Understanding the structure and functionality of farming machinery is essential for proper maintenance and repair. With a clear illustration of each component, users can identify critical parts and gain insight into their specific roles in the system. This knowledge helps enhance operational efficiency and extends the lifespan of the equipment.

Detailed visual representations serve as a vital tool for anyone involved in maintaining or fixing agricultural tools. By breaking down complex machinery into understandable sections, these guides simplify the troubleshooting and repair process, ensuring that users can address issues swiftly and accurately.

Learning how to interpret these component layouts provides a significant advantage in performing routine checks or more advanced repairs. Whether you’re a seasoned technician or a farmer looking to handle basic repairs independently, mastering the breakdown of each unit will prove invaluable in preventing downtime and optimizing performance.

Understanding Kuhn GF 5202 THA Components

When working with agricultural machinery, it is crucial to understand how each element functions within the system. Each component plays a specific role in ensuring smooth operation, and recognizing these parts can significantly improve troubleshooting and maintenance efforts. A clear understanding of these individual elements can help prevent costly repairs and improve the overall performance of the equipment.

Key Components and Their Functions

Each machine is made up of various parts that work together to achieve a specific goal. For example, drive systems, hydraulics, and control units each have their dedicated purpose. Familiarity with these components allows users to quickly identify which section requires attention, reducing downtime during operation.

How to Identify and Manage Components

Knowing the different parts also means knowing how to manage them effectively. Regular inspections, lubrication, and part replacements are essential to keeping the machine in optimal working condition. By having an in-depth understanding of these elements, you can also predict potential issues before they arise, enhancing the longevity of the equipment.

Visualizing the Parts Breakdown for Maintenance

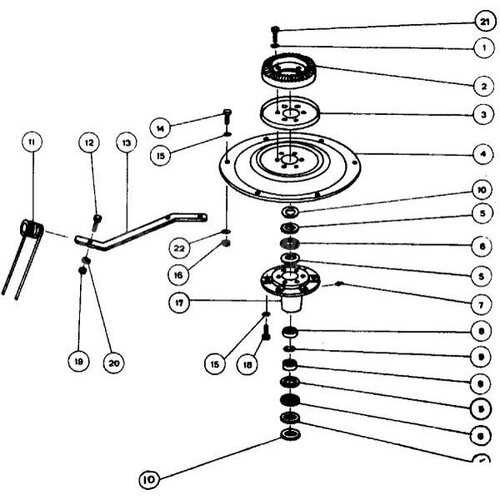

Effective maintenance begins with a clear understanding of the machine’s components. By visualizing how each part fits into the whole system, users can efficiently identify and address potential issues. This approach not only saves time but also prevents unnecessary wear and tear on the equipment.

Breaking down the equipment into smaller sections allows for a more focused inspection. Here’s how visualizing the structure can aid in the maintenance process:

- Focused Inspections: By understanding the layout of each section, maintenance can be performed more systematically, preventing missed components.

- Predictive Maintenance: Visualizing the parts helps to foresee which areas are most likely to wear out or need attention.

- Faster Repairs: A clear overview allows technicians to locate faulty parts quickly, minimizing downtime.

With the breakdown clearly mapped out, maintenance tasks such as lubrication, tightening, and replacing worn components can be carried out with precision and ease. A well-visualized system also ensures that users don’t overlook critical elements during routine checks.

How to Use the Kuhn Parts Diagram Effectively

To maximize the efficiency of any maintenance task, understanding how to use visual references of equipment components is crucial. These illustrations provide an organized way to identify individual parts and their connections, making it easier to follow repair procedures and perform accurate inspections. Proper use of these guides ensures that you can pinpoint issues with precision and avoid costly mistakes.

To use these visual guides effectively, start by familiarizing yourself with the layout of each section. Recognize key components and understand how they interact within the system. This awareness allows you to navigate the guide quickly and efficiently when performing diagnostics or repairs.

Additionally, always refer to the diagram during routine maintenance checks. It serves as a quick reference to verify if all parts are intact and functioning as they should. Keeping this guide nearby during repairs helps reduce errors and ensures that each task is completed properly.