When working with complex equipment, having a clear view of the internal structure is essential for effective operation and maintenance. Knowing how different elements interact can significantly enhance the lifespan and functionality of the machine.

Breakdowns and repairs often require a detailed look at each section to ensure proper service. This overview helps operators and technicians identify specific areas that need attention, minimizing downtime and preventing larger issues.

By familiarizing oneself with the overall layout, it becomes easier to troubleshoot problems and perform routine upkeep. With this knowledge, anyone can gain confidence in managing repairs and maximizing the machine’s efficiency.

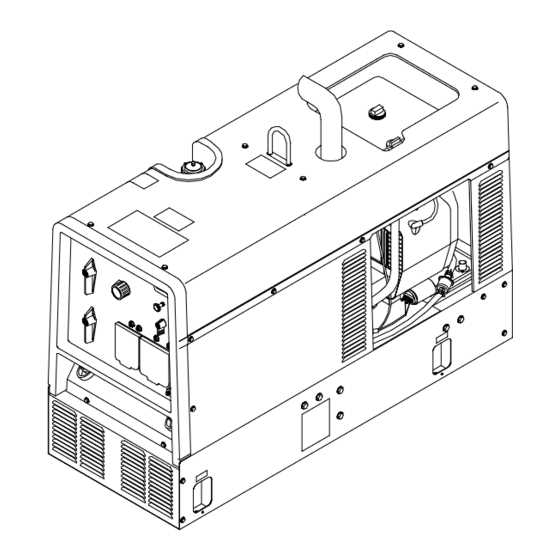

Miller Bobcat 225 Overview

This machinery represents a versatile and powerful solution for various industrial and construction tasks. Designed for efficiency and reliability, it stands out in its class for handling demanding jobs. Its robust engine and compact frame allow it to operate in tight spaces while maintaining excellent power output.

Key Features of the Equipment

The equipment is equipped with a range of advanced features that ensure smooth and consistent operation. From the hydraulic system to the operator controls, every component is engineered to optimize performance and ease of use. Its design allows for both precision and durability, making it a preferred choice for professionals.

Applications and Use Cases

This machine is widely used in construction, agriculture, and landscaping projects, among others. Its ability to adapt to different attachments and its ease of maneuverability make it ideal for a variety of tasks. Whether it’s lifting, digging, or moving materials, this equipment proves to be both reliable and efficient in a multitude of environments.

Essential Components of Bobcat 225

Every machine is built from a series of interdependent systems, each serving a specific function that contributes to its overall performance. Understanding these key systems is vital for operators and technicians, as it ensures efficient operation and simplifies maintenance tasks. The core components work together seamlessly to provide optimal power and control.

Hydraulic System

The hydraulic system plays a critical role in powering various functions of the machinery. It drives the lifting arms, controls the movement of attachments, and supports essential operations like digging and carrying materials. A well-maintained hydraulic system is crucial for smooth, responsive machine operation.

Drive Mechanism

At the heart of the equipment’s movement is its drive system, responsible for transferring power from the engine to the wheels or tracks. This mechanism ensures that the machine can move with precision and stability across different terrains, making it a versatile tool for numerous tasks. Proper upkeep of the drive system guarantees long-term durability and reliability.

Understanding the Parts Layout

Gaining a clear understanding of the internal layout of machinery is essential for proper operation and efficient maintenance. The arrangement of components affects not only the functionality but also the ease of access for repairs and routine servicing. By familiarizing oneself with the configuration, technicians can troubleshoot more effectively and ensure the equipment operates at peak performance.

Each section of the machine is designed to serve a specific function, and knowing how they connect allows for better management of resources and time during repairs. An organized layout helps operators recognize areas that require attention, ensuring long-term reliability and minimizing operational disruptions.