When it comes to maintaining and repairing farm equipment, having a clear understanding of its inner workings is crucial. Every machine consists of multiple components that need regular checks to ensure optimal performance. Whether you’re an experienced mechanic or a novice, knowing how to identify and manage these elements is key to prolonging the lifespan of your tractor.

In this guide, we will explore the layout and organization of key components of your vehicle. With the right tools and knowledge, you can efficiently address issues and keep your machinery running smoothly. Learning how to interpret technical illustrations can greatly simplify the repair process, making maintenance more accessible and manageable.

Massey Ferguson 231S Overview

This type of agricultural machinery is designed to handle a variety of tasks on farms, from plowing to harvesting. The tractor is built to withstand harsh environments while offering high efficiency and reliability. It is an essential tool for many farm operators who rely on its versatile capabilities for daily operations.

Engine and Performance Features

The engine of this vehicle is known for its robust power output, ensuring that it can tackle heavy-duty tasks with ease. Equipped with a reliable transmission system, it delivers smooth power transfer to the wheels, providing consistent traction and speed. This allows for effective handling of diverse farming tasks, including working on different terrains.

Durability and Maintenance

Built with a focus on longevity, this machine can endure demanding conditions without frequent breakdowns. Regular inspections and basic maintenance routines, such as oil changes and filter checks, are essential to keeping the tractor in top shape. Understanding the key components that require attention will help extend the operational life of the equipment, ensuring it continues to function efficiently season after season.

Essential Components for Maintenance

Proper upkeep of any agricultural machine relies on understanding the vital components that require regular attention. These key elements ensure the machinery continues to operate at peak efficiency, reducing the risk of unexpected breakdowns. By familiarizing yourself with these components, you can identify issues early and prevent costly repairs.

Engine and Fuel System

The engine is the heart of any tractor, and its performance is directly tied to its maintenance. Regular checks of the fuel system, including the fuel filter and injectors, are essential for smooth engine operation. Cleaning the fuel lines and ensuring they are free from debris will help maintain optimal combustion and prevent damage to the engine over time.

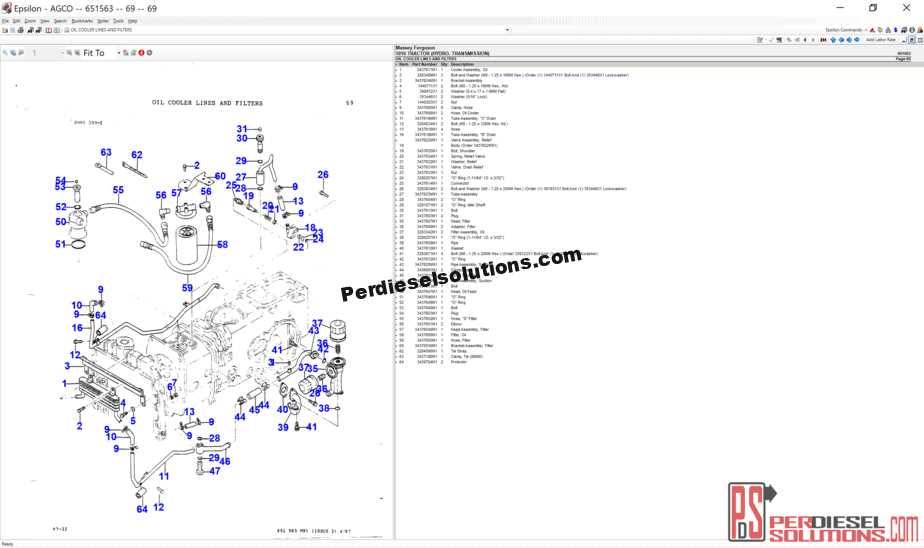

Hydraulic System

The hydraulic system plays a crucial role in the functionality of various attachments and implements. Regular monitoring of fluid levels and the condition of the hoses, pumps, and valves is necessary to avoid leaks or malfunctions. Keeping this system well-maintained ensures smooth operation of lifting equipment and other accessories, improving the tractor’s overall performance.

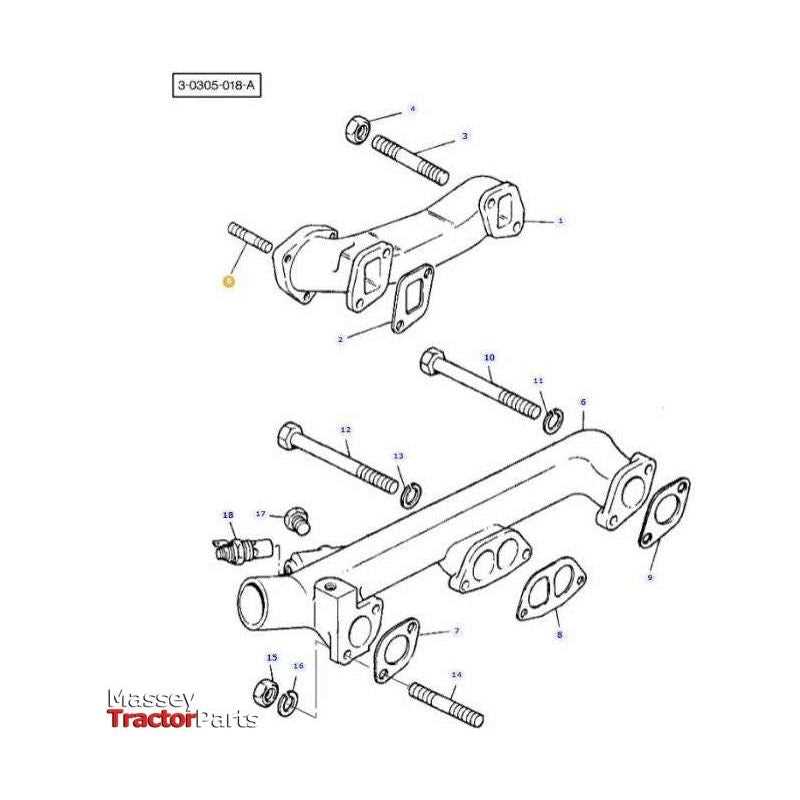

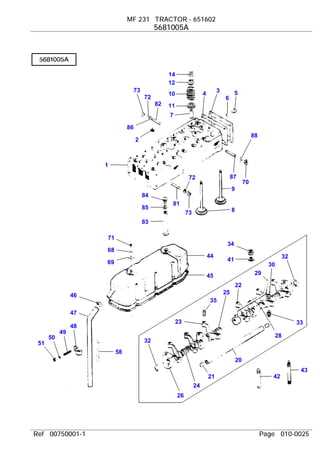

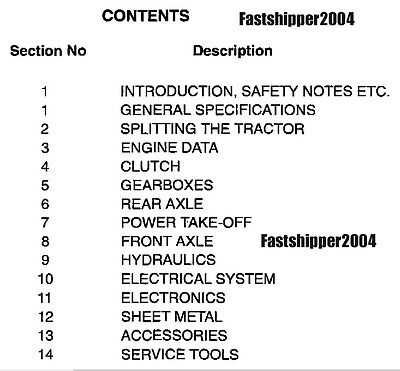

How to Read Parts Diagrams Effectively

Understanding technical illustrations is essential for anyone involved in maintaining or repairing machinery. These visual guides provide a clear view of the components, showing their relationships and how they fit together. By learning how to interpret these drawings, you can quickly identify the necessary parts, troubleshoot issues, and perform repairs efficiently.

The key to reading these visuals effectively lies in recognizing the symbols and labels used to identify each part. Pay close attention to the numbering system, which often corresponds to a list of components, and note the lines that indicate connections or assembly sequences. Understanding these elements will allow you to follow the diagram step by step, making maintenance tasks more manageable.