When maintaining or repairing gardening machinery, it’s essential to understand the key components that keep the equipment running smoothly. A clear visual representation of these elements can make identifying issues and performing necessary fixes much easier. By gaining insight into how each part functions, you can improve the efficiency and longevity of the machine.

Familiarizing yourself with the equipment’s structure allows you to quickly locate areas needing attention, whether it’s for routine maintenance or troubleshooting unexpected problems. With proper knowledge, you’ll be able to make informed decisions when it comes to repairs or upgrades, avoiding common pitfalls.

In this guide, we will explore the essential components of your gardening machinery, how they interact with one another, and practical tips for ensuring everything is in optimal working condition. Understanding these connections is a critical step towards effective operation and long-term durability.

Understanding the Components of a Garden Cultivator

The proper functioning of any garden cultivator relies on the seamless interaction of its various elements. These components work together to ensure smooth operation, making it easier to maintain soil quality and prepare land for planting. Recognizing how each part contributes to the overall performance is crucial for troubleshooting and performing maintenance tasks efficiently.

Key Functional Elements

The engine acts as the powerhouse, supplying the necessary energy for operation. Its connection to other parts, such as the drive system, enables the machine to move and perform various tasks. Additionally, the rotating blades or digging implements are vital for soil aeration, helping to break up compacted earth and incorporate nutrients.

Critical Maintenance Areas

Regular upkeep focuses on essential sections like the fuel system and gear mechanism. These areas, if not properly maintained, can lead to poor performance or malfunction. Proper lubrication of moving parts ensures longevity and optimal functioning, reducing wear and tear over time.

Key Parts and Their Functions Explained

Understanding the core components of a garden cultivator is essential for ensuring smooth operation and maintaining optimal performance. Each element serves a specific role, contributing to the overall effectiveness of the machine. By knowing the function of each part, you can identify potential issues and take appropriate action to keep the equipment running efficiently.

- Engine: The engine is the heart of the machine, converting fuel into mechanical energy to power the entire system. It drives the motion of all the moving parts, from the wheels to the working elements.

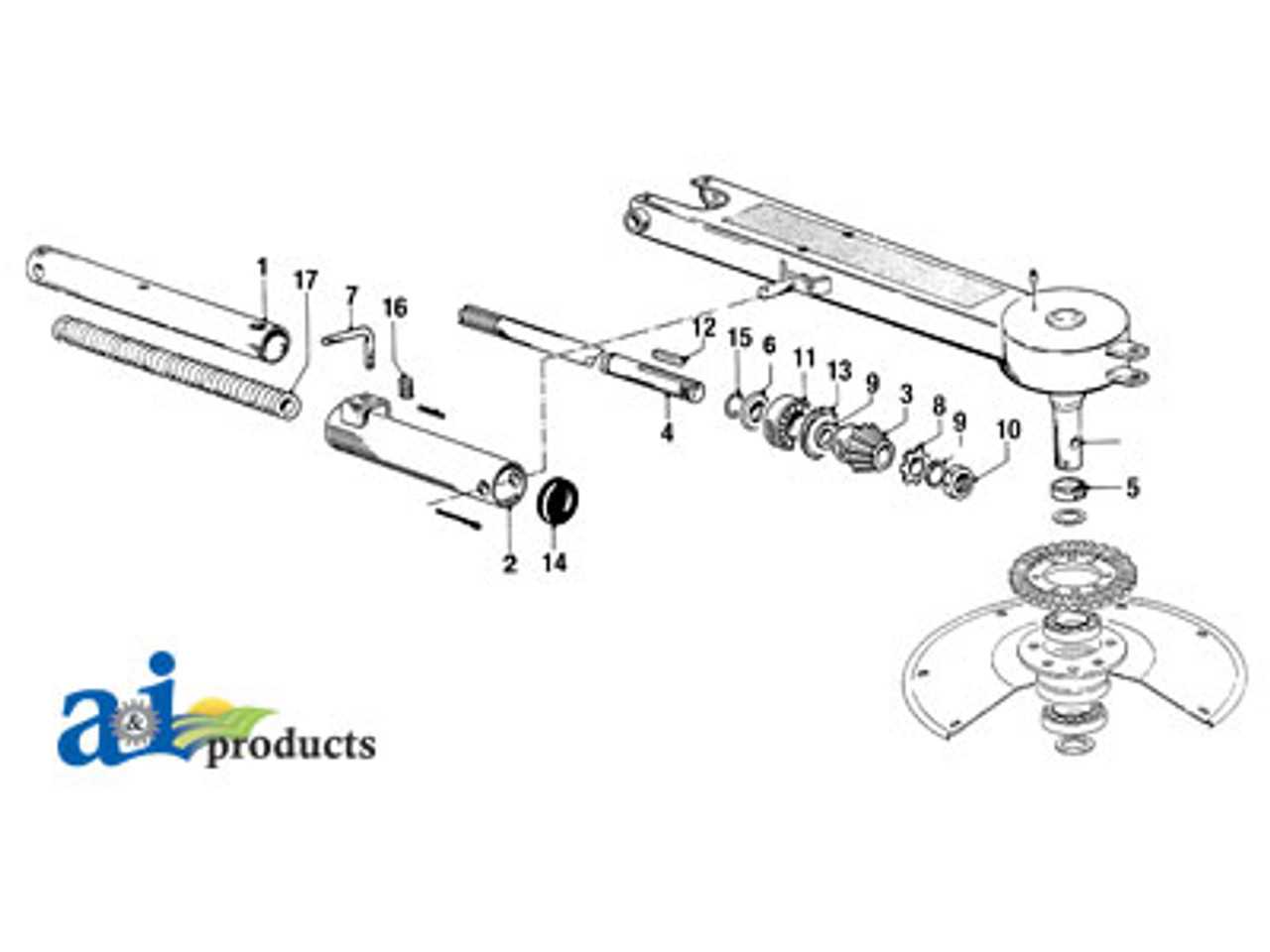

- Drive Mechanism: This system connects the engine to the wheels, enabling movement across the ground. It includes gears, belts, and pulleys, which help control the speed and direction of the machine.

- Rotating Blades or Tines: The rotating blades or tines are responsible for cutting into the soil. They dig, break up compacted earth, and allow air and water to reach the roots of plants, promoting healthy growth.

- Fuel System: This includes the tank, filter, and lines that deliver fuel to the engine. A clean and efficient fuel system ensures reliable engine performance and reduces the risk of malfunctions.

- Control Levers: The control levers allow the operator to adjust the speed, direction, and depth of the cultivating implements. They provide the flexibility needed to perform various tasks with precision.

Each of these elements is interconnected, with the performance of one part affecting the operation of the entire system. Proper maintenance of each key component ensures that the cultivator remains in good working condition and can handle a variety of tasks in the garden.

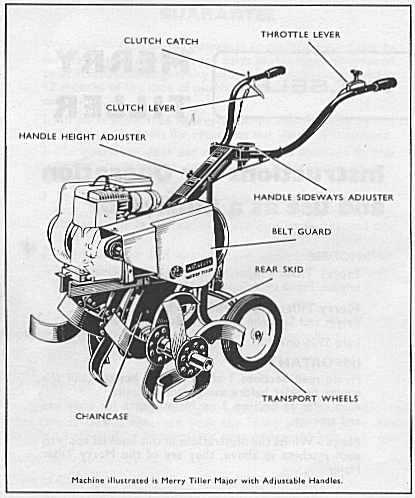

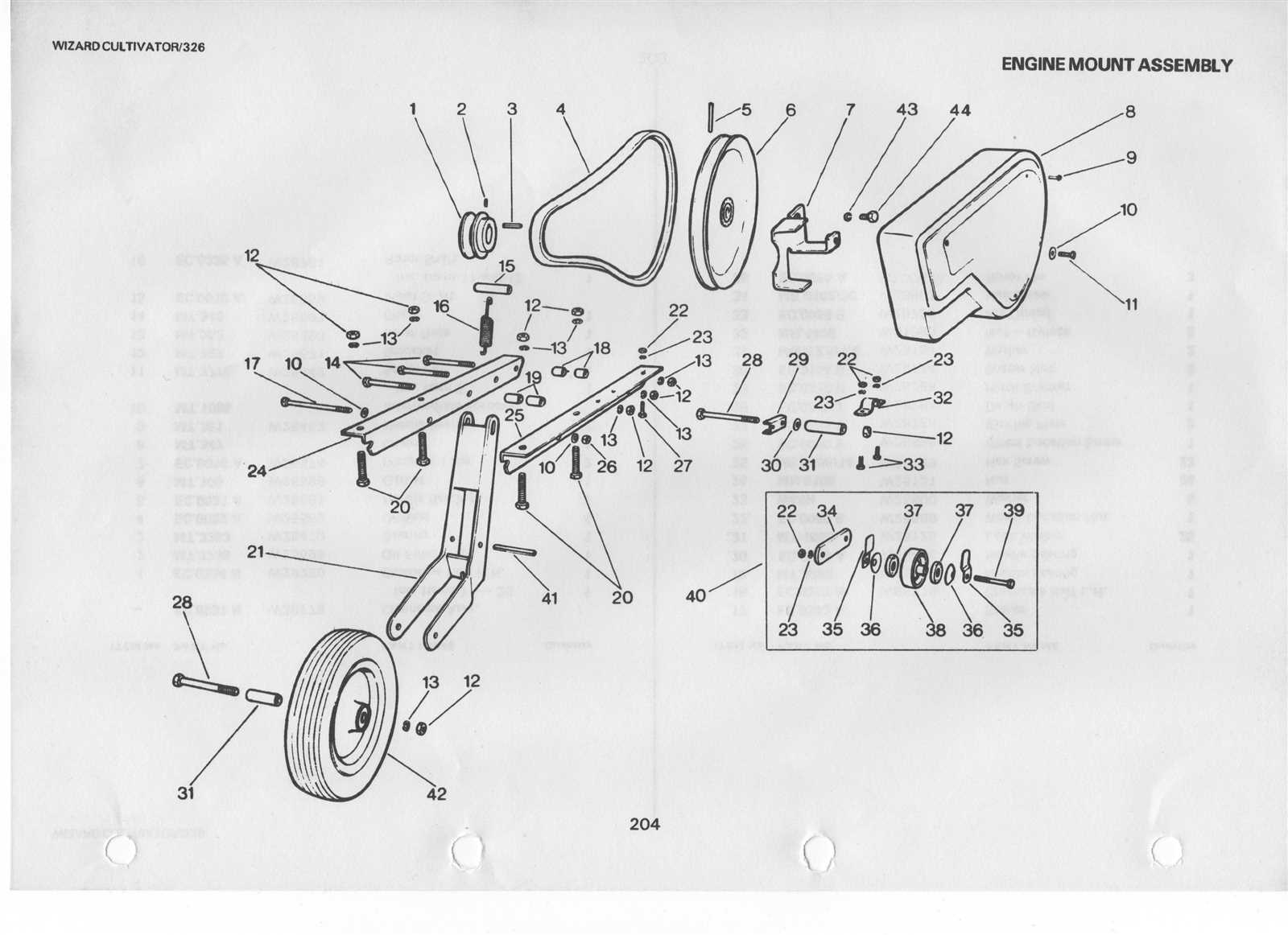

How to Identify Tiller Parts Easily

Recognizing the individual components of garden machinery can sometimes be challenging, especially when dealing with complex systems. However, by understanding the basic structure and design of the equipment, you can quickly locate and identify the essential elements that make up the machine. Knowing where each component fits and how it interacts with the others is key to performing repairs and maintenance efficiently.

Using Visual Cues and Labels

Many machines have labels or part numbers stamped on their components, which can be useful for identification. Paying attention to these markings can help you easily trace the part’s function and locate the correct replacement if needed. Additionally, most garden machines feature visual cues, such as specific shapes or sizes, that help differentiate one part from another.

Reference Tables and Guides

Using a reference guide or table that lists the names and functions of each part can simplify the identification process. Below is an example table of common machine components and their respective functions:

| Component | Description |

|---|---|

| Engine | The primary power source that drives the machine. |

| Rotating Blades | Cut and break up soil for aeration. |

| Drive System | Transfers power from the engine to the wheels for movement. |

| Fuel Tank | Holds and supplies fuel to the engine. |

| Control Levers | Allow the user to adjust settings like speed and depth. |

With the right tools and resources, identifying and understanding each component becomes much easier. Reference guides and visual aids will help ensure you can quickly pinpoint the parts that need attention.

Visual Guides for Quick Reference

When it comes to maintaining or repairing garden machinery, having clear and easily accessible visual guides can make a significant difference. These references provide an instant overview of the key components, helping you identify what needs attention at a glance. With the right visual resources, troubleshooting becomes simpler and faster, reducing the time spent on identifying and fixing issues.

Visual aids such as labeled images, exploded views, and reference charts allow for quick identification of each part and its location within the system. Whether you are looking for specific components or trying to understand how they work together, these guides can be invaluable in saving time and ensuring the job is done correctly.

For example, an exploded view of a garden machine can break down each part’s function and show how they interact. Similarly, a labeled diagram with color-coded components can help you pinpoint the exact area that requires attention, simplifying the repair or maintenance process.

Maintaining Your Tiller Parts Effectively

Proper maintenance is crucial for ensuring the longevity and optimal performance of garden machinery. Regular care and attention to the key components will help prevent breakdowns and costly repairs, while also improving efficiency. By understanding the specific needs of each element, you can establish a routine that keeps the equipment in top condition throughout its lifespan.

One of the most important aspects of maintenance is keeping all moving parts well-lubricated and free of debris. Over time, components can wear down due to friction or build-up of dirt, which can negatively impact their function. Regularly cleaning the system and checking for any signs of wear can prevent more serious issues from arising.

Another key maintenance task involves inspecting the fuel system and engine components. Keeping the fuel tank clean and using fresh fuel can prevent clogging and improve the engine’s performance. Additionally, replacing air filters and spark plugs as needed ensures that the engine runs efficiently and starts without problems.

Lastly, always follow the manufacturer’s guidelines for maintenance intervals and recommended parts replacement. This will help you stay on top of necessary repairs and keep your machinery performing as it should, even after years of use.