When working with complex machinery, having a clear understanding of its various parts and how they fit together is essential for both maintenance and repair. This section provides a detailed exploration of the individual elements that make up the system, helping users identify key components and their functions.

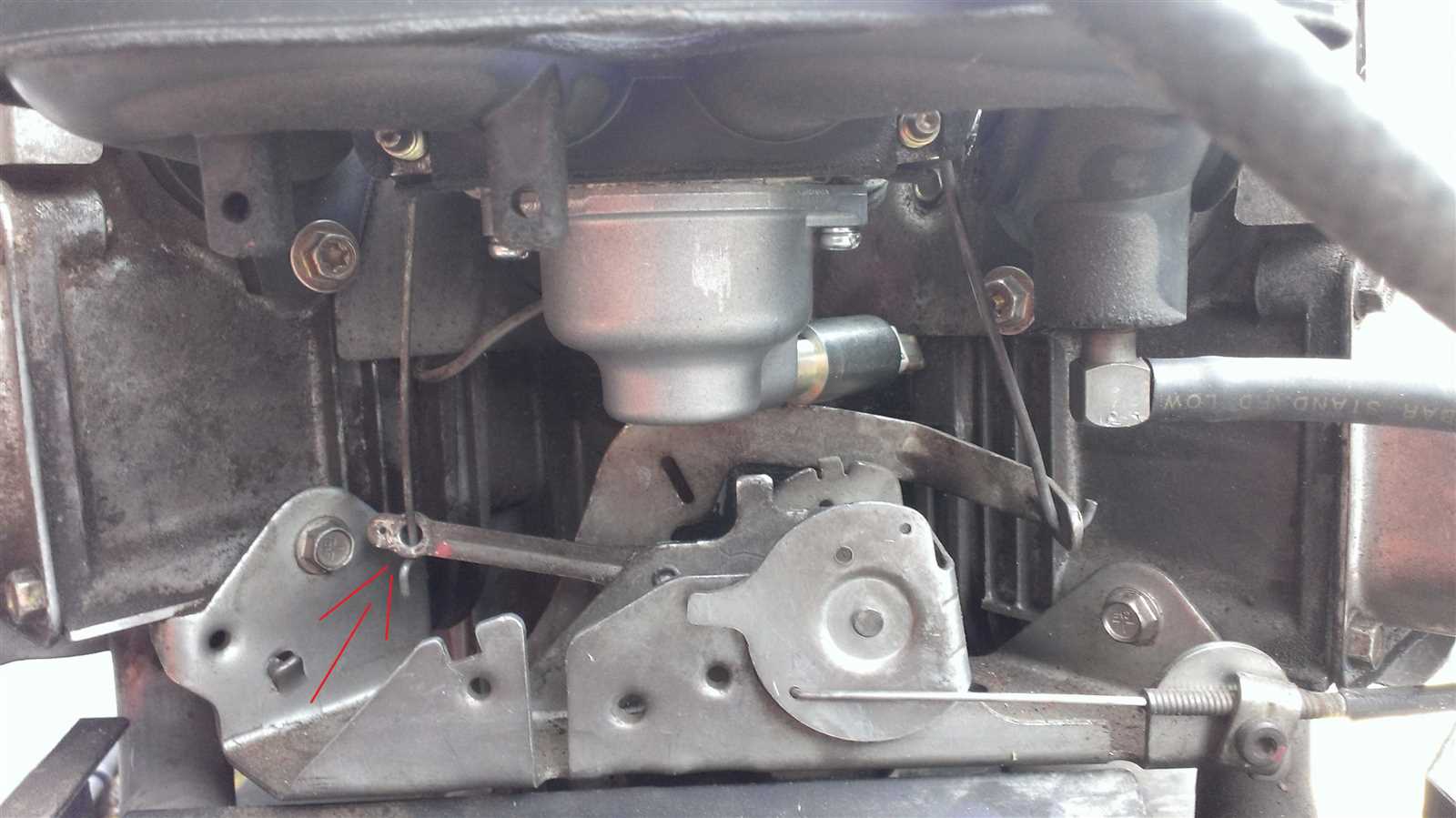

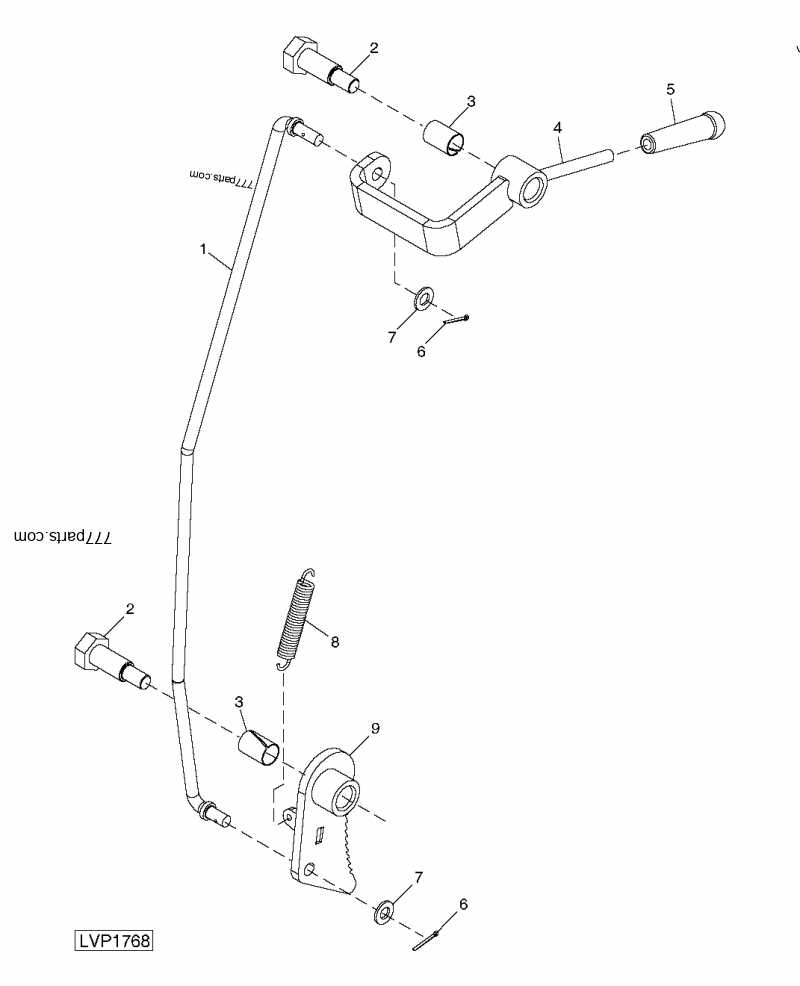

For those unfamiliar with the intricate structure, visual aids can offer significant clarity. These resources allow users to quickly grasp the relationships between different components, ensuring smooth operation and troubleshooting. Whether you are a technician or a curious enthusiast, learning about the layout of these elements can save time and reduce errors.

Efficient use of diagrams can drastically improve your approach to repairs, enabling you to focus on specific areas without unnecessary detours. By becoming familiar with the overall configuration, you’ll be able to make informed decisions that lead to better outcomes.

Understanding the System Layout

Grasping the full layout of a machine is essential for anyone looking to operate or repair it effectively. This section provides a closer look at how different elements are organized within the system, helping users better comprehend their interactions and functions.

By studying how individual components connect and work together, users can quickly pinpoint where issues might arise. A clear understanding of the overall configuration allows for more efficient maintenance and troubleshooting, minimizing downtime and avoiding unnecessary replacements.

Familiarizing yourself with the system’s structure is crucial for making informed decisions during repairs. It ensures that each element is addressed properly, contributing to optimal performance and longevity. Visual aids enhance this understanding, providing a quick reference to identify any part that may require attention.

Key Components in the System

Understanding the crucial elements of any machinery is vital for its efficient operation. Each individual component plays a specific role, contributing to the overall performance and reliability of the entire system. In this section, we will focus on some of the primary components and their functions.

Drive Mechanisms

The drive system is at the heart of the machine’s movement and functionality. It includes components that transfer energy to various parts, allowing them to work in sync. These mechanisms are essential for ensuring smooth operation and preventing unnecessary strain on other elements.

Control Elements

Control systems help manage the machine’s responses to external inputs. They consist of switches, sensors, and regulators that allow the operator to adjust settings or respond to changing conditions. Proper understanding of these control elements is key to maximizing efficiency and safety during use.

Proper maintenance of these components is crucial for extending the machine’s life. Neglecting any of these parts could result in malfunction, requiring costly repairs. Regular inspection ensures that each element is functioning correctly, helping avoid unexpected breakdowns.

How to Use the System Layout

Effectively utilizing a visual representation of a machine’s structure is a key skill for anyone involved in its maintenance or operation. These illustrations serve as a map, guiding users through the various elements and showing how they interconnect. Knowing how to read and interpret this layout can significantly streamline troubleshooting and repairs.

Identifying Key Elements

Start by familiarizing yourself with the layout of the components. Each part is labeled clearly, allowing you to quickly locate and identify it. Pay attention to the positioning of the elements as this often indicates their relationship with other components. Understanding these connections will help you understand how to address issues that arise.

Step-by-Step Troubleshooting

Once you have a basic understanding of the layout, use it to diagnose problems systematically. Follow the flow from one part to another, checking each section for potential faults. By having a clear visual map, you can avoid unnecessary disassembly and focus on the root cause of the issue more efficiently.

Regular practice with these layouts improves your ability to troubleshoot quickly and accurately. With time, interpreting the diagrams becomes second nature, leading to faster resolution of problems and better overall maintenance.