For anyone maintaining or restoring the MF 35 tractor, understanding its structure and internal layout is essential. The machine’s design includes a variety of interconnected elements, each contributing to its overall performance. Having a clear view of these components aids in efficient repairs and upkeep.

By analyzing the various sections of the tractor, you can identify the purpose and function of each individual unit. This knowledge is crucial for anyone working on the vehicle, as it helps diagnose issues, prevent breakdowns, and ensure that all systems operate smoothly.

In this guide, we’ll delve into the key components of the MF 35, offering insights into how each part interacts with others. Knowing these connections will empower you to make informed decisions when performing maintenance or fixing faults.

Understanding the MF 35 Components

The MF 35 is a complex piece of machinery, consisting of multiple interconnected systems that work together to ensure smooth operation. Each section plays a vital role in the tractor’s overall performance, and understanding these systems is crucial for anyone involved in its maintenance or repair.

From the engine to the hydraulic system, every element has a specific function that contributes to the vehicle’s capabilities. Recognizing the importance of each unit helps in diagnosing issues and performing targeted repairs, ensuring the machine continues to operate at peak efficiency.

By familiarizing yourself with the internal structure and how each component interacts with others, you can better maintain the tractor and prevent costly repairs. Knowledge of these systems allows for informed decision-making during troubleshooting and ensures that all functions are properly aligned for optimal performance.

Key Parts and Their Functions

Understanding the primary components of the MF 35 and their roles is crucial for efficient operation and maintenance. Each unit within the machine serves a specific function, ensuring the overall performance and longevity of the tractor. By breaking down the key elements, we can gain a better understanding of how the tractor operates as a whole.

Engine and Power Transmission

The engine is the heart of the MF 35, providing the necessary power for all operations. It is connected to the transmission system, which converts the engine’s energy into mechanical power that drives the wheels. This system includes gears, shafts, and other elements that help transmit power to the wheels, allowing for movement and other essential functions.

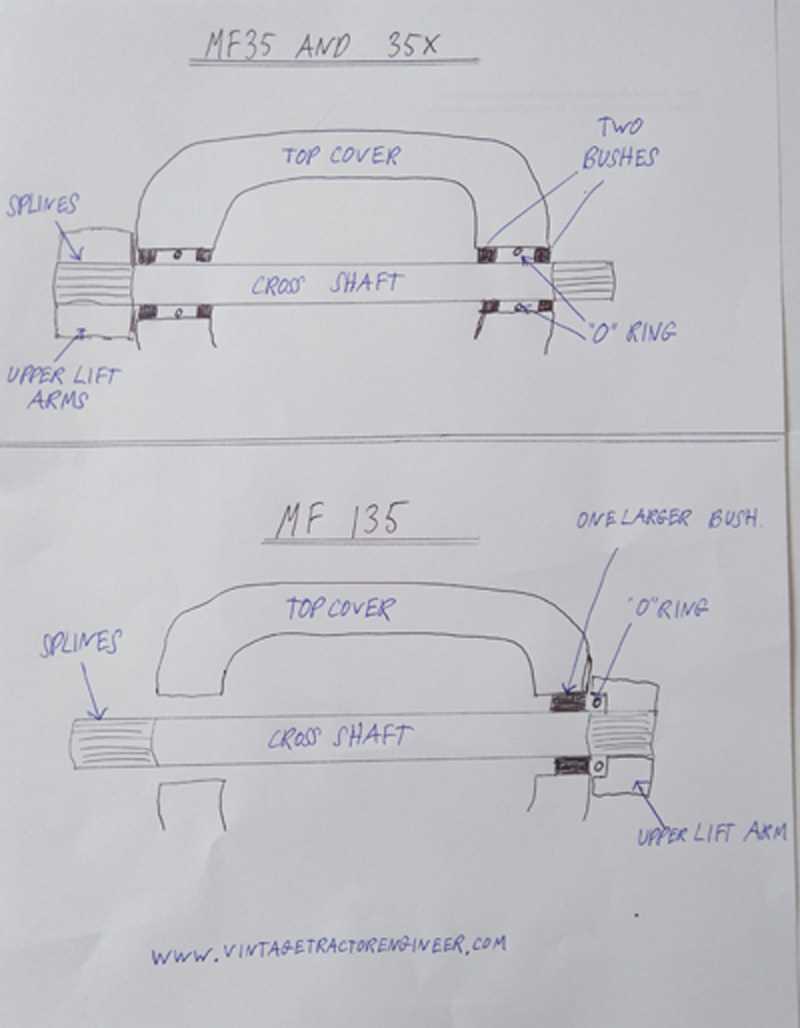

Hydraulic System

The hydraulic system is another crucial part of the MF 35, responsible for powering attachments and lifting equipment. This system uses fluid pressure to operate various mechanisms, such as the lifting arms and other implements. By controlling the flow of hydraulic fluid, operators can adjust the force and movement of these attachments, ensuring they perform their tasks efficiently.

Step-by-Step MF 35 Maintenance

Proper upkeep of the MF 35 is essential for maintaining its functionality and extending its lifespan. A thorough maintenance routine involves regular checks and servicing of different systems to ensure everything operates smoothly. By following a systematic approach, potential issues can be identified early, preventing major breakdowns and costly repairs.

Step 1: Begin by inspecting the engine. Regular oil changes and air filter replacements are vital for keeping the engine running efficiently. Check the coolant levels and make sure there are no leaks in the system that could lead to overheating.

Step 2: Examine the transmission and differential components. Ensure that the fluid levels are adequate and that the system operates without unusual sounds or resistance. If there are any signs of wear, these should be addressed promptly to avoid further damage.

Step 3: Focus on the hydraulic system. Regularly check for leaks and monitor the hydraulic fluid level. If the system shows signs of decreased performance, it may require flushing or a fluid change to maintain optimal function.

Step 4: Inspect the braking system. Ensure that the brake pads and components are in good condition and functioning properly. Worn-out parts should be replaced to ensure the safety and effectiveness of the system.

By following this step-by-step guide, the MF 35 can be kept in top condition, minimizing the risk of failure and maximizing its performance over time.

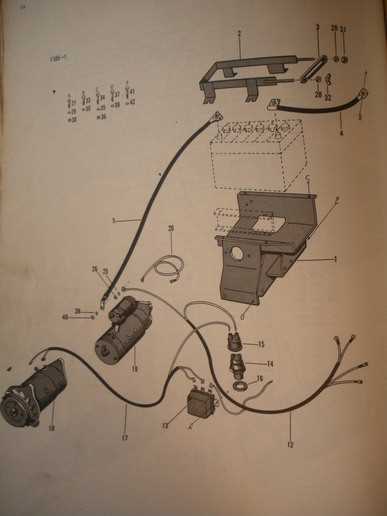

How to Use the Parts Diagram

Understanding how to navigate the visual representation of the MF 35’s components is essential for accurate maintenance and repairs. These visual guides help you identify individual units, their connections, and their functions within the system. By using these resources effectively, you can easily locate any issues and determine the necessary actions for repair or replacement.

To get the most out of these guides, follow these steps:

- Start with the overview: Examine the complete layout to familiarize yourself with the general organization of the machine.

- Identify key components: Focus on the major systems such as the engine, transmission, and hydraulic units to understand their interconnections.

- Follow the flow: Trace the connections and interactions between units to get a better understanding of how each part works with others.

- Spot potential issues: Look for any irregularities or components that appear worn, cracked, or damaged. This can help in early identification of potential failures.

- Use the references: Refer to part numbers and labels for more detailed information on specific units and their specifications.

By following this approach, you’ll be able to quickly diagnose problems and plan your repairs with precision, making the process smoother and more efficient.

Troubleshooting Common MF 35 Issues

Despite the MF 35’s durable construction, various issues can arise during regular operation. Identifying and addressing these problems promptly is essential for maintaining the tractor’s efficiency and preventing further damage. This section will help you recognize some common challenges and offer effective solutions to resolve them.

Engine Not Starting: If the engine fails to start, check the fuel system for blockages or leaks. Ensure that the battery is fully charged and the connections are secure. Inspect the ignition system for faults and verify that the starter motor is functioning properly.

Overheating: Overheating can be caused by low coolant levels, a clogged radiator, or a malfunctioning thermostat. Regularly check the cooling system to ensure there are no leaks and that it’s filled with the appropriate coolant. If overheating persists, inspect the radiator for blockages.

Hydraulic System Failure: A common issue with the MF 35 is a loss of hydraulic power. If attachments aren’t working properly, check the hydraulic fluid levels and ensure there are no leaks in the system. If the fluid is low, refill it and inspect the pump and hoses for wear or damage.

Transmission Problems: Difficulty shifting gears or grinding noises could indicate an issue with the transmission. Check the fluid levels and inspect for any visible damage. If the transmission is making unusual noises, it might require professional attention.

By addressing these common issues as soon as they appear, you can extend the life of your MF 35 and keep it running smoothly for years to come.