When working with complex machines, having a clear overview of the individual components is essential for efficient troubleshooting and maintenance. A detailed layout of each part allows users to identify and understand the role of each element within the system. This knowledge is crucial for ensuring smooth operation and extending the lifespan of the equipment.

By examining the system’s structure, users can gain valuable insights into the relationships between different parts, making it easier to diagnose issues and perform repairs. Proper understanding also ensures that any replacements or upgrades are done with precision, avoiding potential errors during reassembly.

In this section, we explore how to interpret the assembly layout and the importance of knowing every individual component. Whether you’re a technician or a beginner, having access to a comprehensive system map will simplify your tasks and enhance your overall experience with the machinery.

Understanding the Mechanical System Components

Every machine relies on a variety of interconnected elements that work together to perform its functions. Understanding the individual components and how they contribute to the overall system can significantly improve your ability to troubleshoot and maintain the equipment. In this section, we will break down the core elements that make up the machine’s structure, providing clarity on their roles and interrelationships.

Key Functional Units

The machine consists of several functional units that each play a vital role in ensuring smooth operation. Each unit is designed to handle specific tasks, from powering up the system to regulating performance. Recognizing the function of these key units allows for better diagnosis when something goes wrong and helps ensure that repairs or replacements are handled correctly.

Interaction Between Components

One of the most important aspects of understanding the system is grasping how the components interact. The components are designed to work in harmony, each depending on others to perform specific actions. A deep understanding of these relationships will enable users to pinpoint issues more accurately and take corrective actions swiftly. By mapping out these connections, you can make informed decisions about maintenance and troubleshooting.

Key Elements in the System Layout

To fully comprehend a machine’s structure, it’s essential to focus on the critical elements that define its operation. These core components are often represented in a visual guide that highlights their interconnection and function. Understanding these elements provides insight into the overall workflow and ensures accurate identification during maintenance or repairs.

Each key element in the system plays a specific role in achieving the desired performance. From the primary control units to the smaller supporting parts, knowing how these pieces fit together allows for more efficient diagnostics and decision-making when issues arise. It’s important to familiarize yourself with these key elements to ensure proper handling and longevity of the system.

How to Read the System Layout

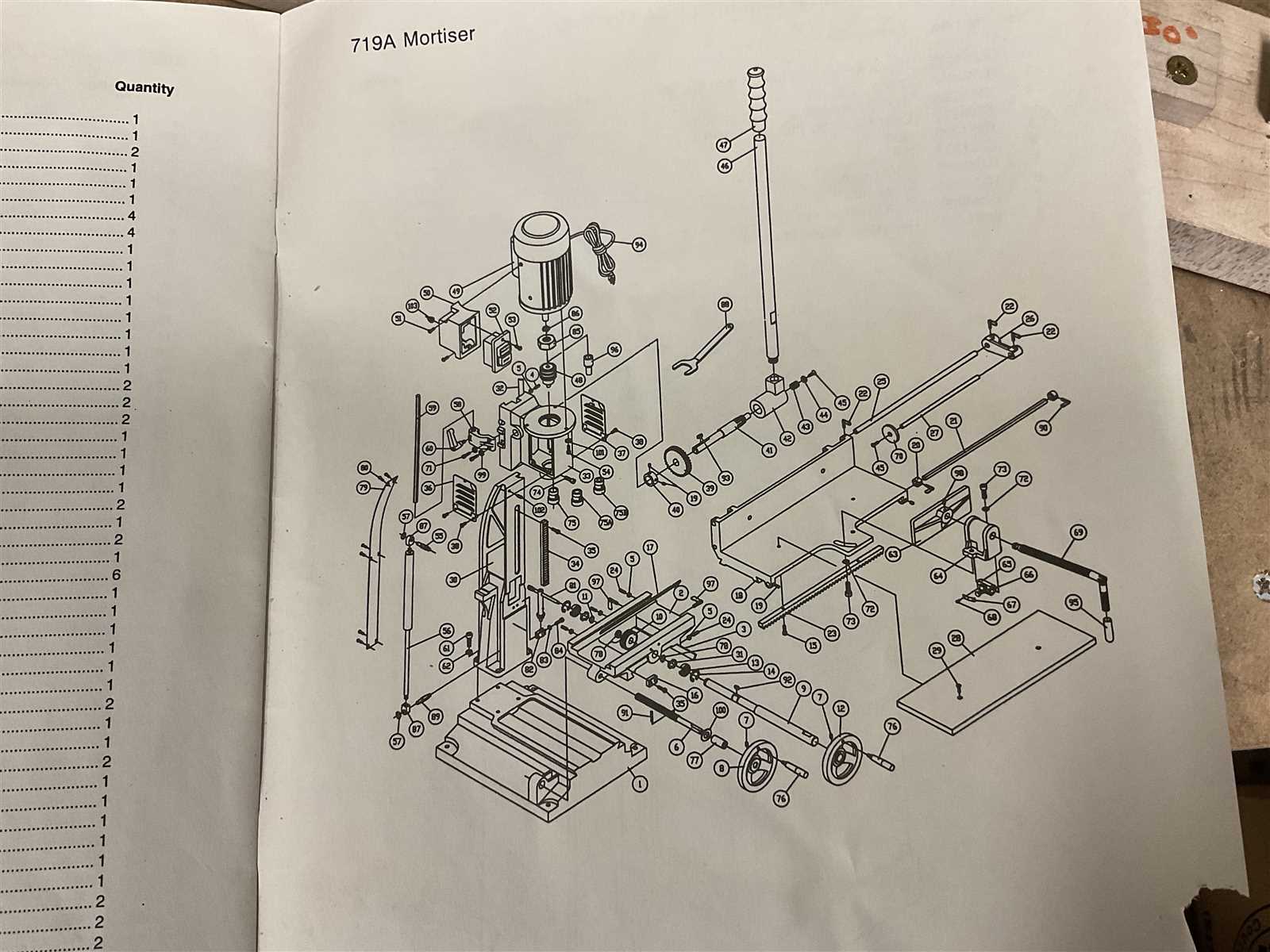

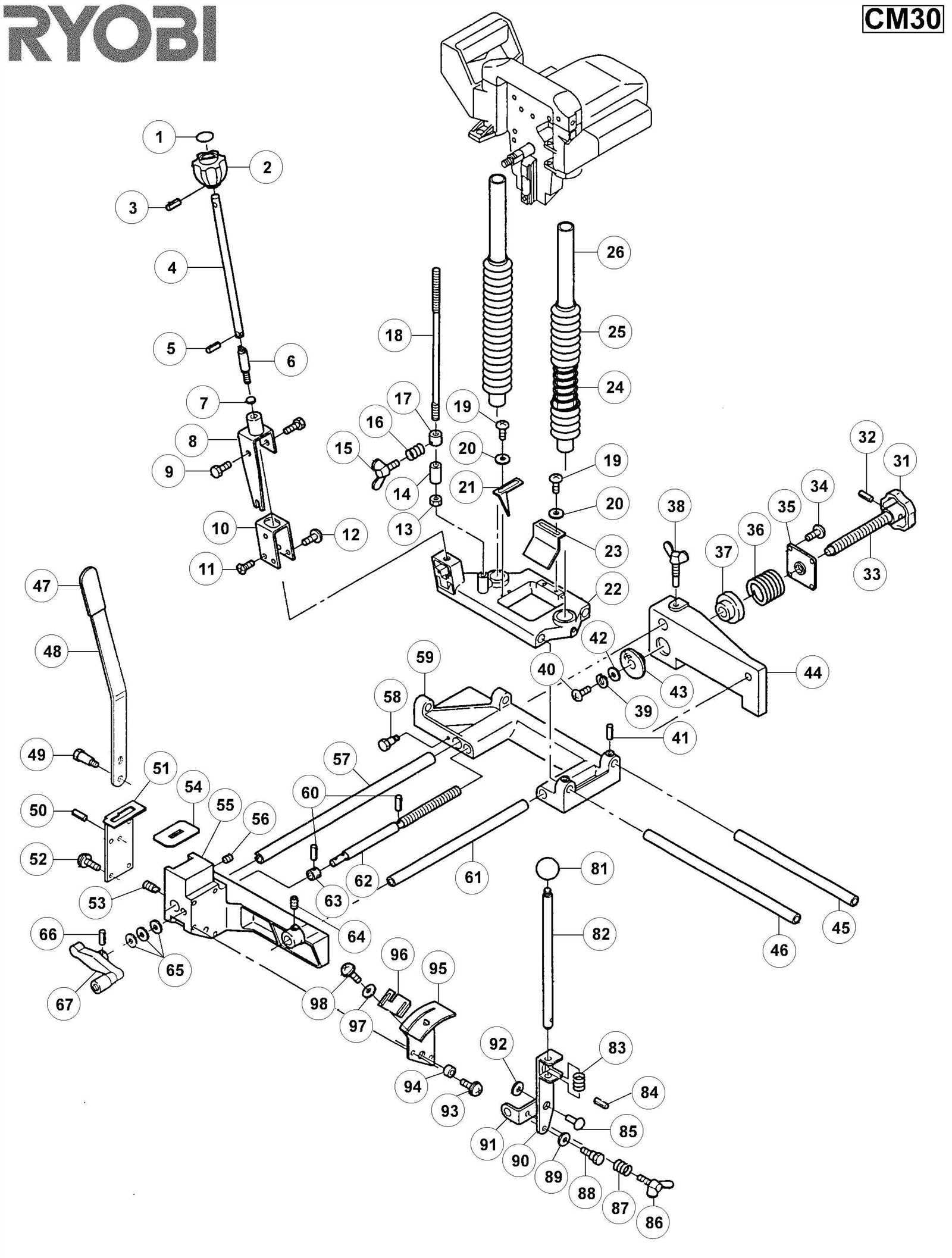

Understanding how to interpret a system layout is crucial for anyone working with complex machinery. This guide allows users to decode the representation of the machine’s components, helping them quickly identify individual parts and their connections. Knowing how to read this information simplifies the process of troubleshooting and performing maintenance tasks.

The layout often includes various symbols and notations that correspond to different units within the machine. Each symbol provides information on the type of component and its function within the system. By familiarizing yourself with these visual cues, you can efficiently locate the parts you need to work with and understand their relationship to one another.

Step-by-Step Guide for Beginners

For those new to working with complex machinery, understanding how to navigate through system layouts can seem challenging. This guide will break down the process into simple steps, helping you gain confidence in interpreting technical schematics and identifying critical components. With a clear step-by-step approach, you’ll be able to approach repairs or maintenance with ease.

Familiarize Yourself with Symbols

Each layout includes a set of symbols that represent different units within the system. Start by identifying these symbols and understanding what they stand for. Once you recognize the basic icons, you’ll be able to follow the layout more efficiently and pinpoint the components that require attention.

Follow the Connections

After identifying the components, the next step is to understand how they are connected. Pay attention to the lines and arrows that link different units. These connections show the relationships between various parts, helping you understand the flow of operation within the system.

Importance of Accurate Component Identification

Identifying each component correctly is crucial for maintaining the efficiency and functionality of any system. Accurate recognition of individual elements ensures that any maintenance or troubleshooting is done with precision, preventing errors and costly repairs. Inaccurate identification can lead to confusion, inefficiency, and even system damage.

Here are some reasons why precise identification is important:

- Improved Diagnostics: Knowing the exact components involved helps in identifying problems quickly, making repairs faster and more accurate.

- Effective Replacements: Correctly identifying faulty parts ensures that only the necessary elements are replaced, avoiding unnecessary expenses.

- Proper Functionality: Ensuring each part is recognized and handled properly helps maintain the system’s optimal performance over time.

- Safety: Incorrect identification can result in improper handling of components, leading to potential safety risks for the user and system.

By accurately identifying every element, you contribute to the longevity and reliability of the system, ensuring that each operation is performed smoothly and without complications.