Understanding the intricate details of a tractor’s mechanical system is crucial for effective maintenance and repair. With numerous parts working in harmony, knowing each component’s role ensures longevity and optimal performance.

Accurate identification of these components plays a key role in troubleshooting issues. A well-detailed layout can help mechanics and owners alike to pinpoint malfunctioning areas quickly and with precision.

Proper guidance on component arrangement and common failure points enhances the ability to manage replacements efficiently, minimizing downtime and avoiding costly repairs. This guide will simplify the process and help in making informed decisions when handling machinery repairs.

Understanding Tractor Components

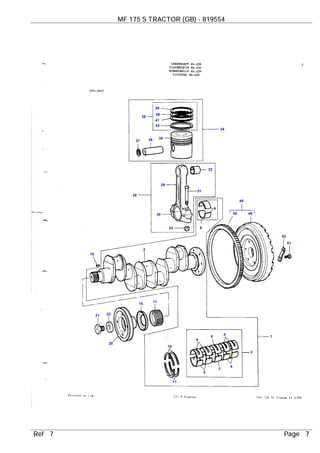

The internal mechanics of agricultural machinery consist of various interconnected elements, each designed to serve a specific function. These components work together to ensure smooth operation and prevent mechanical failures. Familiarity with the overall layout of these systems is essential for proper maintenance and repair.

From the engine to the transmission, every part plays a vital role in the tractor’s performance. Understanding the configuration and function of each element allows users to troubleshoot problems more effectively and carry out repairs with confidence. Regular inspection and knowledge of the machine’s structure can significantly extend its lifespan.

For those involved in repairs or upgrades, recognizing how components interact within the system is fundamental. This knowledge ensures that parts are replaced accurately and in the right sequence, reducing the risk of further damage or inefficiencies. Knowing the key areas where wear and tear commonly occur can help in planning maintenance tasks and avoiding unexpected breakdowns.

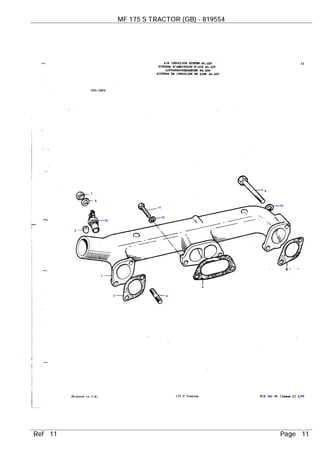

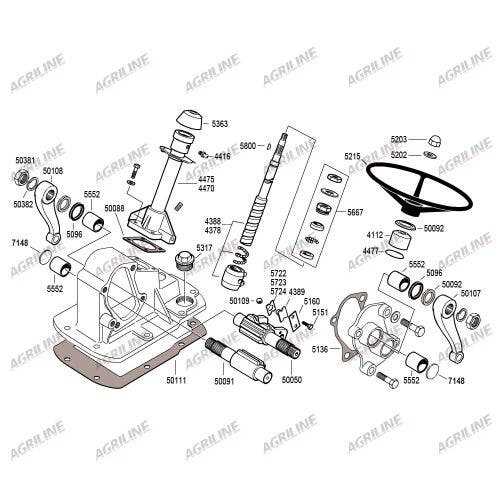

How to Read the Parts Layout

Understanding the visual representation of machinery components is crucial for anyone involved in repairs or maintenance. These visual guides serve as a roadmap, showing how different elements of the system are arranged and connected. Knowing how to interpret these layouts can simplify troubleshooting and part replacement tasks.

Identifying Key Elements

Each component in the visual guide is typically numbered or labeled for easy identification. These numbers correspond to a parts list or catalog that provides detailed descriptions and specifications for each item. Familiarizing yourself with the numbering system allows for quick identification and ensures the correct parts are selected during repairs.

Understanding Connections and Flow

In addition to showing individual components, these layouts also illustrate how parts interact with each other. Understanding the flow of energy, power, and materials within the system can help identify potential issues and understand the function of each part. Observing the arrangement helps technicians understand the relationships between parts and predict how failure in one area might affect the whole system.

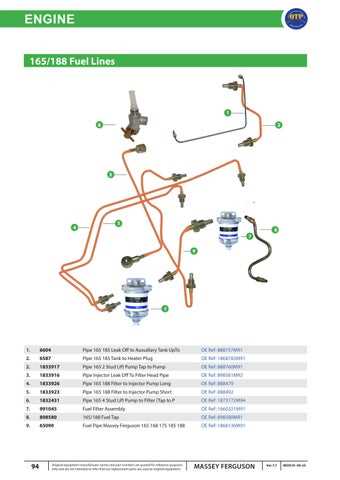

Common Issues and Replacement Parts

Every piece of machinery experiences wear and tear over time, leading to various mechanical issues. Understanding the most common problems and knowing which components typically need replacement can help in planning effective maintenance. Proactive identification of these issues can minimize downtime and extend the lifespan of the equipment.

Frequent Failures and Troubleshooting

Some common failures include issues with the engine, transmission, and hydraulic systems. These components are under constant stress during operation, leading to potential overheating, leaks, or general malfunction. Identifying early signs of wear, such as unusual noises or reduced performance, can help prevent major breakdowns and reduce repair costs.

Essential Components for Replacement

When it comes to replacements, certain elements tend to wear out more quickly than others. Gaskets, seals, filters, and belts are some of the most commonly replaced parts. Regular inspection and replacement of these critical components help maintain optimal performance and prevent more costly repairs down the line. Knowing which parts need to be replaced periodically ensures the machinery operates smoothly and efficiently.