For anyone working with optical measurement devices, a clear understanding of their inner workings is essential. Knowing the individual elements and their roles helps in troubleshooting and maintaining the equipment, ensuring it remains in optimal condition. Whether you’re a technician, optometrist, or enthusiast, familiarizing yourself with the intricate details of these devices can improve both efficiency and accuracy.

Identifying each component in your optical tools can often be the key to diagnosing issues. Regularly consulting a detailed breakdown of the components will guide you in recognizing any wear and tear, and ensure smoother repair procedures. With the right knowledge, even complex systems can be managed with ease.

Regular upkeep not only prolongs the life of your instruments but also guarantees that they provide precise readings. Understanding how different parts work together allows for effective maintenance, keeping your equipment functional for years. This expertise is invaluable, especially in environments that demand high levels of performance and precision.

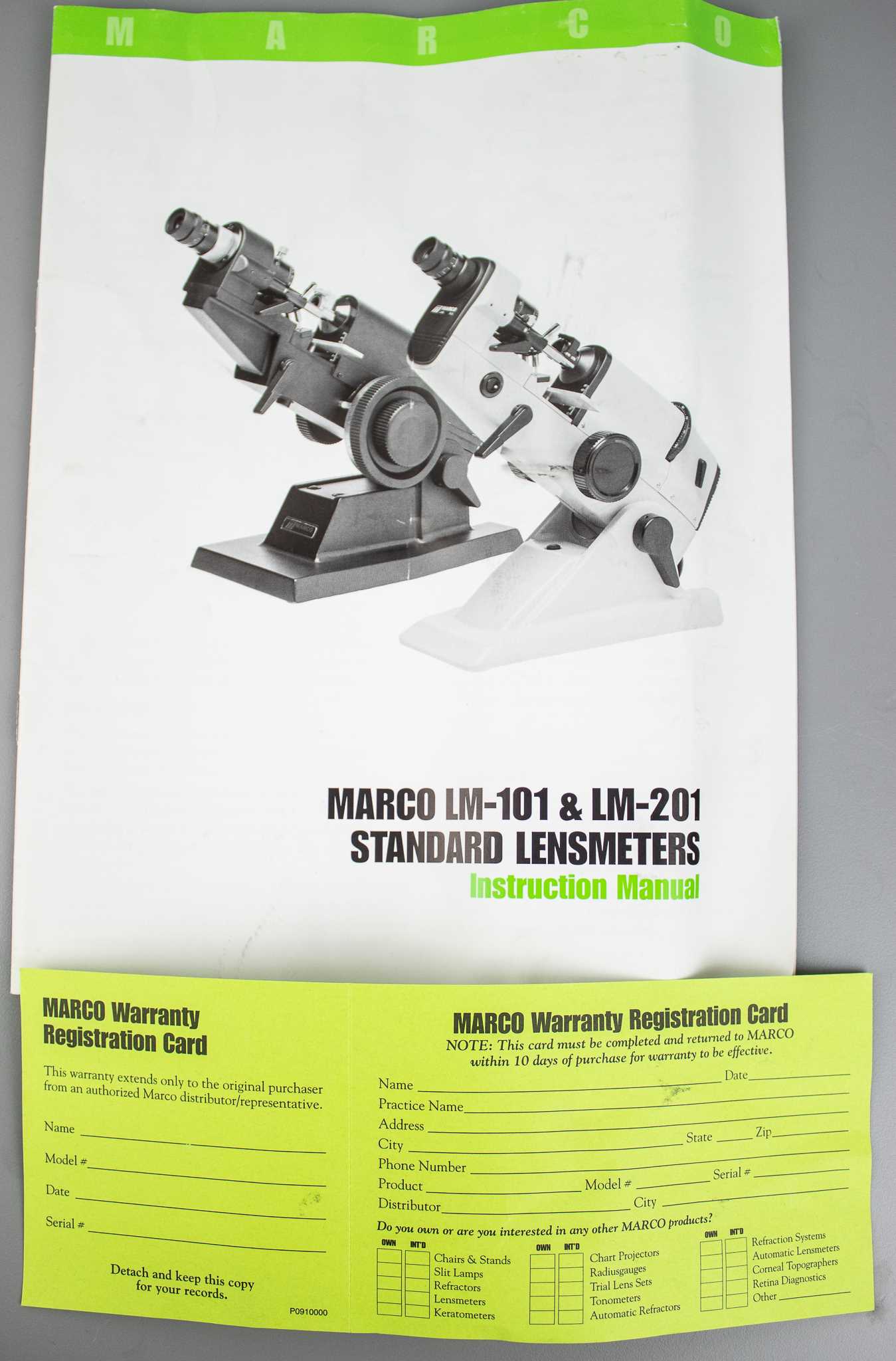

Understanding the Optical Instrument Components

To effectively use any optical measurement device, it’s essential to understand how its individual components interact. Each element plays a vital role in ensuring the system functions correctly and provides accurate readings. From the calibration settings to the mechanical adjustments, knowing the purpose of each part enhances your ability to maintain and repair the instrument when needed.

The primary components typically consist of mechanical, optical, and electronic elements that work together seamlessly. For instance, the alignment system is crucial for ensuring accurate measurements, while the lenses and mirrors are responsible for focusing and directing light. Understanding how each piece contributes to the overall functionality will allow you to diagnose issues and perform regular maintenance.

Regular inspection of these components is key to extending the life of your equipment. Proper handling and timely adjustments can prevent misalignments or inaccuracies in readings. Whether dealing with the delicate optical lenses or the robust mechanical housing, recognizing the importance of each component is fundamental to keeping your tools in peak condition.

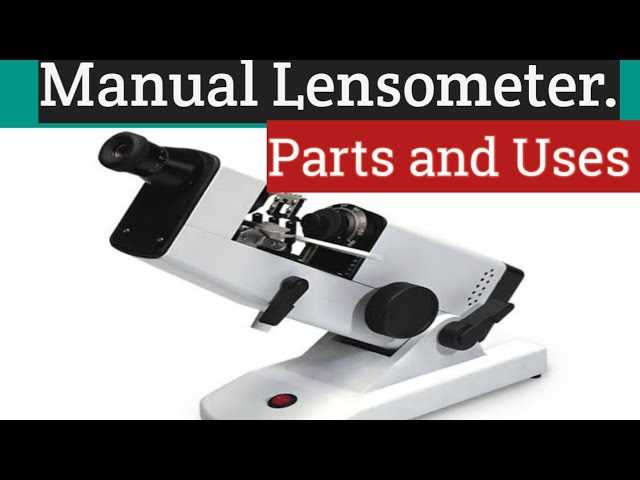

How to Read an Optical Instrument Breakdown

Understanding the layout of an optical device’s internal structure is crucial for maintenance and repair. A well-detailed schematic offers a clear representation of how each component is arranged and interconnected. By learning to read such a breakdown, you can easily identify individual elements and their functions, making it easier to troubleshoot or perform necessary adjustments.

The key to reading these schematics is to focus on the labels and symbols used to represent each part. Components are typically outlined with clear markings indicating their size, position, and relationship to other elements. Recognizing the different sections of the layout, such as mechanical or optical parts, will guide you in understanding the flow of the system.

Paying attention to color codes and annotations in the breakdown is equally important. These details often provide information on specific configurations or required adjustments. A thorough understanding of the breakdown will make it simpler to follow instructions for repair or modification, allowing for more efficient work and better results in the long run.

Common Optical Instrument Repairs and Maintenance

Maintaining and repairing optical measurement devices is essential to ensure they function properly over time. Regular care prevents breakdowns and ensures accurate readings. Simple tasks like cleaning lenses, tightening screws, and calibrating the system can prolong the life of your equipment. Knowing what common issues to look out for and how to address them will save both time and money.

Cleaning and Calibration

One of the most frequent tasks in maintenance is keeping the lenses free from dust, smudges, and other contaminants. A proper cleaning routine will prevent inaccuracies and help preserve the clarity of your readings. Calibration is equally important, as the device may lose accuracy over time. Ensuring that all settings are aligned correctly is crucial for precise measurement.

Identifying and Fixing Mechanical Issues

Another common repair involves addressing mechanical issues, such as misaligned components or faulty adjustments. Over time, wear and tear can cause certain parts to shift or become loose. Regularly checking the device’s structure and ensuring that all moving parts are functioning smoothly will help avoid more serious breakdowns and maintain optimal performance.