Understanding the various elements that make up your model train is crucial for effective maintenance and repair. Each system is made up of multiple pieces that work in harmony, and knowing how they fit together can simplify troubleshooting and restoration tasks. Whether you’re a beginner or an experienced enthusiast, having a clear visual reference and a detailed breakdown of components can significantly enhance your ability to care for your collection.

When it comes to fixing or upgrading your model train, visual guides can be invaluable. These resources allow you to see the precise configuration of each element, helping you identify what needs attention. With the right approach, repairing or replacing individual parts becomes a manageable task, allowing you to enjoy your hobby without the frustration of confusion or delay.

Understanding Lionel Parts and Components

To properly maintain your model train system, it’s essential to understand the various elements that work together to create its functionality. Each train is composed of a variety of distinct pieces, each with a specific role in the overall operation. Familiarizing yourself with these components can help you troubleshoot, repair, and even enhance the performance of your collection.

Key Components of a Model Train

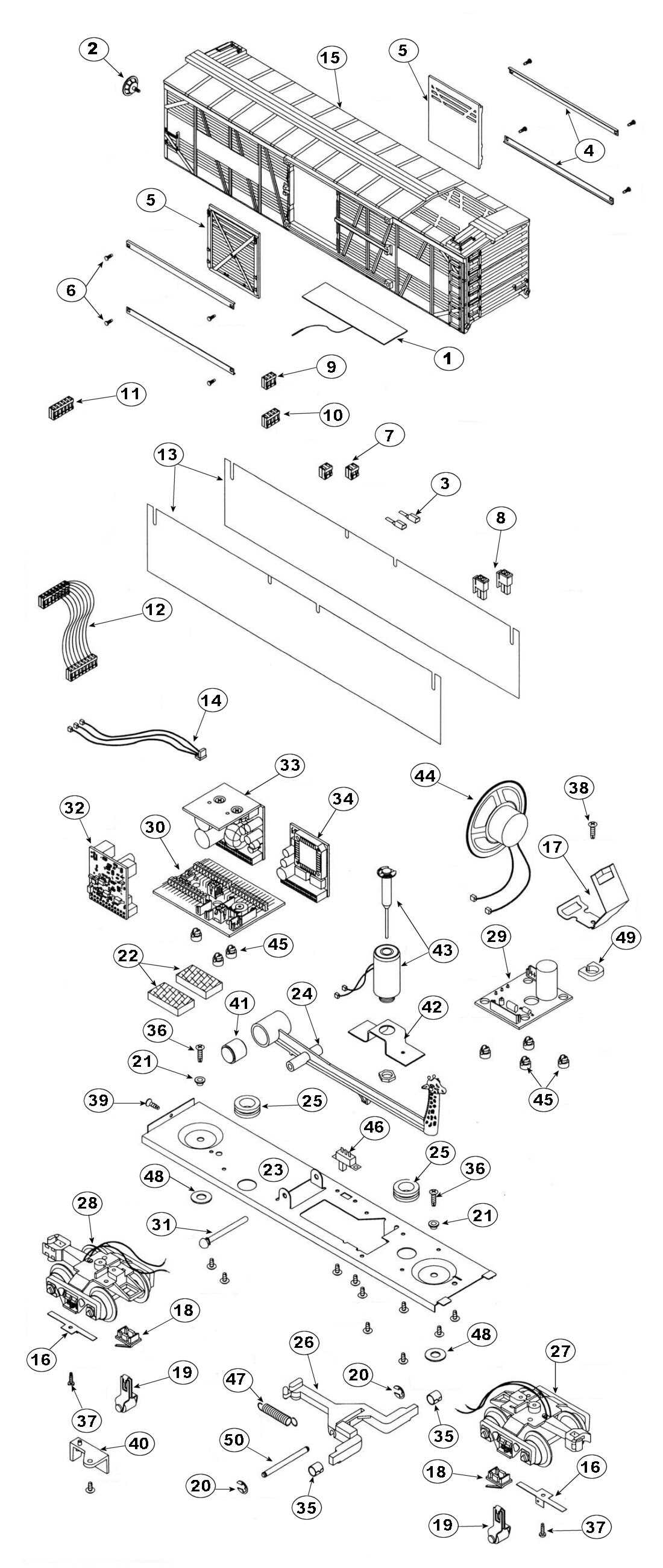

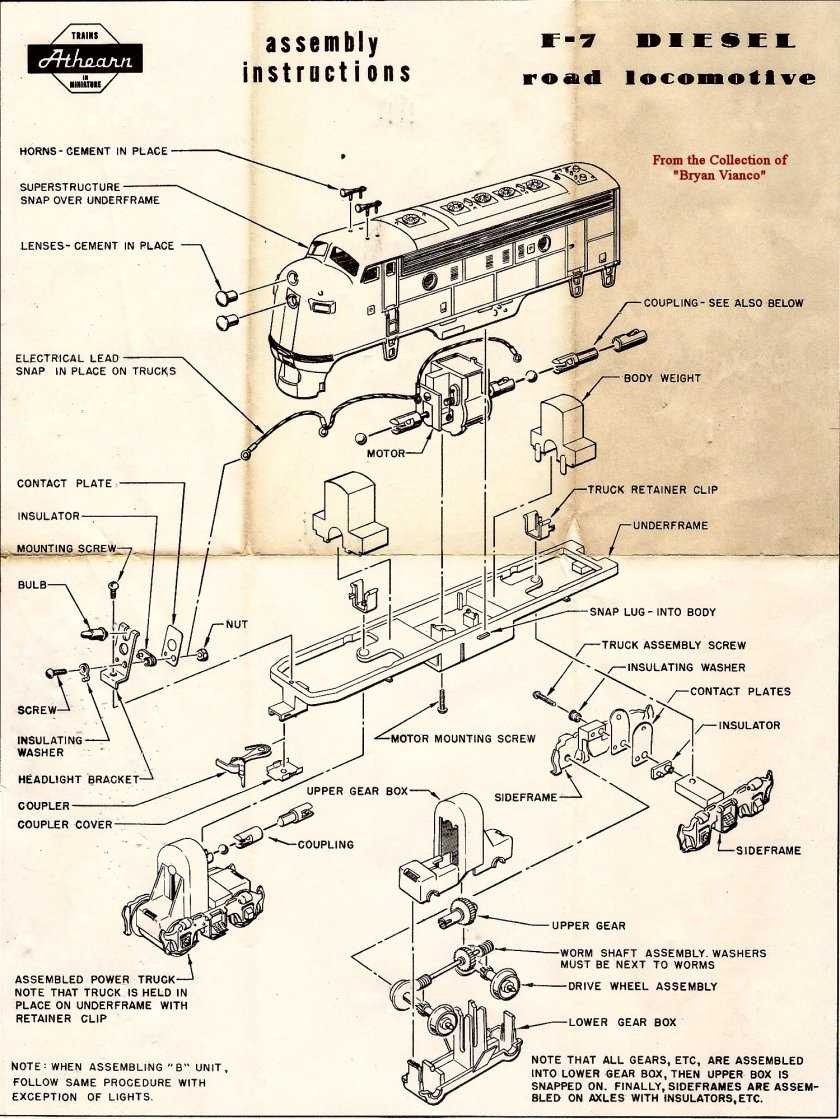

The core structure of any train consists of several major components, such as the chassis, wheels, motors, and electrical systems. These elements are responsible for movement, power distribution, and the smooth operation of the train on its track. Understanding the interaction between these elements allows you to identify potential issues, from a motor malfunction to wheel misalignment, ensuring that you can resolve any problems efficiently.

Additional Accessories and Their Functions

In addition to the main functional components, model trains often include various accessories that enhance the experience, such as couplers, lighting systems, and sound modules. Each of these accessories adds a layer of realism and interactivity. By understanding how these supplementary pieces integrate with the primary components, you can expand your system and make informed decisions about upgrades or repairs.

How to Read Exploded Diagrams for Repairs

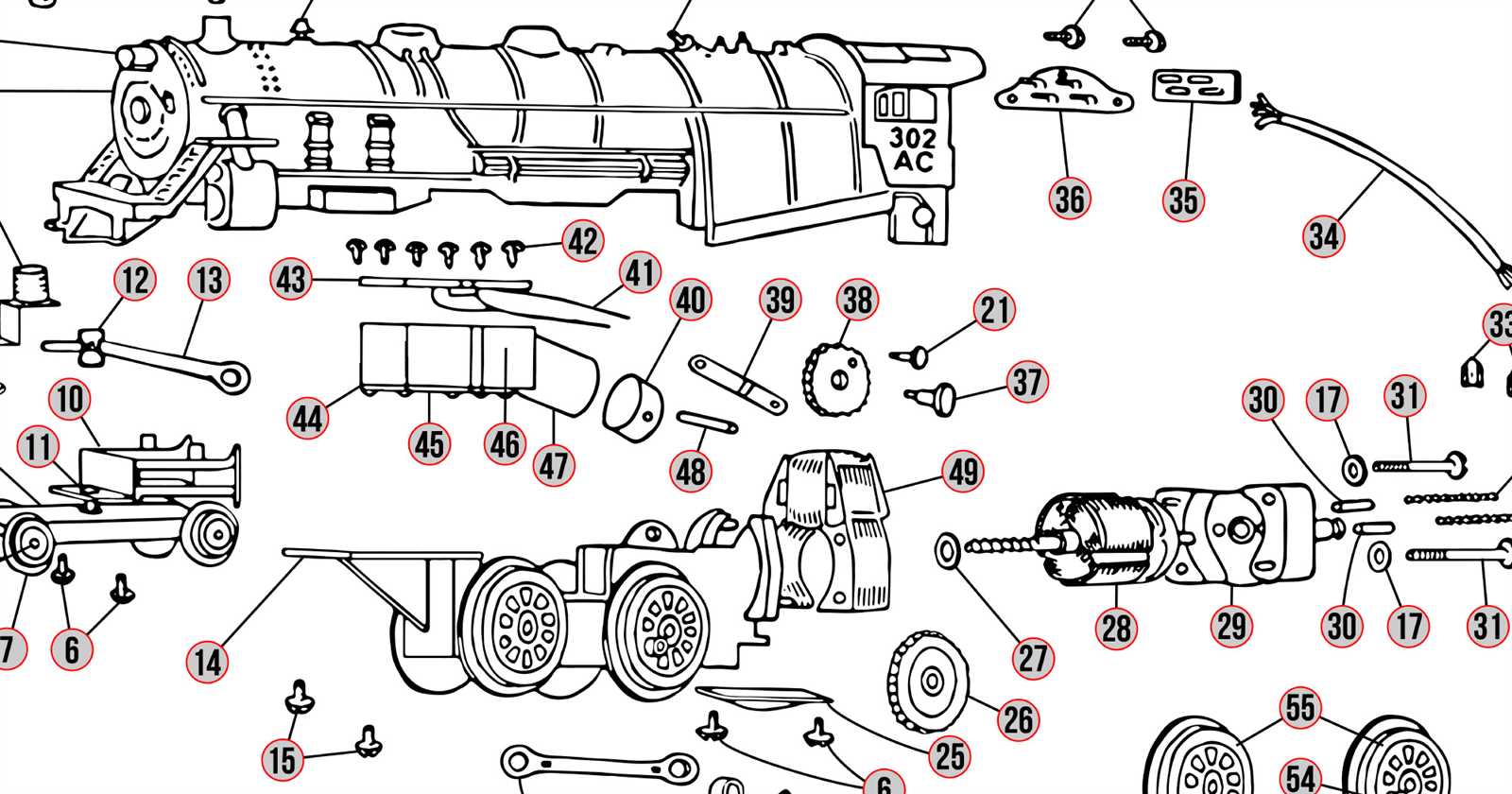

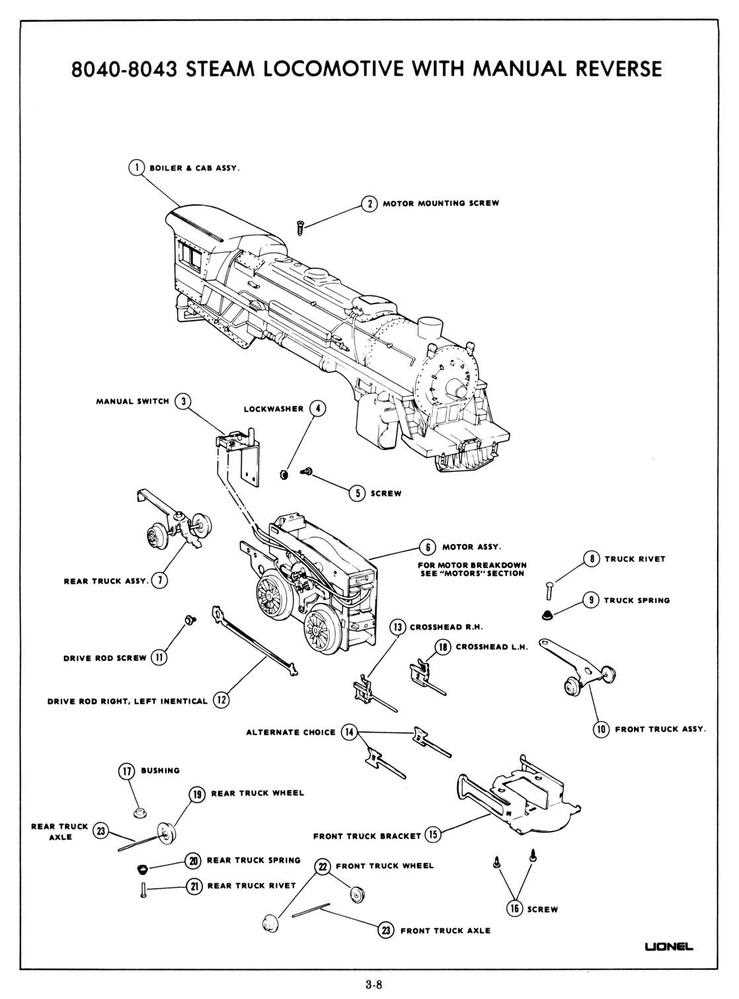

When performing repairs on your model train, a visual guide showing the relationship between each individual component is invaluable. These illustrations provide a detailed view of how the various pieces fit together, allowing you to understand their arrangement and the role each plays in the system. By following these detailed images, you can identify damaged or worn parts quickly and ensure a more precise repair process.

Identifying Components and Their Positions

The first step in understanding these visual aids is recognizing the symbols and markings used to represent different parts. Typically, each element is numbered or labeled, indicating its exact position within the assembly. Paying attention to these labels is crucial, as it helps you follow the correct order during disassembly or reassembly, minimizing the risk of errors.

Using the Guide for Troubleshooting

These illustrations also serve as an excellent tool for diagnosing issues. By comparing the condition of your train with the diagram, you can easily pinpoint areas that may be causing performance issues. For example, if a motor isn’t functioning correctly, the diagram can help you trace the electrical connections and identify potential faults. This approach allows for targeted troubleshooting and ensures that repairs are both effective and efficient.

Common Lionel Train Parts and Their Functions

Every model train system consists of several essential components, each with a specific role in ensuring smooth operation. Understanding how these key elements function can help you maintain and repair your train effectively. From power distribution to movement control, each part plays a crucial part in the overall performance of your model train setup.

Main Drive Mechanism

The motor serves as the heart of the system, converting electrical energy into mechanical power that drives the train forward. It is typically connected to the wheels via a series of gears, allowing the train to move smoothly along the track. If the motor fails or experiences reduced performance, it can significantly affect the functionality of the entire system.

Track Connection Components

The wheels and couplers are vital for ensuring proper movement and stability. The wheels allow the train to stay on track and move forward, while the couplers are responsible for connecting individual cars to the locomotive. A malfunction in either of these can cause derailments or affect the train’s ability to connect to additional cars, disrupting the entire operation.