When it comes to farming machinery, ensuring proper functioning is crucial for optimal performance. Understanding the individual components and how they work together is key to keeping your equipment in top shape. This guide aims to simplify the process of identifying and maintaining vital machine elements, allowing for smoother operations and reduced downtime.

Proper upkeep of these machines involves not only knowing their key parts but also learning how to recognize signs of wear and tear. With clear illustrations and thorough explanations, this resource will help you locate and manage the essential sections of your machinery for easy repairs and replacements. By staying proactive, you can avoid costly breakdowns and enhance the longevity of your equipment.

Understanding Key Components of Agricultural Machinery

For effective operation, every piece of farming equipment consists of multiple interconnected elements, each playing a vital role in its overall function. Whether it is for cutting, collecting, or performing other tasks, understanding the layout and roles of these components ensures that you can troubleshoot, maintain, and replace parts efficiently. This knowledge helps in reducing operational risks and improving the machine’s performance over time.

Identifying Essential Mechanisms

The primary mechanisms in any agricultural tool are typically designed to withstand the demanding conditions of farm work. These crucial systems often include drive shafts, blades, and other moving parts that ensure proper cutting or handling of crops. Each mechanism has its own specifications and requires routine checks to maintain efficiency and avoid breakdowns.

Common Wear and Tear Indicators

While each part serves a distinct purpose, they also experience wear and tear from constant use. Common indicators of wear include increased vibrations, inefficient cutting, or unusual noises from the machine. Recognizing these early signs allows for timely maintenance or replacement, preventing more serious damage and extending the life of the equipment.

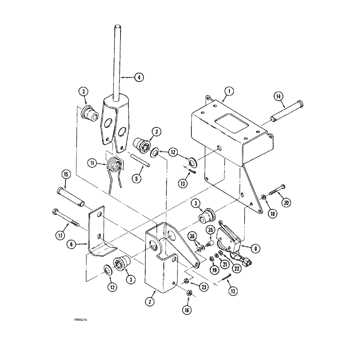

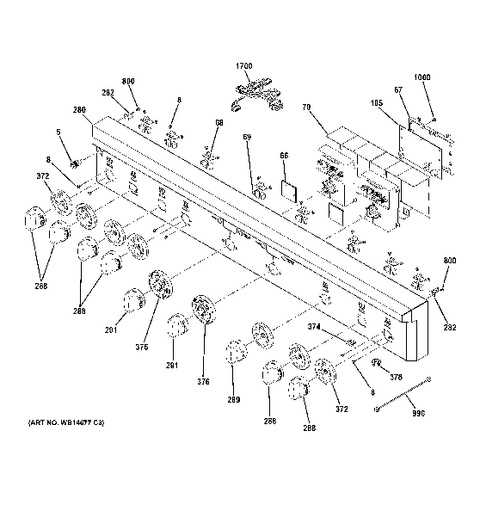

Identifying Key Parts in the Diagram

Understanding the structure of any agricultural machinery is essential for effective maintenance and repair. By familiarizing yourself with the layout and labeling of each component, you can easily locate the required parts and ensure that everything functions as intended. The diagrams serve as a helpful tool for visualizing these critical sections, making it easier to identify and manage specific elements when needed.

Locating Core Functional Elements

The core components of a machine, such as the cutting system, drive mechanisms, and adjustment controls, are typically marked with clear identifiers in the diagram. Recognizing these elements helps operators to quickly pinpoint the areas that require attention, whether for repairs or regular upkeep. Each labeled part is integral to the overall performance, so understanding their placement is key to effective machine operation.

Understanding Connections and Flow

Many machines rely on the precise interaction between different components to work efficiently. Diagrams highlight these connections, showing how each part is linked to others, such as the relationship between power sources, transmission systems, and working tools. Knowing how these elements interconnect will help you troubleshoot issues related to performance or malfunction.

How to Maintain Agricultural Equipment Components

Regular maintenance of machinery is crucial for ensuring long-term performance and avoiding unexpected failures. By adhering to proper maintenance practices, operators can extend the lifespan of essential systems and prevent costly repairs. Understanding how to care for the various elements of your machine will allow you to keep it running smoothly and minimize downtime during the busiest seasons.

Routine Inspection and Lubrication

One of the most important tasks in maintaining machinery is conducting routine inspections. Checking for any signs of wear, loose bolts, or misalignment helps identify potential problems early. Additionally, lubrication of moving parts, such as the transmission and cutting systems, is essential to ensure smooth operation and reduce friction, which can lead to premature wear.

Cleaning and Adjustments

Cleaning the machinery regularly prevents the buildup of dirt and debris, which can negatively impact the performance of the working components. Pay special attention to areas that come into direct contact with soil or crops, as these can accumulate material that affects functionality. Additionally, periodic adjustments to settings like tension or blade alignment are necessary to maintain optimal efficiency and achieve the best results during operation.