Understanding the inner workings of a spray tool can significantly enhance your performance, whether you’re an experienced artist or a beginner. A well-maintained setup ensures smoother operation and longer lifespan, making it a critical aspect of your craft. This guide will help you grasp the various components that come together to form a highly functional tool for precision work.

Each component plays a crucial role in the overall functionality, and recognizing how they interact can improve your ability to troubleshoot, clean, and optimize the device. By getting familiar with each piece, you can easily identify common issues and handle maintenance tasks with confidence.

With the right knowledge, you’ll be able to fully understand how every part contributes to the tool’s performance and how to best care for them to achieve optimal results. This will not only improve your technique but also extend the life of your equipment.

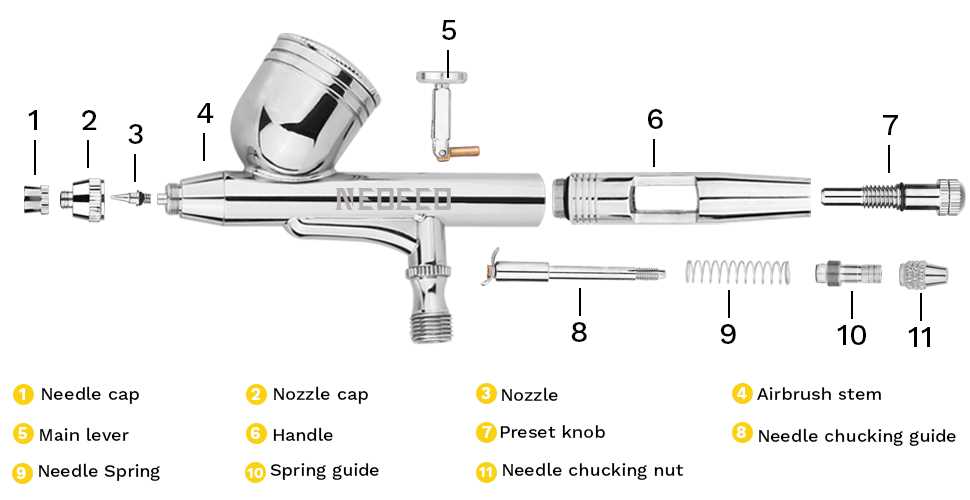

Understanding the Master Airbrush Components

To fully appreciate how a spray tool operates, it’s important to break down its individual elements. Each component, from the trigger to the nozzle, works in harmony to create precise lines and smooth finishes. Familiarity with these pieces allows for better care and troubleshooting, ensuring your tool performs at its best every time.

Key Functional Elements

At the heart of the setup is the trigger mechanism, which controls the airflow and paint delivery. This vital part allows for variable control, adjusting the intensity and flow of the medium. The nozzle and needle work together to regulate the spray pattern, ensuring consistent and even coverage. Understanding how these elements interact is essential for mastering the tool.

Maintenance and Care

Regular cleaning and upkeep are crucial for maintaining smooth operation. Parts such as the needle and nozzle should be carefully cleaned after each use to prevent clogs and maintain precision. Proper storage and handling of these delicate components also ensure longevity, preventing unnecessary wear and tear over time.

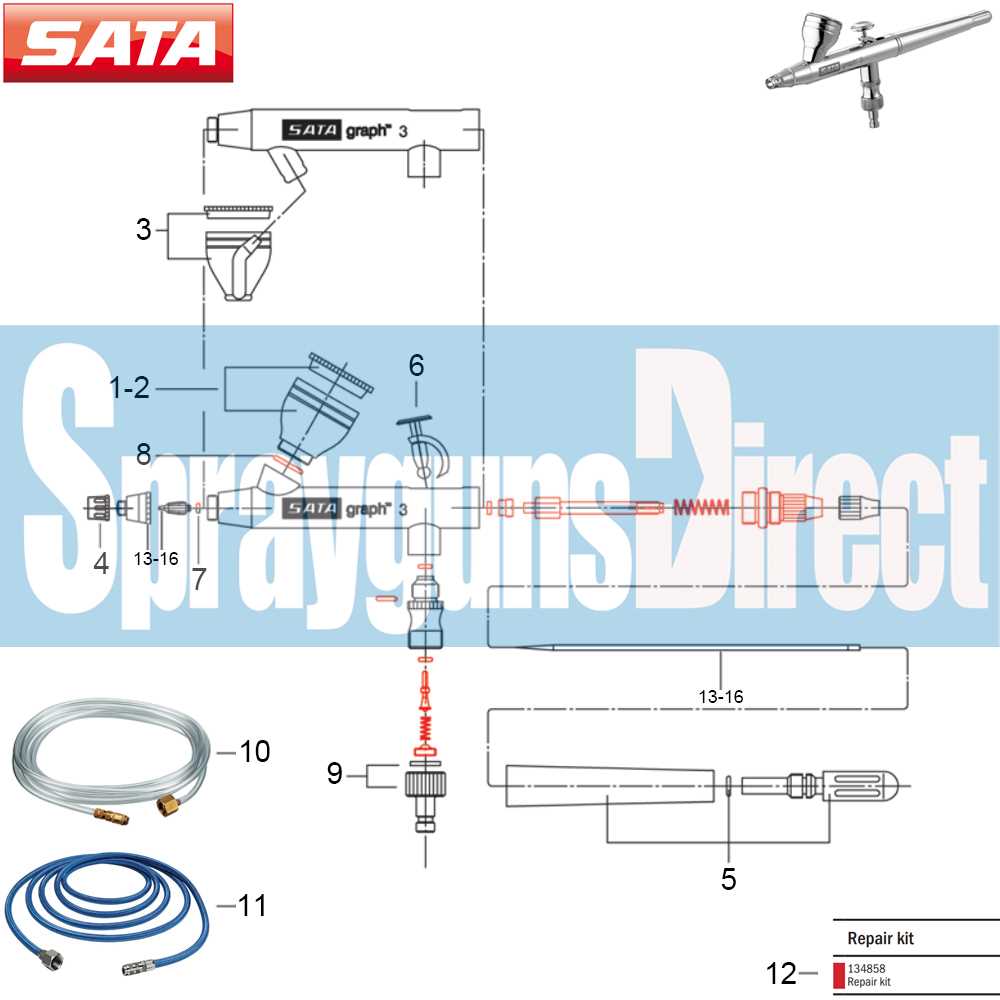

Key Elements of Master Airbrush System

In order to achieve precision and control, it is essential to understand the core components that make up a spray system. Each element plays a unique role in delivering the right flow and consistency, ensuring the tool functions effectively. Familiarity with these parts not only enhances performance but also makes maintenance and troubleshooting much simpler.

The Trigger and Control Mechanism

The trigger serves as the primary control for adjusting both the airflow and the flow of the medium. Its functionality directly impacts the tool’s ability to create fine details or broad coverage. Proper handling of the trigger mechanism is crucial for achieving consistent results during use.

Nozzle and Needle Assembly

The nozzle and needle are key in regulating the size and shape of the spray pattern. These parts ensure that the medium is delivered precisely where it’s needed, allowing for controlled and even application. Regular inspection and cleaning of these components are essential to avoid clogging and maintain a smooth, reliable performance.

How to Maintain Master Airbrush Parts

Regular care and maintenance are essential to keep your spray tool working efficiently and extend its lifespan. Proper cleaning and storage prevent build-up and damage, ensuring that each component continues to perform at its best. By following simple maintenance steps, you can avoid costly repairs and enjoy consistent results with every use.

Start by cleaning the nozzle and needle after each session to prevent clogging. A thorough rinse with water or cleaning solution is necessary to remove any leftover paint. Additionally, disassemble the tool periodically to inspect for wear or buildup that may affect performance. Keeping the trigger mechanism free of debris and lubricated will also help maintain smooth operation and prevent malfunctions.