Effective operation and maintenance of agricultural machinery require a clear understanding of its key components. Properly identifying and maintaining each element ensures efficiency and durability. In this section, we will explore the structure of a popular farming tool, focusing on its individual elements and their functions.

Identifying the key components is crucial for anyone involved in machinery upkeep. By understanding the roles of each part, users can optimize their equipment’s performance and prevent unnecessary repairs. Proper care also extends the lifespan of the tool, making it a valuable investment for long-term use.

Kuhn Rotary Rake Component Breakdown

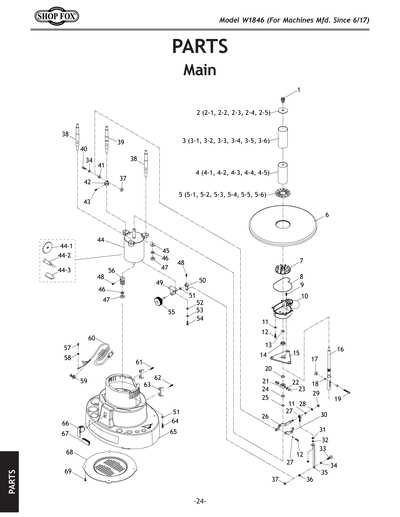

Understanding the different elements of a farm implement is essential for ensuring proper function and maintenance. By breaking down the structure of the equipment, operators can easily identify each component and understand how it contributes to the overall operation. This knowledge is key for troubleshooting, regular upkeep, and enhancing the machine’s performance.

Main Functional Units

The primary units of this agricultural tool work together to achieve efficient field work. These key sections play a role in maneuvering, guiding, and processing materials. Maintaining each unit individually helps in maximizing productivity and minimizing operational disruptions.

Critical Supportive Components

Smaller, yet equally significant, components provide support to the core units, ensuring stability and smooth movement. Proper attention to these auxiliary parts prevents premature wear and tear, allowing the tool to continue performing at its best.

Understanding the Parts of a Kuhn Rake

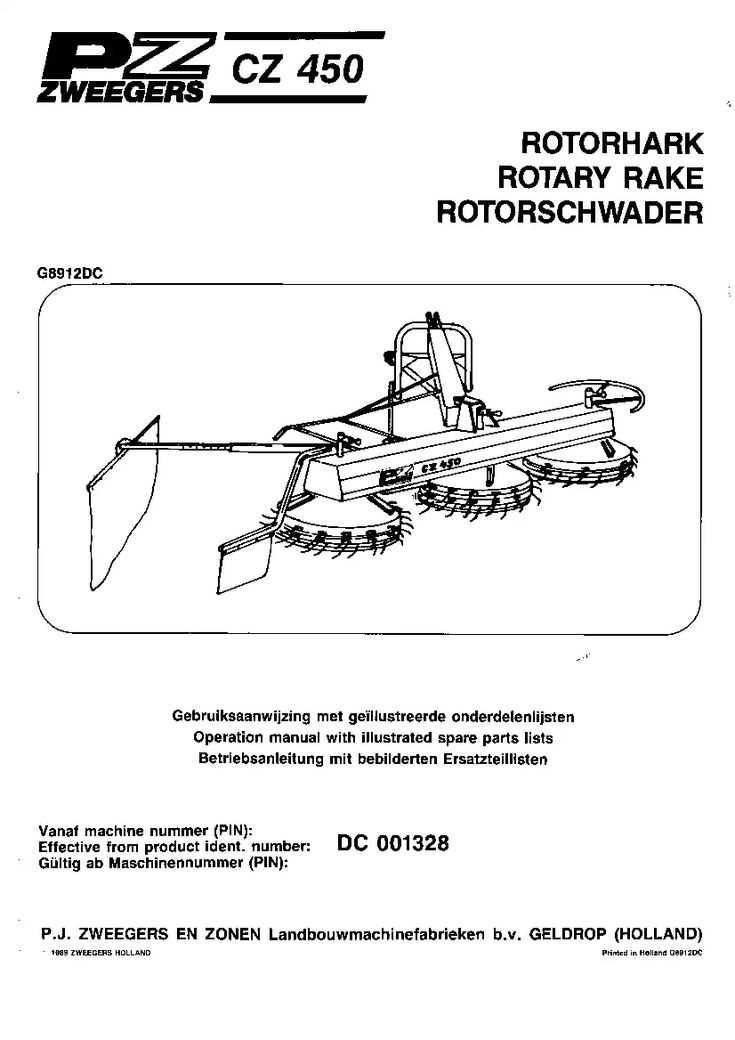

Every agricultural machine is made up of several key elements that work together to ensure effective performance. By understanding these components, operators can better manage their equipment and enhance its efficiency. This section focuses on the various sections and their functions within the tool, offering insights into how each contributes to the overall process.

Key Functional Components

The main units of the implement are designed to perform specific tasks, whether it’s handling materials, adjusting the working width, or ensuring precise movement. Each functional unit plays a vital role in the overall operation and must be properly maintained to prevent issues during use.

Supporting Structures

Smaller but essential structures support the machine’s stability and durability. These elements provide the necessary framework to allow smoother operation, protecting against wear and prolonging the life of the equipment.

Maintenance Tips for Kuhn Rake Parts

Proper upkeep of agricultural machinery ensures that it operates efficiently and lasts longer. Regular maintenance of the different sections of the equipment is vital to prevent breakdowns and reduce repair costs. In this section, we’ll highlight essential maintenance practices to keep the implement in top condition.

Routine Inspection and Cleaning

Frequent checks and thorough cleaning are the foundation of good maintenance. Inspect all critical elements for any signs of wear, damage, or debris buildup. Cleaning after each use ensures that dirt or residue doesn’t interfere with the machine’s operation, improving its performance and extending its lifespan.

Lubrication and Adjustment

Maintaining the proper lubrication levels in the moving parts helps reduce friction, preventing unnecessary wear. Regularly adjust settings to ensure the tool operates smoothly, and always follow the manufacturer’s guidelines for optimal maintenance practices.