Understanding the key components of mowing machinery is crucial for maintaining optimal performance and ensuring longevity. Knowing how each part functions and fits together will help users effectively troubleshoot, replace, and maintain their equipment.

In this guide, we will explore the essential elements of your mower, offering a detailed view of its construction and providing helpful insights on how to manage repairs and replacements. Whether you’re dealing with worn-out components or simply performing routine upkeep, a solid grasp of the assembly will make the process easier.

By examining the system layout and understanding the role of each individual component, you’ll be empowered to perform maintenance tasks with confidence. Proper care and attention to each part will improve efficiency, prevent unexpected failures, and extend the life of your machinery.

Kuhn GMD 600 Key Components Explained

Each piece of mowing equipment is built with specific elements that contribute to its efficiency and functionality. Understanding how these components interact within the system helps ensure smooth operation and simplifies troubleshooting. In this section, we will break down the main parts that make up the machinery, highlighting their functions and how they work together.

The frame serves as the backbone of the unit, providing structural integrity and support for all other elements. Attached to the frame are various mechanical components that enable movement, control, and adjustment. These parts include the cutting mechanism, which is responsible for achieving a clean, even cut, and the drive system, which powers the entire operation.

Other essential components, such as the safety mechanisms and adjustment features, ensure safe and accurate operation. Understanding how each part contributes to the overall performance of the machine can make a significant difference in both its maintenance and day-to-day usage.

Understanding the GMD 600 Parts Layout

Familiarizing yourself with the layout of the various components within your mowing system is essential for efficient operation and easy maintenance. By examining the arrangement of these key elements, you can better understand how each part contributes to the overall functionality of the machine. This knowledge will help you identify potential issues early and manage repairs or replacements with confidence.

Component Arrangement and Interaction

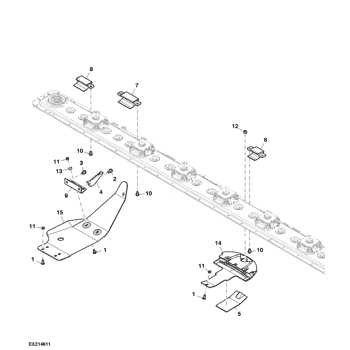

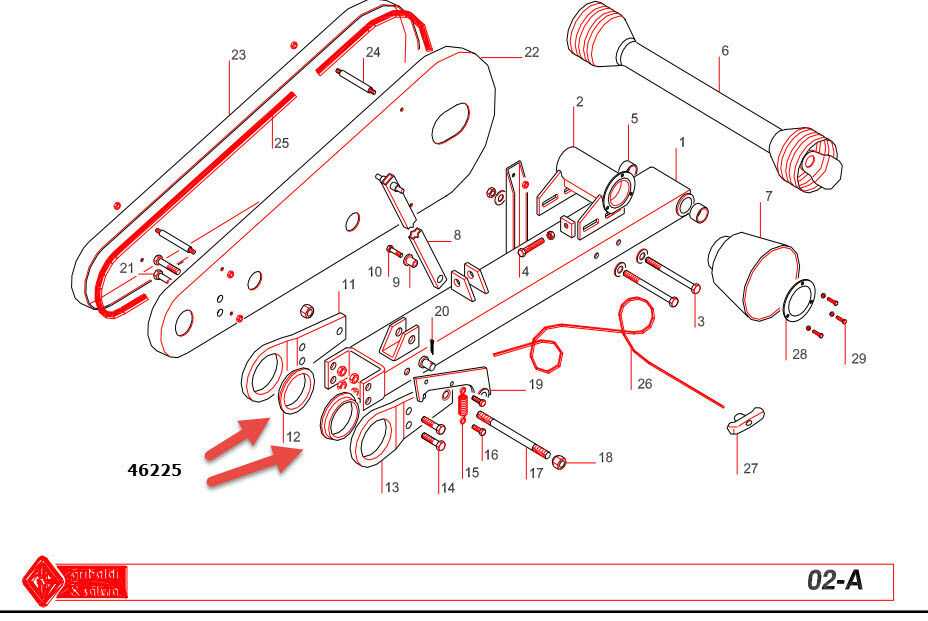

The layout of the machine is designed to ensure smooth interaction between the different systems. From the power source to the cutting mechanism, each part is strategically placed to maximize performance and minimize wear. The placement of moving parts, such as the drive shaft and blade assemblies, plays a critical role in preventing damage and ensuring reliability during use.

Layout for Efficient Maintenance

Understanding how the system is structured makes it easier to perform routine inspections and maintenance tasks. By knowing where each part is located and how it functions, you can quickly assess the condition of critical elements and replace or adjust them as needed. This proactive approach helps prevent unexpected breakdowns and reduces downtime.

How to Replace Kuhn GMD 600 Parts

Replacing worn-out or damaged components is essential for maintaining the performance and longevity of your machinery. Understanding the correct procedure for part replacement ensures that the machine continues to operate smoothly. This section will guide you through the necessary steps to replace critical elements effectively, allowing for proper installation and minimizing the risk of further issues.

Preparation for Replacement

Before starting any replacement, it is crucial to ensure that the machine is powered off and all safety protocols are followed. Gather the necessary tools and replacement components. Ensure compatibility by checking the specifications of each part to be replaced. Proper preparation can save time and avoid mistakes during the replacement process.

Step-by-Step Replacement Process

Begin by carefully removing the damaged part. Use the appropriate tools to avoid damaging surrounding components. Once the old part is removed, compare it with the new one to ensure a proper fit. Install the new part securely following the manufacturer’s instructions. After installation, check all connections and perform a test to verify functionality. Regularly inspect the replaced components to ensure they are functioning as intended.