When maintaining heavy machinery, understanding how each element works together is crucial. A clear overview of the internal structure helps identify necessary replacements or repairs quickly, ensuring efficient operation. Familiarizing yourself with detailed breakdowns can save time and reduce costly repairs.

Whether you are a professional mechanic or a passionate hobbyist, having access to an accurate visual reference for your equipment is indispensable. These guides highlight every individual piece, giving you insight into its role and how it fits within the larger system. With the right reference in hand, diagnosing issues becomes significantly easier.

Being prepared with a reliable resource for component identification empowers you to tackle various repair challenges with confidence. Understanding how each section interrelates allows you to better plan for future maintenance and increases the lifespan of your machinery.

Understanding Tractor Components

Every piece of machinery is composed of a variety of components that work in unison to achieve optimal performance. For any vehicle, especially agricultural machines, understanding the structure and function of each part is essential for smooth operation and efficient troubleshooting. By identifying the key elements and how they interact, operators can make informed decisions about maintenance and repairs.

Key Elements of the Machine

At the heart of any tractor are essential systems such as the engine, transmission, and suspension. Each component plays a vital role in ensuring that the machine can perform the tasks required of it. The engine, for example, is responsible for generating the power necessary for movement, while the transmission transfers that power to the wheels or implements. Understanding how these systems integrate helps operators diagnose issues more effectively and maintain their equipment over time.

Maintenance and Troubleshooting

Knowing the various components of the machine also allows for better management of regular maintenance. Regular checks on essential parts, such as filters, belts, and hydraulic systems, can prevent unexpected breakdowns and prolong the lifespan of the equipment. In case of malfunction, understanding where specific components are located can aid in pinpointing the problem faster, reducing downtime and ensuring that the machine remains productive.

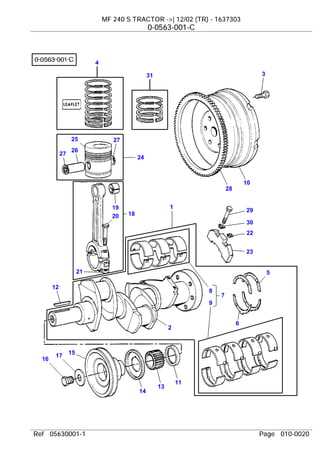

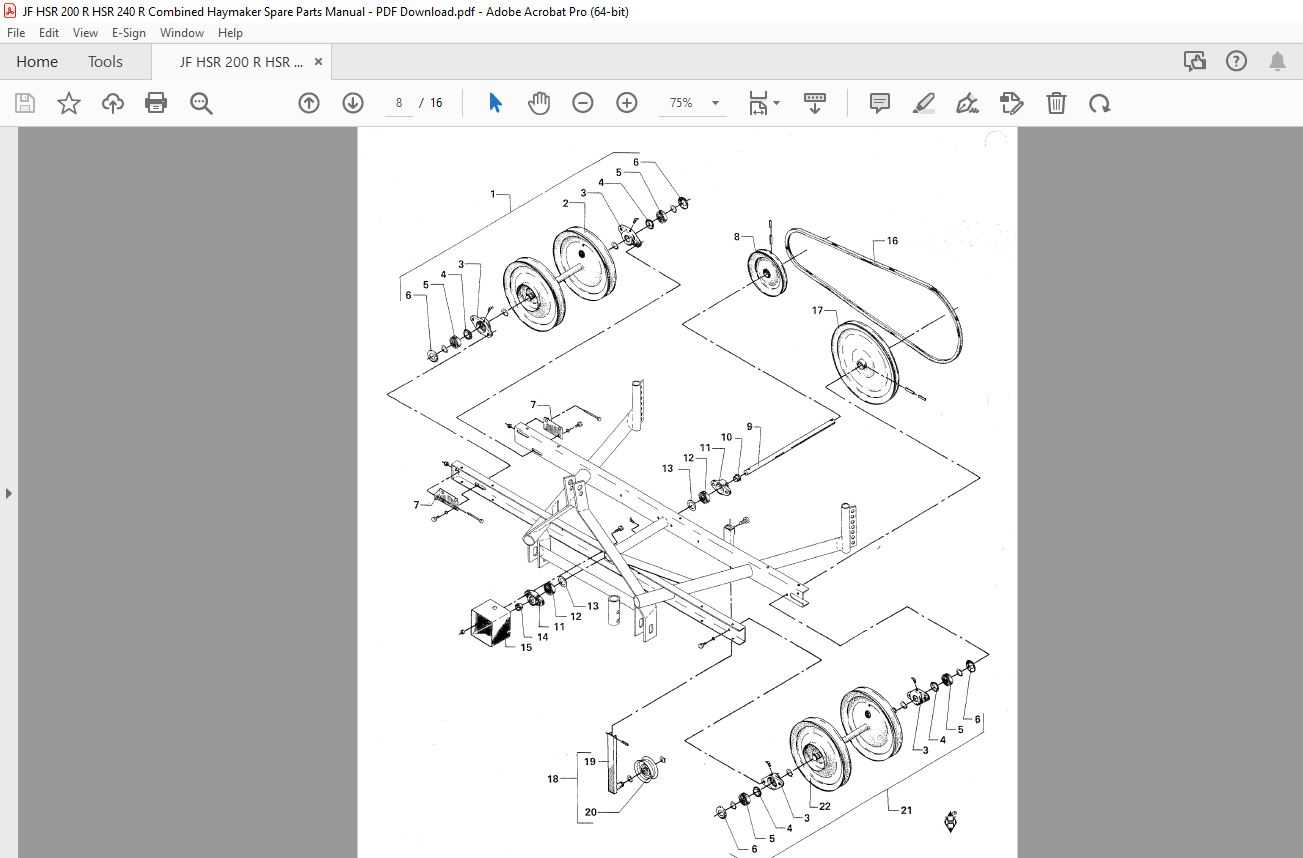

How to Read the Parts Breakdown

Understanding how to interpret a breakdown of a machine’s components is crucial for proper maintenance and repairs. These visual references provide a clear view of all the individual elements that make up a piece of equipment, helping you identify and address any issues that may arise. Knowing how to navigate these resources can save time and effort when performing repairs or replacements.

Identifying Components

Each component is typically represented by a unique number or label, allowing you to easily locate it within the system. By matching these numbers with a corresponding list, you can quickly identify the specific part that needs attention. Some diagrams also include additional details, such as sizes, shapes, and part variations, which further help with selecting the right replacement.

Understanding Connections and Function

Beyond identifying individual components, these diagrams also highlight how parts are connected and interact with each other. Understanding these relationships is vital when troubleshooting, as it enables you to pinpoint the source of the issue more effectively. By visualizing the system as a whole, you can track the flow of power or fluids, which aids in diagnosing problems more precisely.

Common Issues and Replacement Parts

Every machine, regardless of its make or model, will experience wear and tear over time. Identifying common issues early and knowing which components to replace can save both time and money in the long run. Understanding which elements are most prone to failure allows operators to anticipate repairs and avoid costly downtime.

Frequent Mechanical Failures

One of the most common issues in agricultural machines is a malfunctioning engine system. Overheating, poor fuel efficiency, or irregular starting are often signs that certain engine components, like filters or pumps, need replacing. Another frequent problem area is the transmission, where worn-out gears or fluid leaks can hinder smooth operation. Regular checks of these areas can prevent more serious breakdowns and ensure consistent performance.

Identifying and Replacing Worn Parts

When a component fails, it’s essential to identify the exact replacement needed. Components such as belts, seals, and hydraulic hoses are often the first to show signs of wear and require timely replacement. Using an accurate reference guide helps you find the correct part number and specifications. Ensuring that you are using the right replacements is critical for maintaining the machine’s efficiency and safety.