For any boating enthusiast or professional, knowing the inner workings of their equipment is essential. When a motor is malfunctioning or requires maintenance, understanding its key elements can help you troubleshoot and ensure a longer lifespan. Having a clear view of the motor’s structure aids in identifying worn-out or damaged components that might need replacing.

Regular upkeep and timely repairs are crucial for maintaining optimal performance. By familiarizing yourself with the different parts of your equipment, you are in a better position to conduct effective maintenance. This knowledge empowers you to act quickly and decisively when problems arise, minimizing downtime and preventing further damage.

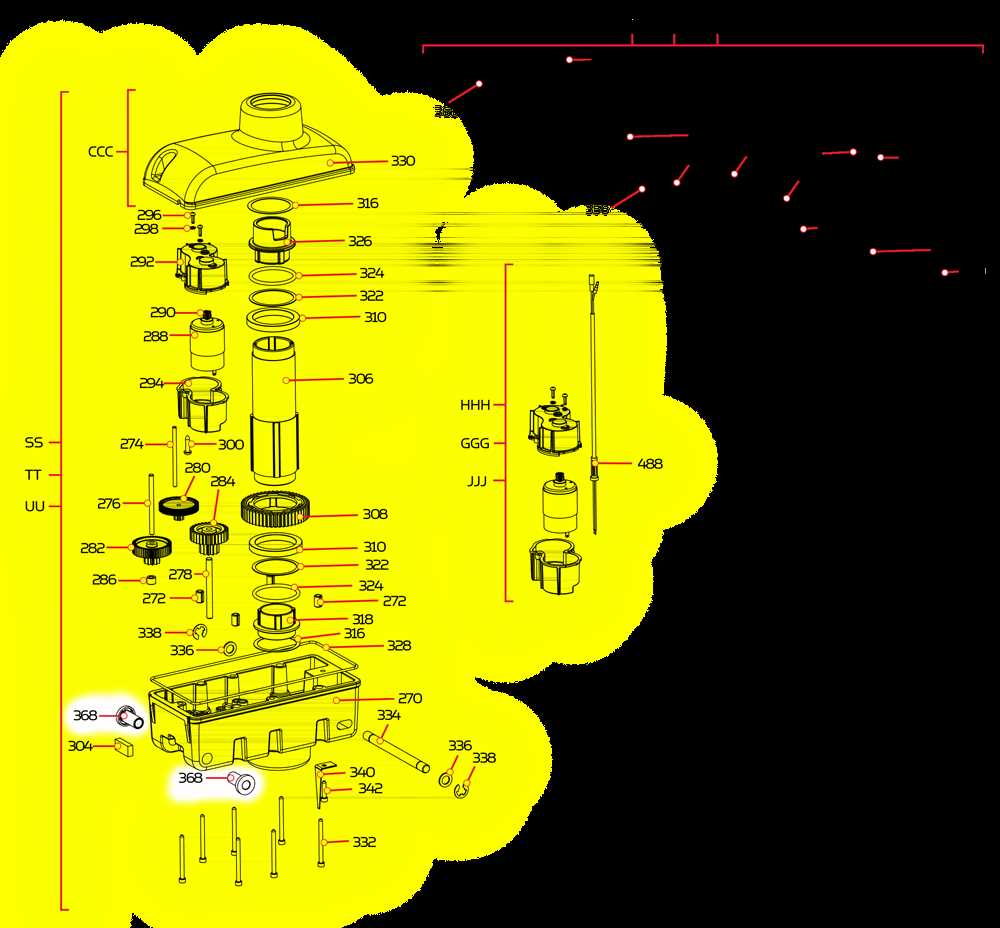

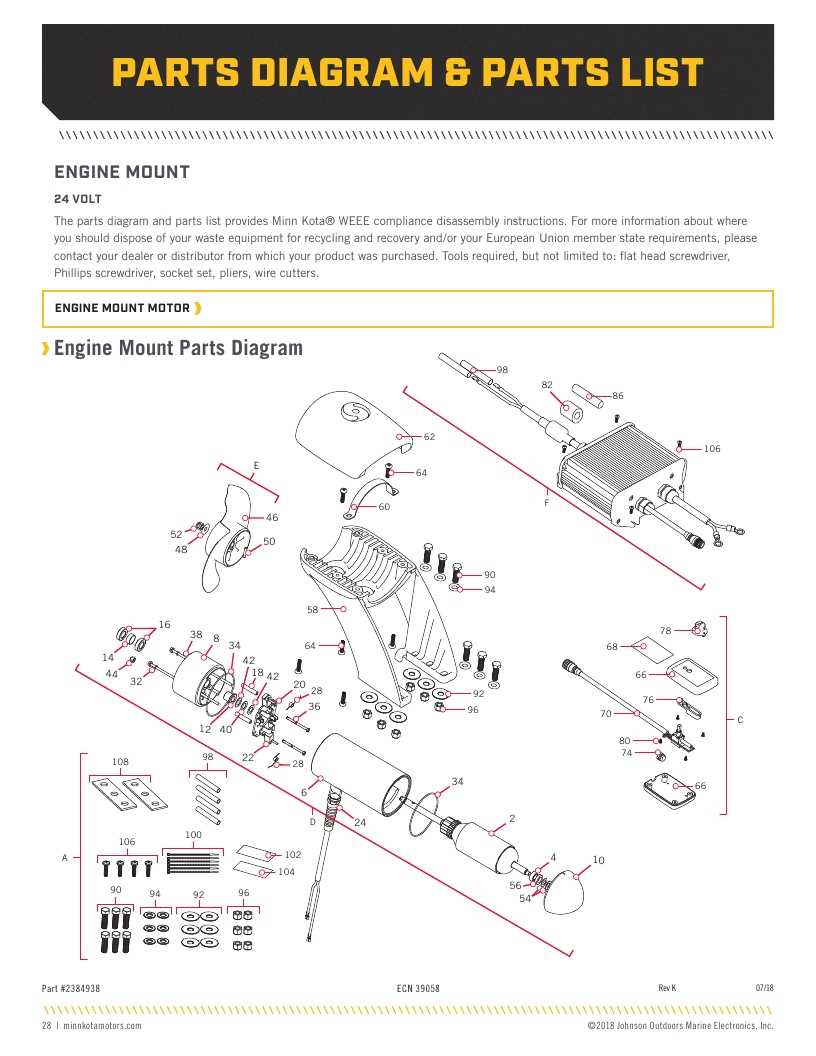

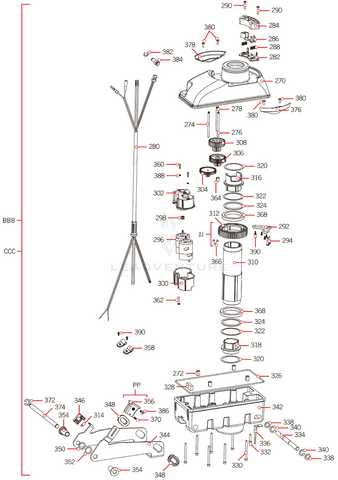

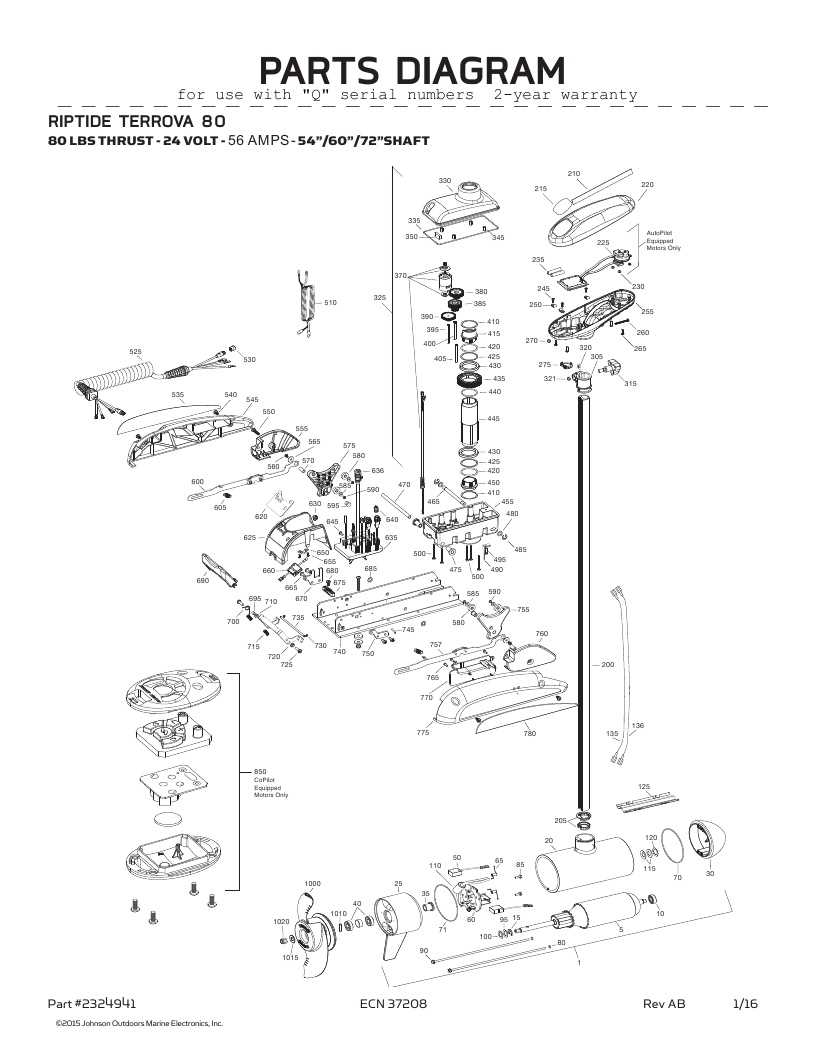

Whether you’re looking to perform routine maintenance or are dealing with a specific issue, visualizing the motor’s structure is a great starting point. In this guide, we’ll break down the essential parts and explain their functions, so you can approach repairs and upgrades with confidence.

Understanding Minn Kota Riptide 80 Components

To effectively maintain and repair your motor, it’s crucial to familiarize yourself with its core elements. Each component plays a vital role in ensuring smooth operation and long-lasting performance. When these components are well understood, you can easily identify issues and carry out necessary repairs or replacements.

The structure of the motor is designed with various interconnected parts, each contributing to its efficiency. From the drive system to the electrical components, every part needs attention to keep the equipment running at its best. Understanding how each piece functions will not only help with diagnostics but also enhance your ability to perform upgrades or modifications as needed.

In this section, we will break down the key elements of your motor, explaining their functions and how they work together. By understanding these components in detail, you can be more proactive in maintaining your motor and prevent unnecessary complications down the line.

How to Identify Riptide 80 Parts

Recognizing the components of your motor can significantly streamline troubleshooting and maintenance. By knowing how to identify each part, you can address issues with precision and avoid unnecessary replacements. This section will guide you on how to spot the main elements of your motor, ensuring you can perform effective repairs.

Visual Inspection

A quick visual check can help you identify any obvious signs of wear or damage. Look for these common issues:

- Loose or missing screws and bolts

- Cracks in the casing or housing

- Worn-out cables or connectors

- Corrosion or rust on metal parts

Consulting the Manual

Your motor’s manual provides detailed images and descriptions of each component. Use it as a reference to cross-check the parts you observe during your inspection. Key elements to focus on include:

- Power unit and its connections

- Control panel and electrical wiring

- Steering and drive systems

- Propeller and its components

By combining these methods, you’ll be able to quickly identify which parts need attention and address any issues effectively.

Maintaining Your Minn Kota Motor

Regular maintenance is essential for keeping your motor running smoothly and extending its lifespan. By conducting routine checks and addressing small issues before they become major problems, you ensure optimal performance in various conditions. This section will provide practical tips for caring for your motor, making maintenance a straightforward task.

Routine Checks

Performing basic inspections on a regular basis can help you catch early signs of damage or wear. Some key maintenance tasks include:

- Inspecting cables and wiring for frays or corrosion

- Cleaning the propeller and drive system to prevent debris buildup

- Checking seals and gaskets to avoid water damage

Proper Storage

When not in use, proper storage is just as important for the longevity of your motor. Always store it in a dry, cool place and away from direct sunlight. Removing the battery during long periods of non-use will also prevent potential issues such as leaks or corrosion. Additionally, consider using a cover to protect the motor from dust and moisture.

By staying on top of these maintenance practices, you can minimize repairs and keep your equipment in peak condition for years to come.