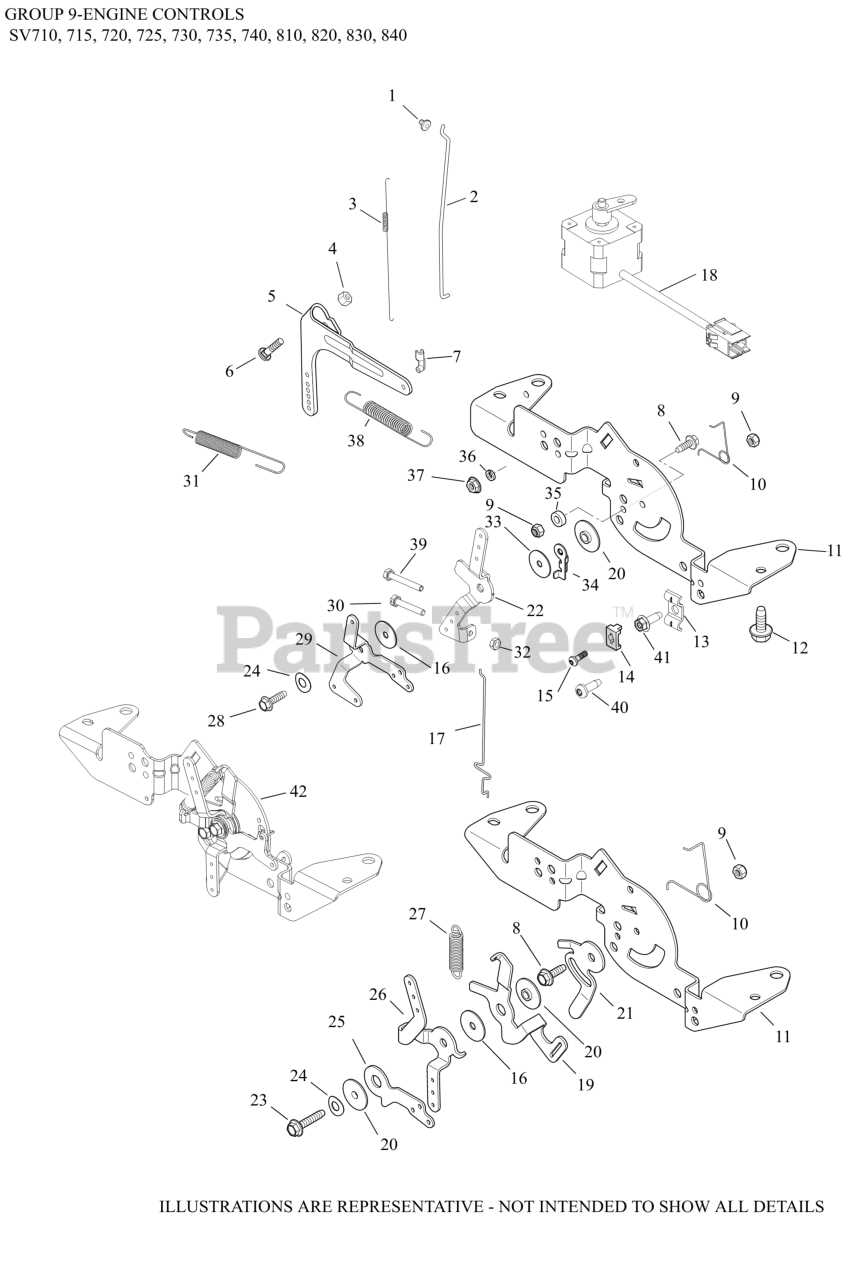

Understanding Key Parts and Functions

To fully comprehend how an engine operates, it’s essential to understand the role of its key components. Each element, from fuel delivery to exhaust management, plays a vital role in ensuring the system functions efficiently. By identifying these parts and their respective functions, you gain a clearer perspective on how the engine works and how each part interacts to maintain optimal performance.

Fuel and Ignition Systems

The fuel system delivers the necessary fuel to the engine, while the ignition system ensures the right spark is generated at the correct time for combustion. Together, these systems ensure that the engine starts and operates smoothly, providing power to the machinery. A malfunction in either system can lead to poor engine performance or failure, making their upkeep crucial for reliable operation.

Airflow and Exhaust Management

The intake system brings in fresh air, which is necessary for combustion, while the exhaust system expels the gases created during this process. Proper airflow is critical for efficient operation, as it directly impacts fuel consumption and engine power. Maintaining these systems ensures that the engine runs at peak performance and minimizes harmful emissions.

How to Read the Assembly Guide

Interpreting an assembly chart is essential for identifying the location and function of each component within a machine. These visual representations allow you to understand how the different elements fit together, making it easier to identify issues, replace parts, or perform maintenance. A clear guide can simplify complex repairs, ensuring you have the correct components and understanding before starting the task.

Locating Components

Each component is typically labeled with a reference number or name. These identifiers are usually linked to a list or manual, which provides further details about each part’s specifications and functions. By referencing the guide, you can quickly identify the necessary parts, making the process of repairs or replacements much more efficient.

Understanding Connections and Placement

The assembly chart will often show how the different parts interact with one another. Pay attention to the placement and orientation of each component, as this will help you assemble or disassemble the system properly. Knowing how the components connect ensures that each piece works harmoniously with the others, preventing any assembly errors that could lead to malfunction or damage.