When working with complex machinery, knowing the individual elements and how they function together is crucial. Understanding each component’s role and how they fit into the overall system allows for better maintenance, efficient repairs, and smoother operation.

This guide will help you navigate the various components of your equipment, showing you how to interpret the schematics and identify key pieces that play an essential role in its functionality. Accurate identification of each part ensures you can address any issues quickly and keep everything running efficiently.

Whether you’re troubleshooting or performing regular maintenance, understanding how the components interact is a vital step. By following the diagram closely, you’ll be able to enhance the longevity and performance of your equipment, avoiding costly repairs in the future.

Understanding the Equipment Components

Every piece of machinery is composed of various elements, each contributing to the system’s overall performance. By becoming familiar with these individual components, you gain a clearer understanding of how the entire system operates, how to maintain it, and how to troubleshoot effectively when issues arise.

Key Elements in the System

The main elements include pumps, hoses, valves, and nozzles. Each plays a specific role, whether it’s directing the flow, controlling the pressure, or ensuring a consistent output. Knowing the function of each part helps in identifying any malfunctions quickly, allowing for timely adjustments and repairs.

How Components Interact

The effectiveness of the system relies on how well these parts work together. Understanding the relationship between pressure regulation, fluid flow, and output ensures that adjustments made to one part don’t negatively impact others. A well-maintained system allows for more precise operations and reduces wear and tear over time.

How to Read the Equipment Schematic

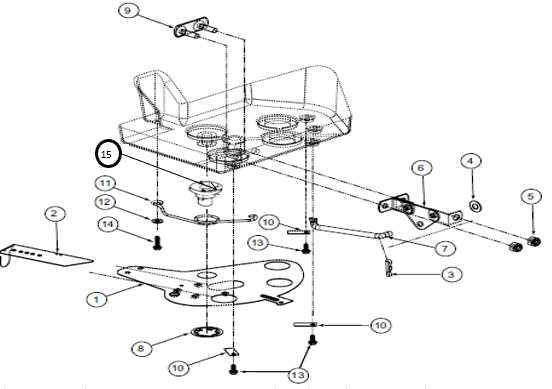

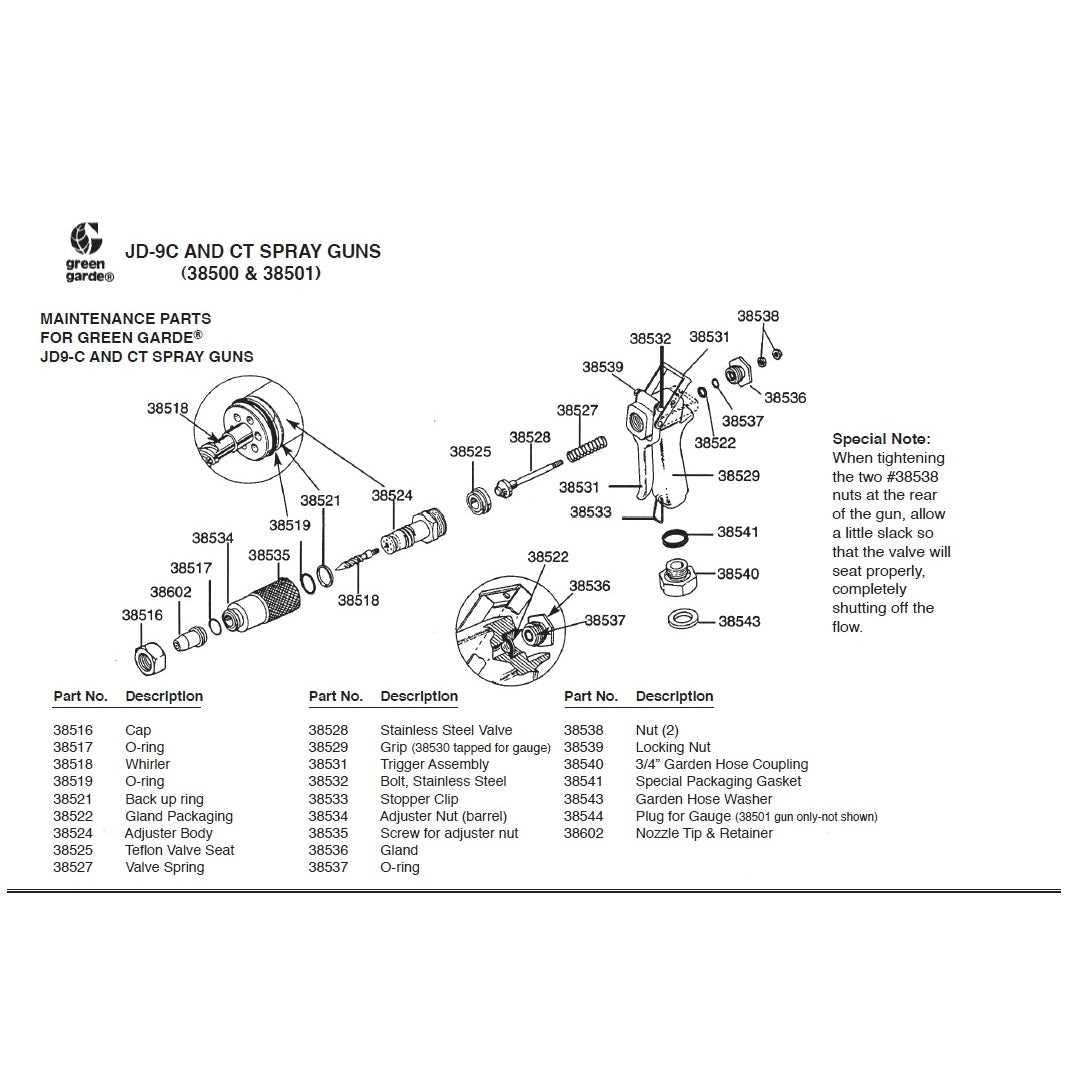

Interpreting a schematic is essential for understanding the relationship between different components within a system. These visual representations provide an organized way to identify and locate each element, making repairs and maintenance more straightforward. By familiarizing yourself with the layout and symbols, you can efficiently navigate through the blueprint and pinpoint the necessary parts.

First, focus on the labels and references. These will indicate the part numbers and corresponding descriptions. Understanding these codes will allow you to find the exact components in any documentation or replacement catalogs. Additionally, pay attention to the lines and connections, as they illustrate how parts interact with each other.

Another key aspect is identifying groups of parts that function together. Some schematics highlight these sections with a different color or shaded area. Recognizing these groups will help you focus on specific sections during troubleshooting or assembly, saving time and effort in the process.

Common Issues and Troubleshooting Tips

Equipment can sometimes experience performance issues due to wear, blockages, or component failures. Being able to identify and address these common problems is crucial for keeping the system running smoothly. Knowing what to look for can save time and prevent further damage.

Low Pressure or Uneven Output

If the output is inconsistent or the pressure is lower than usual, the issue could lie in a clogged filter, damaged hose, or malfunctioning valve. Inspecting the hoses for cracks or leaks is essential. Ensure that all filters are clean, and valves are properly adjusted to ensure smooth flow.

Leaking Fluids

Leaking can occur if seals or connections are worn out or improperly tightened. Check for any visible signs of fluid escaping from joints or valves. Re-tightening connections or replacing faulty seals will typically resolve the issue. In more severe cases, component replacement may be necessary.