In any precision machinery setup, understanding the layout and interaction of various elements is crucial for optimal performance. The intricate system of mechanical structures ensures that each component works in harmony to achieve desired outcomes. Familiarity with how these elements are arranged and their functions can significantly improve efficiency and accuracy.

Comprehending the arrangement and functionality of essential machine components is a fundamental skill for anyone involved in the manufacturing or repair industry. Knowing how each piece contributes to the overall process helps operators make informed decisions and troubleshoot effectively when issues arise.

Mastering the visual representation of these elements is essential for anyone looking to work efficiently with complex machinery. Whether you are designing, maintaining, or operating such equipment, understanding these key features will provide a solid foundation for success in your field.

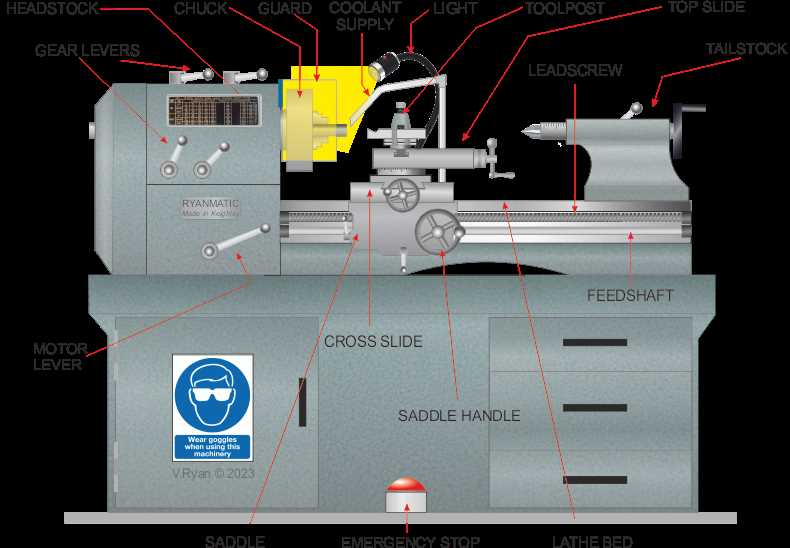

Key Components of a Lathe Diagram

Understanding the essential elements that make up a precision machinery layout is vital for anyone working with such systems. These key structures form the backbone of the entire setup, each playing a significant role in ensuring smooth operation. Mastery of these components allows for better functionality and efficiency in the machining process.

Critical Mechanical Elements

Each mechanical element serves a specific function, whether it is responsible for guiding movement, adjusting tool positions, or maintaining stability during operation. These structures work together to ensure that the machine performs accurately and efficiently. A thorough understanding of their roles helps to optimize the entire process, reducing errors and increasing productivity.

Essential Supportive Components

Supportive elements provide the necessary stability and security required for precision work. These parts may not always be directly involved in the actual machining but are crucial for ensuring the equipment runs smoothly and remains in optimal condition. Recognizing their importance is key to maintaining the overall effectiveness of the system.

Functions of Lathe Parts in Machining

The various components of a machining system each have a specific role that contributes to the overall process. These elements ensure that material is processed accurately and efficiently, with each part performing a distinct function to achieve the desired result. Understanding their roles is essential for optimizing the machining operation and preventing errors.

For instance, certain elements are designed to control the speed and direction of movement, allowing for precise cuts and adjustments. Others are responsible for holding materials firmly in place, ensuring that the workpiece remains stable throughout the process. By working together, these components create a well-coordinated system that enhances the overall performance of the machine.

Furthermore, some components assist in adjusting the tool’s position or help maintain the correct pressure, ensuring uniformity in every operation. Mastery of these functions allows operators to fine-tune the system for different tasks, making it adaptable to various machining requirements and boosting its versatility.

How to Read a Lathe Diagram Effectively

Interpreting the layout of a machining system can be challenging, but with the right approach, it becomes easier to understand how each component works together. Being able to read and analyze these layouts effectively is crucial for anyone working with machinery, whether you’re setting up, troubleshooting, or designing equipment. A clear understanding of the representation allows for better decision-making and more efficient operation.

Familiarizing with Symbols and Notations

Recognizing the different symbols and notations used in machinery illustrations is the first step toward effective interpretation. These symbols represent various mechanical elements, each with specific functions. Once familiar with the most common symbols, it becomes easier to identify the components at a glance and understand their interactions within the system.

Understanding Component Relationships

Paying attention to the relationships between different components is essential for fully understanding how the system operates. The way these elements are arranged and connected will often give insight into the flow of operation, indicating how movement, adjustments, and power are distributed. By examining these connections, one can gain a comprehensive view of the system’s functionality and potential areas for improvement.