When it comes to maintaining and repairing a tractor, having a clear understanding of its key components is essential. Knowing the layout and function of each element allows for smoother troubleshooting and quicker fixes, ensuring optimal performance for years to come.

Whether you’re a seasoned mechanic or a tractor owner looking to make simple repairs, having access to detailed visuals and a thorough breakdown of the machinery helps you navigate through the repair process with ease. Identifying each section accurately is crucial to avoid unnecessary damage and costly errors.

In this guide, you’ll gain insights into the essential components, how they work together, and tips for proper maintenance. By the end, you’ll have the confidence to tackle common issues and extend the lifespan of your machine. Effective care and attention are key to keeping your equipment running smoothly and efficiently.

Massey Ferguson 35 Tractor Overview

The tractor is a vital piece of equipment for agricultural work, offering durability and versatility across various tasks. Designed to handle both light and heavy-duty jobs, it has become an essential tool for farmers and landowners alike.

Its robust engine and solid frame ensure reliability in tough conditions, making it suitable for a wide range of operations, from tilling fields to hauling materials. Power and efficiency are central to its design, making it an ideal choice for those seeking reliable performance on the field.

This model has been praised for its user-friendly features and easy maintenance. Understanding the mechanics and layout of the tractor allows owners to keep it in top working condition for years, minimizing downtime and increasing productivity.

Essential Components for Tractor Maintenance

Proper maintenance of a tractor relies on understanding the core elements that keep it running smoothly. Regular inspection and care of these critical components help prevent costly repairs and extend the lifespan of the machine.

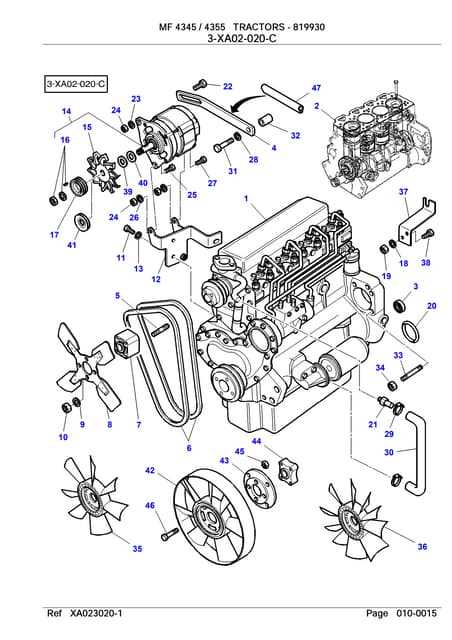

- Engine: The heart of the tractor, ensuring power and performance for various tasks. Regular oil changes and air filter replacements are key to keeping it efficient.

- Transmission: This system transfers power from the engine to the wheels. Checking fluid levels and inspecting for leaks ensures it runs smoothly.

- Hydraulic System: A vital part of lifting and moving heavy loads. Keeping the hydraulic fluid at the correct level and replacing worn seals is necessary for proper operation.

- Cooling System: Prevents overheating by circulating coolant. Regularly checking the radiator and coolant levels helps maintain engine temperature during use.

- Battery: Provides the power to start the engine and run electrical components. Regular cleaning and checking for corrosion help avoid starting issues.

By focusing on these essential systems, you can ensure your tractor remains in optimal condition, ready to tackle any task. Proper care of these parts not only improves efficiency but also reduces the risk of unexpected breakdowns.

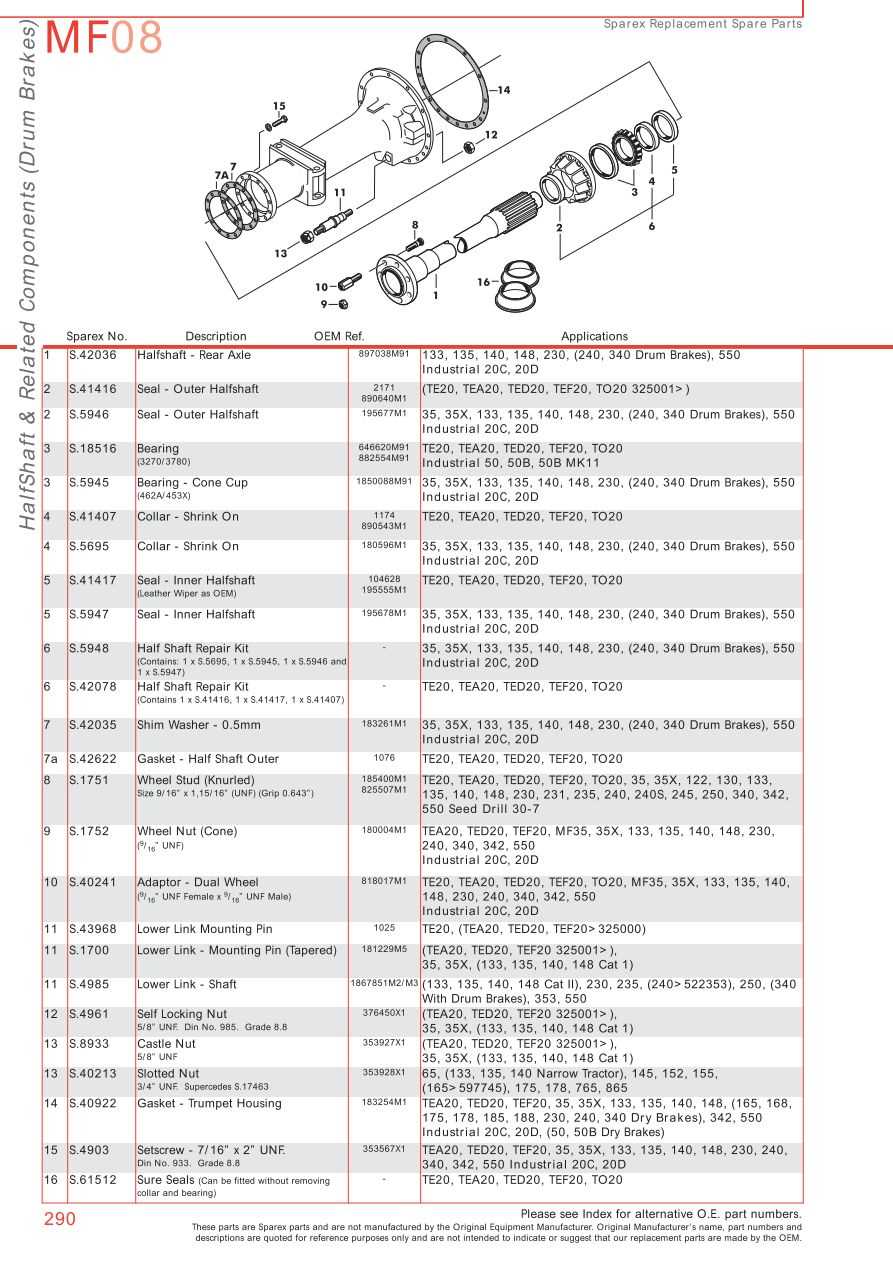

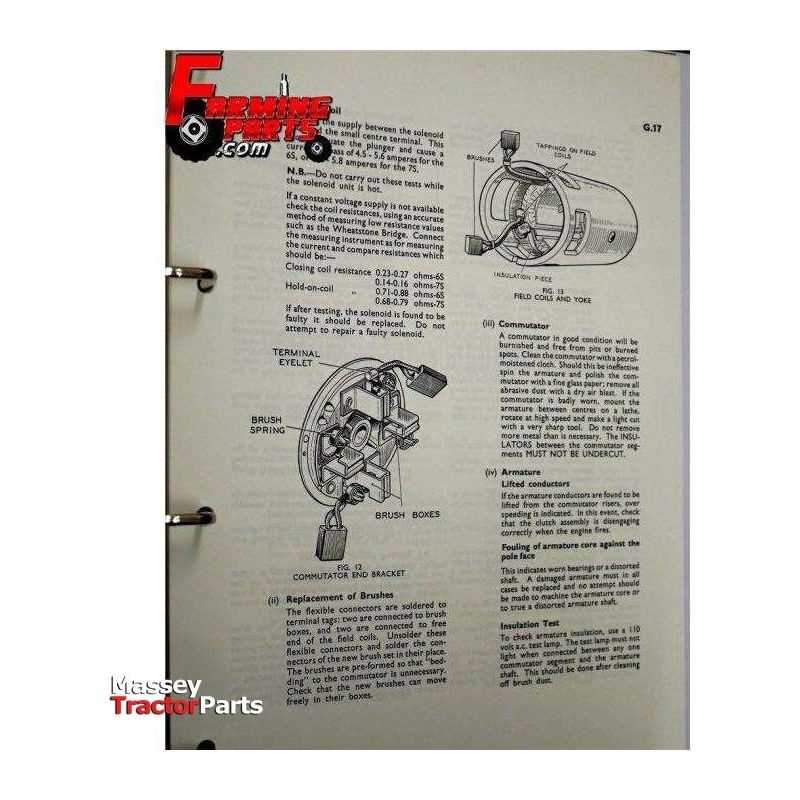

Step-by-Step Repair with Parts Diagram

Repairing a machine requires a structured approach, especially when working with complex systems. By breaking down the process into clear steps, you can identify issues and resolve them efficiently. Having a visual guide of key components helps simplify this task, allowing you to focus on each element individually.

Start by assessing the problem thoroughly. Isolate the malfunctioning area and gather the necessary tools. Using an illustration of the machine’s components, locate the damaged part and identify any related issues. This will help you understand the proper steps for disassembly and repair.

After the faulty part is removed, check for any wear on connected components. Replace damaged sections as needed and ensure that all connections are secure before reassembling the equipment. Once reassembled, test the machine to confirm that it is operating correctly.

Following this step-by-step approach ensures that repairs are completed methodically, reducing the likelihood of errors and enhancing the longevity of the equipment.