When maintaining or repairing your boat’s motor system, having a clear understanding of its individual components is essential. Knowing where each part fits and how it functions will help ensure that your motor runs efficiently and stays in good working order.

Accurate identification of the elements within the system is crucial for both troubleshooting and replacing worn-out or damaged parts. Whether you’re a seasoned enthusiast or new to the world of watercraft maintenance, understanding the layout and function of each component is key to successful repairs.

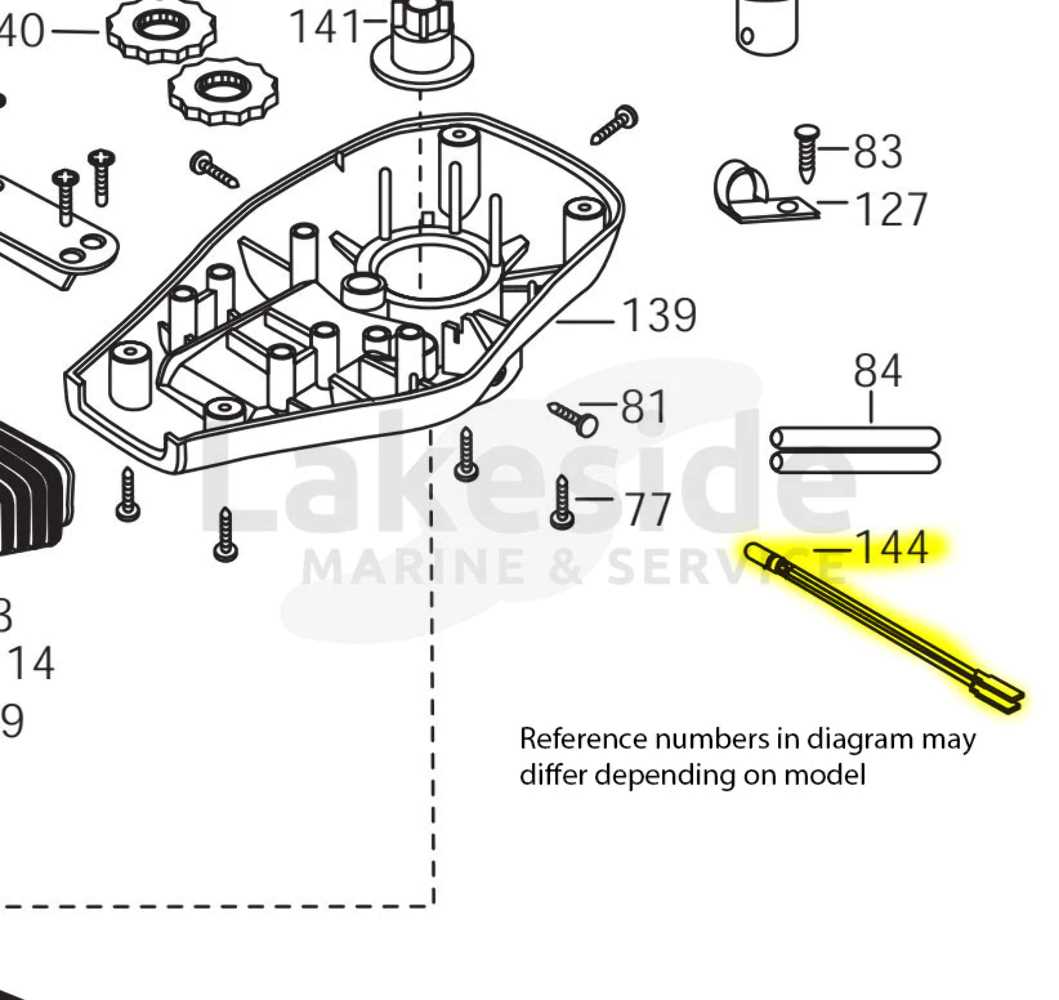

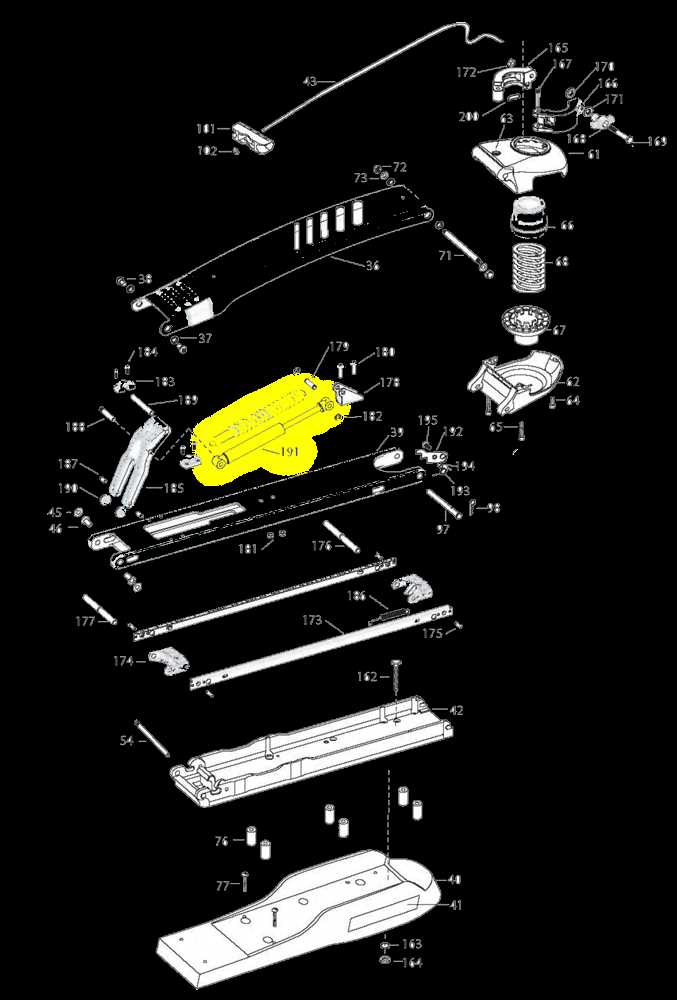

Detailed diagrams serve as invaluable tools for navigating the complexities of the motor’s internal structure. They allow you to pinpoint specific parts quickly, saving time and avoiding unnecessary confusion during the maintenance process.

Understanding Trolling Motor Components

Every trolling motor consists of various key elements that work together to provide optimal performance on the water. These individual components are designed to function seamlessly, ensuring smooth operation and durability even under challenging conditions. Understanding these elements is essential for anyone involved in the maintenance or repair of a motor system.

Each component plays a distinct role, from the propulsion system that drives the motor to the control mechanisms that allow you to adjust speed and direction. Recognizing the purpose of each part is crucial for diagnosing issues or performing upgrades. With a clear understanding, you can identify which parts require attention and avoid unnecessary replacements.

Familiarity with the motor’s structure also helps in ensuring proper assembly and disassembly during maintenance. Whether dealing with electrical systems, mechanical assemblies, or structural components, knowing how everything fits together will make the entire repair process more efficient and straightforward.

How to Use the Motor Component Layout

Understanding how to effectively utilize a component layout can greatly simplify the process of motor maintenance and repair. A well-organized layout provides a clear visual representation of each element, allowing you to identify and locate specific parts quickly. This tool is especially useful when troubleshooting issues or planning upgrades, as it eliminates confusion and saves valuable time.

To get the most out of the layout, start by familiarizing yourself with the overall structure. Focus on the key sections and understand the relationships between different parts. Once you have a general understanding, use the layout as a reference to pinpoint the exact location of any component that requires attention or replacement.

Whether you’re addressing a malfunction or performing routine maintenance, the layout will help you work with confidence. It offers a detailed view of each part’s function, allowing you to assess the motor’s condition and determine which elements need servicing without unnecessary guesswork.

Common Issues and Part Replacements

During the lifespan of a motor, various issues may arise that require attention. Identifying these problems early can prevent further damage and ensure the motor continues to operate efficiently. Often, these issues are related to worn-out or malfunctioning components, which may need to be replaced to restore optimal performance.

Electrical Problems and Fixes

One of the most common issues is electrical failure, often caused by worn wiring, faulty connections, or damaged switches. Inspecting the electrical system regularly is key to preventing such issues. If any part shows signs of wear, replacing it with a compatible component is essential for maintaining reliable functionality.

Mechanical Wear and Tear

Over time, mechanical parts such as propellers, shafts, and seals can wear out or become damaged. Regular maintenance can help identify these issues before they impact the motor’s performance. Replacing these components when they show signs of wear ensures smooth operation and extends the life of the motor.