For anyone who owns a garden tool with a rotating mechanism, knowing the individual parts and their functions is crucial for proper upkeep. Each component plays a vital role in ensuring smooth operation and longevity. Understanding these elements helps in identifying issues early, making repairs more efficient, and enhancing overall performance.

By familiarizing yourself with the breakdown of essential pieces and how they interact, you can quickly pinpoint any wear or damage. This knowledge simplifies maintenance tasks and reduces the need for professional repairs. It also empowers you to make the most out of your equipment, ensuring its reliability during every use.

Proper care and attention to these parts can extend the life of your machine. Regular inspection and timely replacements will not only maintain its functionality but also help avoid more expensive fixes in the future. With a clear understanding of each piece, keeping your machine in top condition becomes much more manageable.

Understanding Mantis 20 Tiller Components

Every mechanical tool relies on several key elements working in harmony to achieve optimal performance. Understanding how each individual component functions and interacts with others is essential for ensuring efficiency and reliability. When one piece fails or becomes damaged, it can affect the entire operation, so recognizing each part’s role is important for maintenance and troubleshooting.

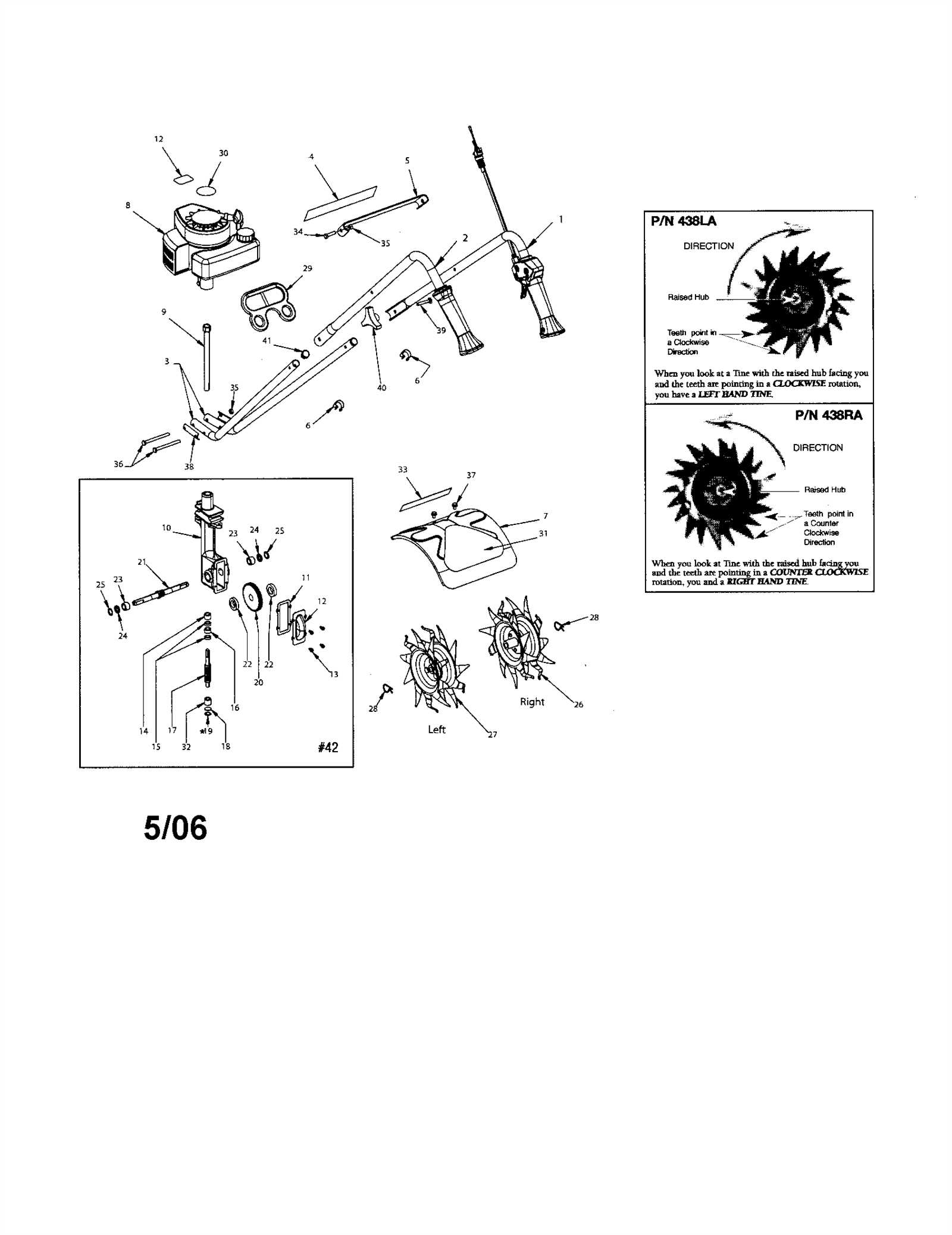

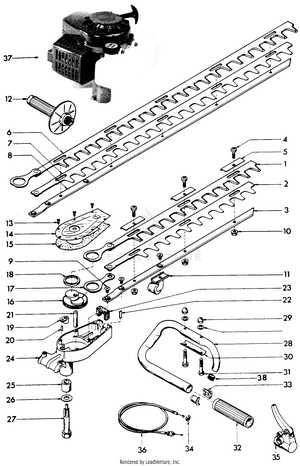

In this context, the equipment consists of various interconnected systems, each responsible for specific tasks. These include the engine, rotating mechanism, and support structure, among others. Each element has a distinct purpose, such as providing power, movement, or stability, and requires attention to detail when performing regular checks or repairs.

Familiarizing yourself with the layout of these systems allows for quicker identification of issues and a better understanding of how they function together. Knowing which components need periodic maintenance and which are more prone to wear ensures that the machine will operate smoothly for longer periods. Proper knowledge of these parts empowers you to extend the lifespan of the tool and maintain its peak performance throughout its use.

How to Identify Mantis 20 Parts

Being able to recognize and distinguish each component of your equipment is crucial for effective maintenance and repair. When issues arise, identifying the specific element causing the problem can save time and effort. Familiarizing yourself with the various pieces and their locations will make diagnosing malfunctions much easier.

Start by reviewing the system layout, focusing on the key sections that are most prone to wear. For example, the engine, transmission, and handle mechanisms often require the most attention. By understanding their function, you can quickly pinpoint which part may need replacing or servicing.

Using visual aids, such as detailed images or illustrations, can further help in recognizing specific elements. These resources provide a clear reference, making it simpler to match the parts with their real counterparts. Additionally, manufacturers often include labels or part numbers on components, which can be helpful when looking for replacements.

Maintaining Your Mantis 20 Tiller

Proper upkeep is essential to ensure your gardening tool operates smoothly and lasts for years. Regular maintenance helps prevent unexpected breakdowns and ensures all mechanisms function as intended. By staying on top of routine tasks, you can address minor issues before they turn into major repairs.

Begin by checking the most frequently used components, such as the engine and drive system. Cleaning these parts regularly and replacing any worn-out elements will keep the machine running efficiently. Additionally, ensure that moving parts are well-lubricated and free from dirt or debris that could cause damage over time.

Regular inspections of the framework and structural components will also help identify any potential weaknesses. Tighten any loose bolts or fasteners and look for signs of wear or corrosion. A small amount of care goes a long way in preserving your tool’s performance and extending its lifespan.